Punching and painting assembly line online visual monitoring method based on industrial cloud

A visual monitoring and assembly line technology, applied in the energy industry, comprehensive factory control, comprehensive factory control, etc., can solve the problems of inconvenient single-person operation of long-distance assembly lines, and achieve the goals of saving energy, increasing monitoring frequency, and improving quality control capabilities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to better understand the technical solution of the present invention, the following will be described in detail through specific examples:

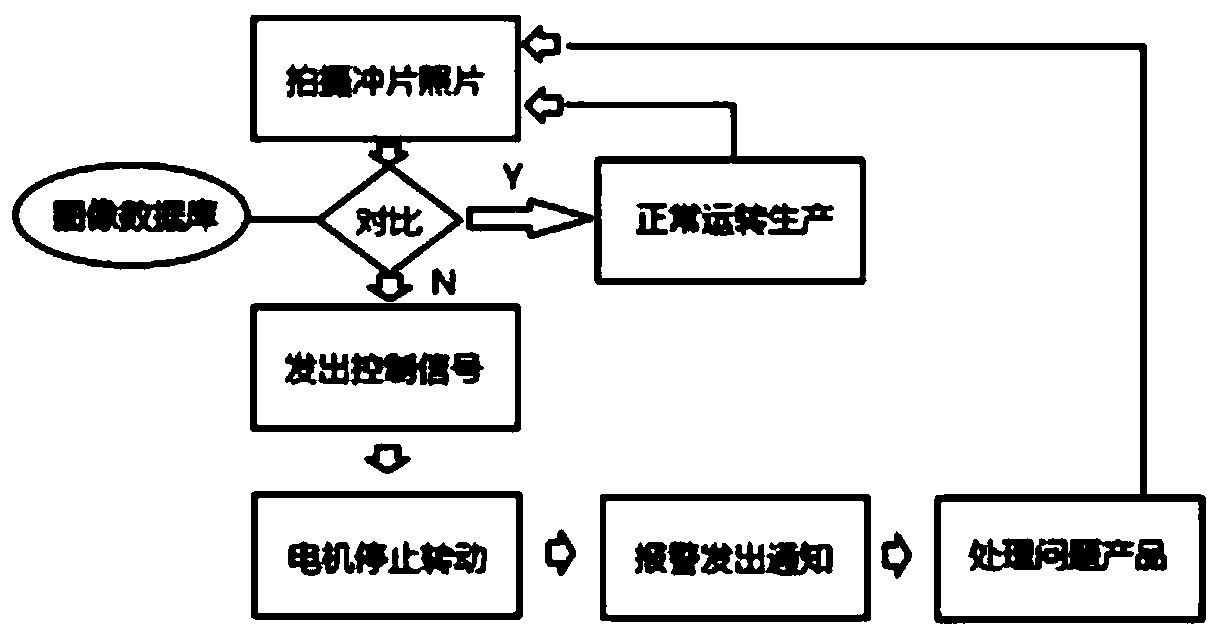

[0017] see figure 1 , a kind of online visual monitoring method of the punching and painting line based on the industrial cloud of the present invention comprises the following steps:

[0018] In step A, collect the print pattern of the work area through the high-definition camera in the monitoring area.

[0019] Step B, transforming the photographs taken by the integrated controller to form a processing pattern with characteristic parameters of the marked area.

[0020] In step C, compare the processed pattern with the reference pattern in the image database. If it is normal, end the round of monitoring, and start the next round of stamping and painting from step A. If a stamping defect is found, execute step D.

[0021] In step D, technical and quality control personnel send out control signals to stop the equipment mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com