An optimization method for steam turbine agc system

An optimization method and steam turbine technology, applied in geometric CAD, computer-aided design, calculation, etc., can solve the problem that it is difficult to meet the adjustment speed and adjustment accuracy at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

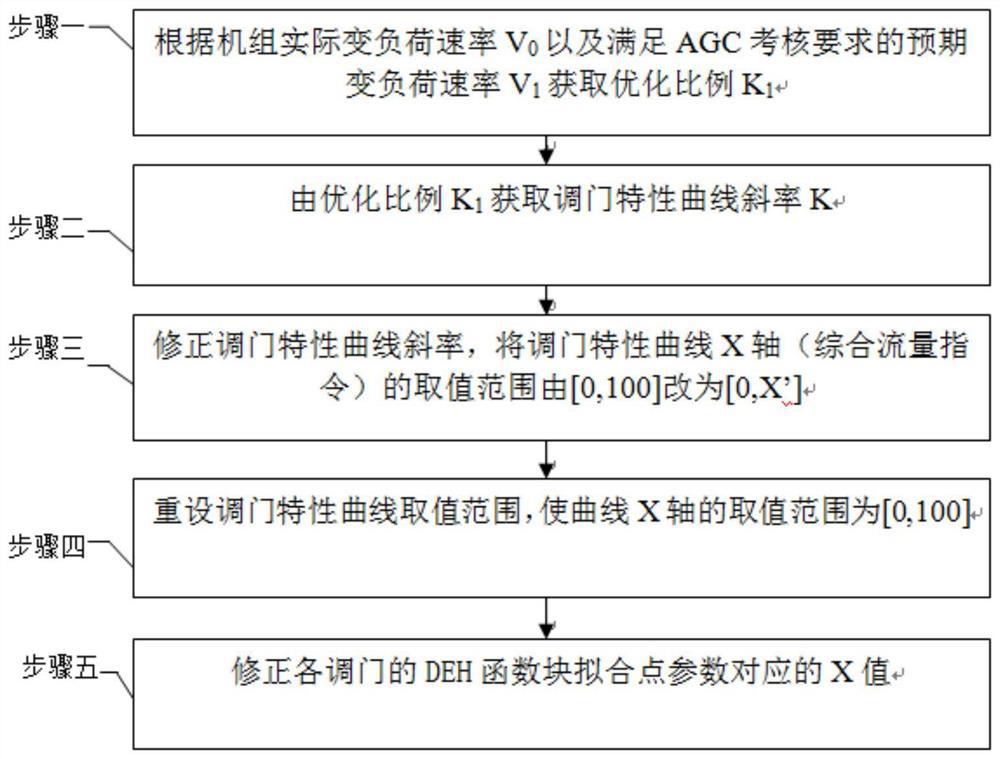

[0032] Specific implementation mode one: as figure 1 Shown, a kind of optimization method of steam turbine AGC system comprises the following steps:

[0033] Step 1: According to the actual variable load rate V of the unit 0 And the expected variable load rate V that meets the requirements of the AGC assessment 1 Get the optimized ratio K 1 ;

[0034] Step 2: According to the optimized ratio K obtained in Step 1 1 Get the slope K of the tuning characteristic curve:

[0035] K=1+K 1

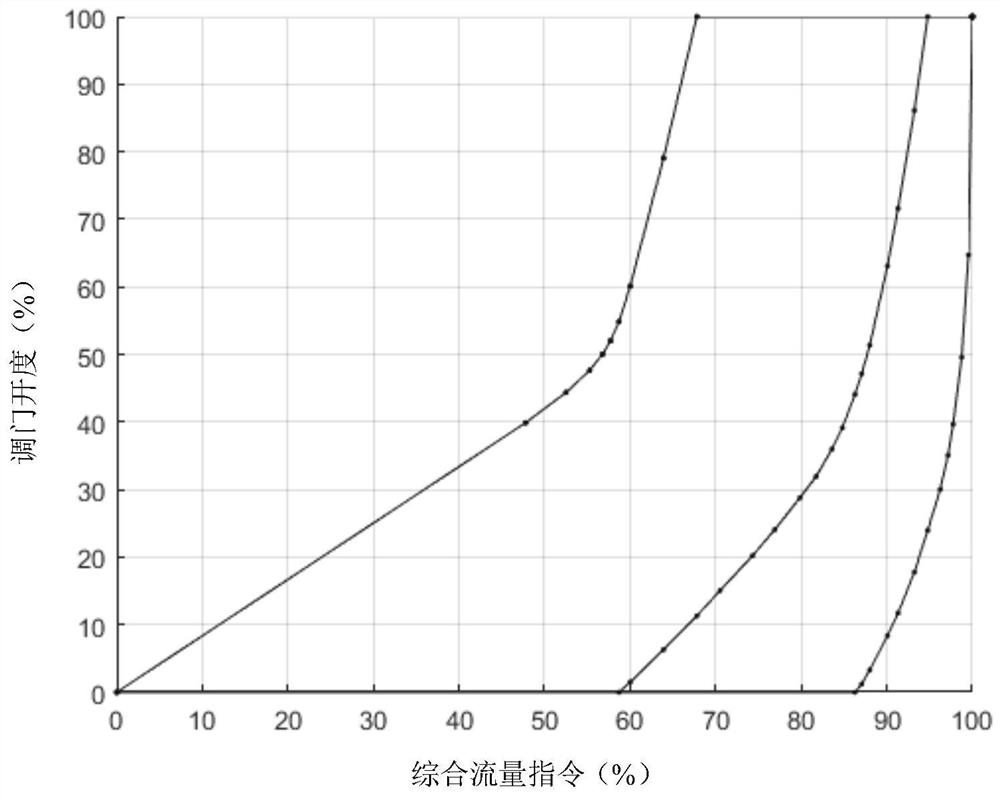

[0036] Step 3: In order to increase the slope of the characteristic curve, change the slope of the characteristic curve of the regulating valve, and change the value range of the X-axis (comprehensive flow command) of the characteristic curve of the regulating valve from [0,100] to [0,X’], where:

[0037]

[0038] Step 4: Translate the tuning characteristic curve as a whole, so that the value range of the X-axis of the tuning characteristic curve is [0,100];

[0039] Step 5: Correct the...

specific Embodiment approach 2

[0045] Specific embodiment two: the difference between this embodiment and specific embodiment one is that: in the step one, according to the actual variable load rate V of the unit 0 And the expected variable load rate V that meets the requirements of the AGC assessment 1 Get the optimal ratio K 1 Specifically:

[0046]

[0047] Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in the step 4, the overall translation distance X of the adjustment characteristic curve is translated. L for:

[0049] x L = 100-X'.

[0050] Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com