Power battery and preparation method thereof

A power battery and rolling core technology, which is applied in the field of power batteries and their preparation, can solve the problems of battery energy density, battery cycle life, etc., and achieve the effects of increasing energy density, improving cycle life, and increasing size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

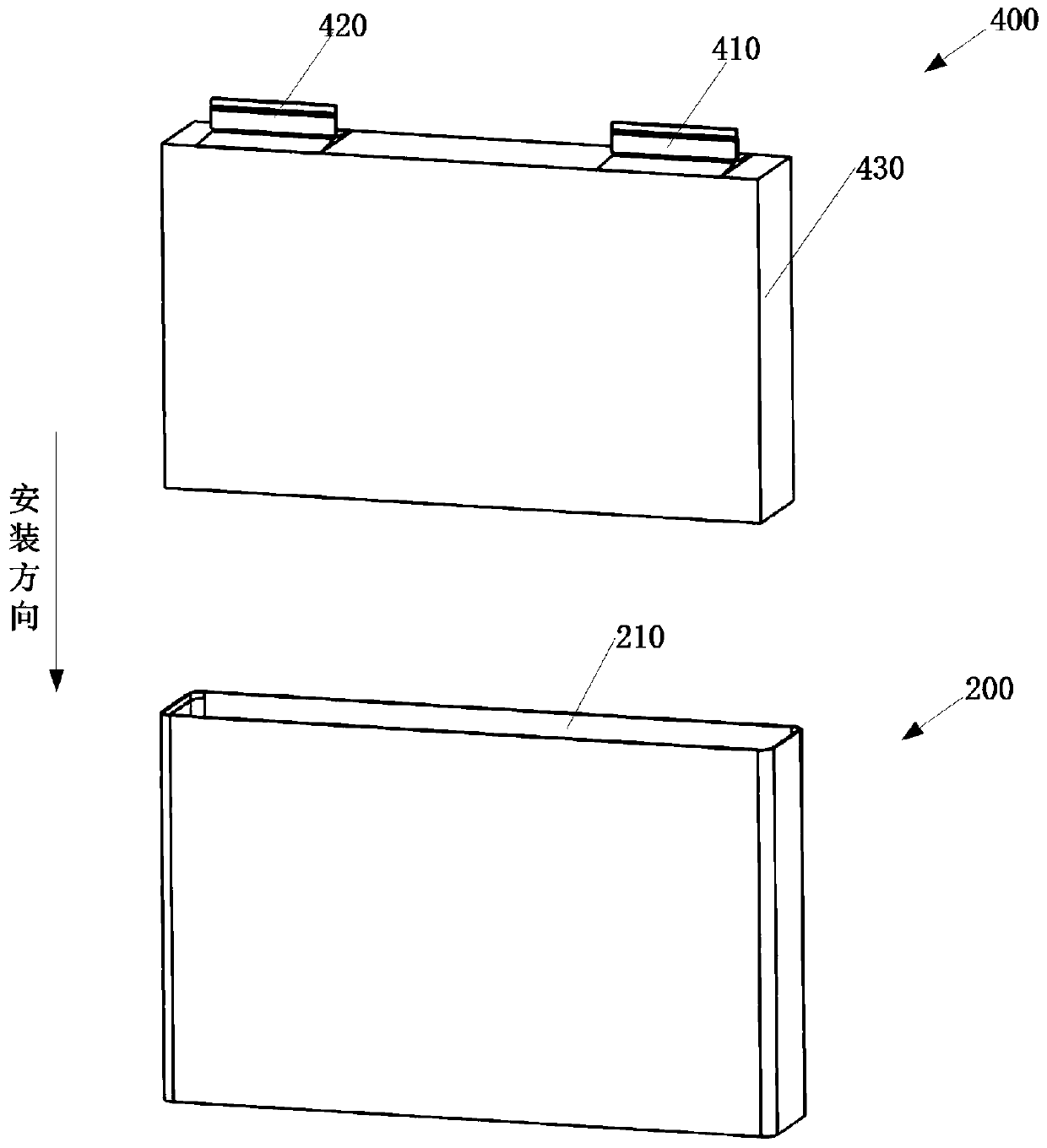

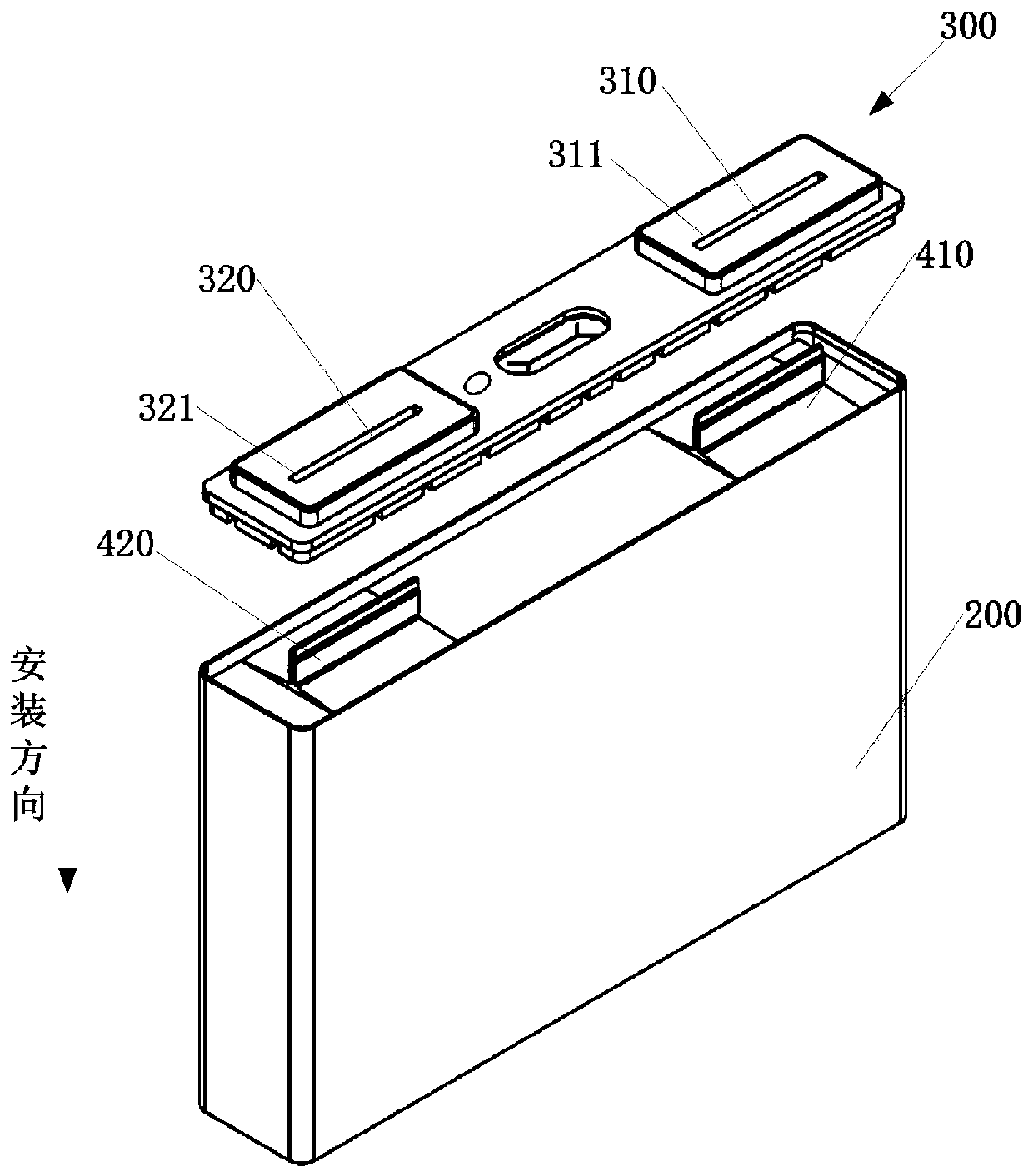

