Maintenance decision-making method based on power generation equipment operation state comprehensive evaluation model

A technology of power generation equipment and operating status, which is applied in the direction of calculation models, instruments, data processing applications, etc., and can solve problems such as unsatisfactory equipment operation and maintenance decisions, single status division levels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] The invention relates to a maintenance decision-making method based on a comprehensive evaluation model of the operating state of power generation equipment, including the state of the power generation equipment, where n mutually independent characteristic values representing the state of the power generation equipment are respectively x 1 (t),x 2 (t),...,x n (t), since they come from the same object, they are considered together as a whole, and they form an m-dimensional vector, called the state feature vector of the device, denoted as

[0058] x=[x 1 ,x 2 ,...,x n ] T

[0059] The n-dimensional space formed by all possible values of the state feature vector x at time t is called the state feature space, denoted as X n ;

[0060] The power generation equipment status consists of the following categories of characteristics:

[0061] 1) The characteristics of the output parameters, which reflect the current operating status of the equipment. Such characteris...

Embodiment 2

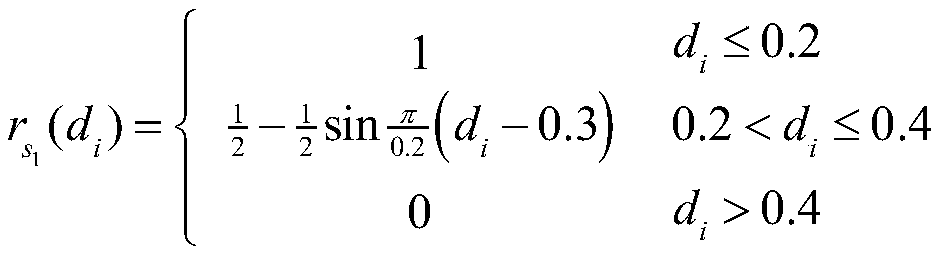

[0066] On the basis of Embodiment 1, it also includes the establishment of a state evaluation model for power generation equipment. In order to accurately describe the state of the equipment, quantitative indicators are used to describe different degradation states. After the equipment state feature space is established, the state evaluation is based on some It can reflect the characteristic index of the working performance of the equipment, and adopt an appropriate model to determine the current deterioration degree of the equipment.

Embodiment 3

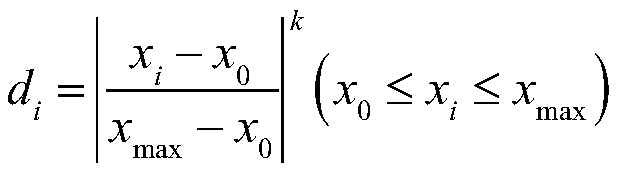

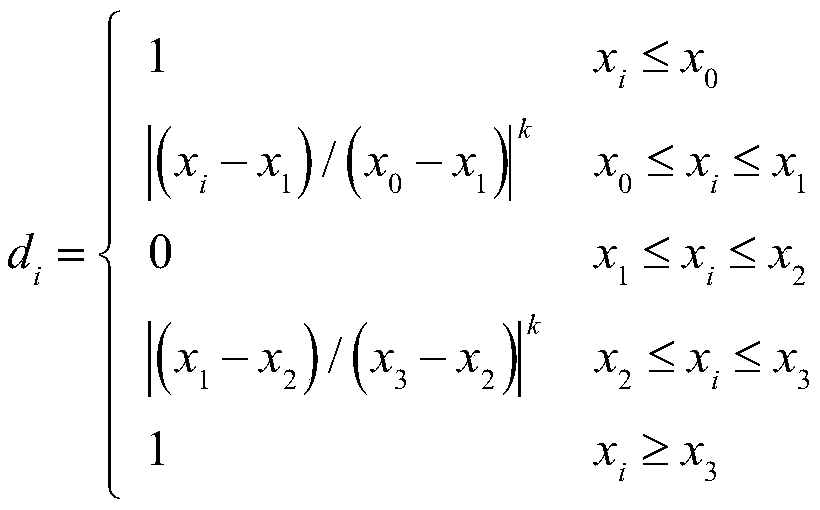

[0068] On the basis of Embodiment 1-2, it also includes the determination of the state evaluation index of power generation equipment—deterioration degree, each equipment has a series of state parameters x that characterize its ability to achieve specific performance 1 ,x 2 ,...,x n , and they are functions of time, which can be written as x i (t), the ability of the device to achieve its specific performance can be considered as n characteristic parameters x i (t) the set of normal states determined, while faults and failures are x i (t) A set that exceeds the limit of the normal state. According to the reliability theory, the degree of deterioration can be used to indicate that the equipment deviates from the normal state x i (t) degree, denoted as d i , and its value range is [0,1]. When the degree of deterioration is 1, the surface equipment is in a fault state; when the degree of deterioration is 0, it indicates that the equipment is in the optimal state. According to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com