[0058] The present application also discloses a method for preparing a power battery, which includes the following steps: Step S200, preparing a single winding core; step S300, assembling the single winding core to the casing of the power battery; step S400, providing a cover plate ; Step S500, passing the positive tab of the winding core and the negative tab of the winding core through the first through-type guide groove and the second through-type guide groove respectively; Step S600, into the casing of the power battery Inject electrolyte; step S700, assembling the cover plate to form the power battery. Compared with the traditional technical solution, the power battery prepared by the invention and its preparation method has higher energy density, smaller internal resistance, lower temperature rise and longer cycle life.

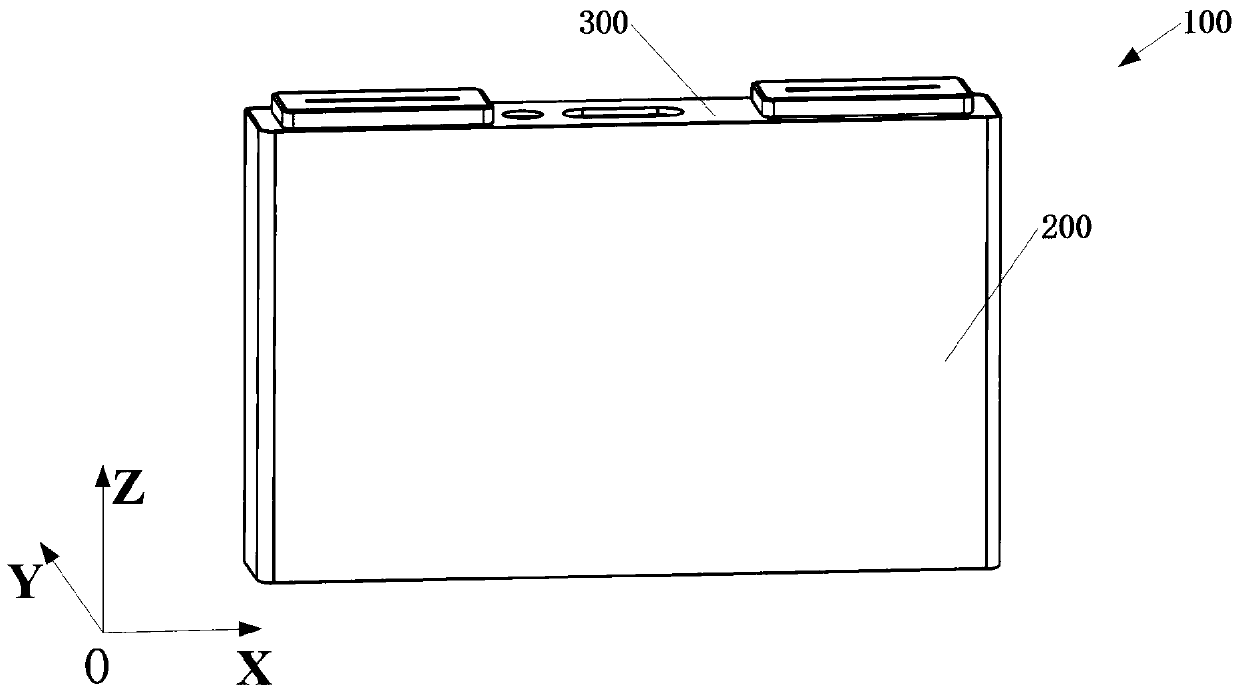

[0059] Figure 8 It is a schematic structural diagram of a power battery 100 according to an embodiment of the present application.

[0060] Referring...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com