A rotor intermediate ring structure and design method thereof

An intermediate ring and rotor technology, applied in the field of cage induction motor design, can solve problems such as differences in design methods, current characteristics of the intermediate ring, and heat dissipation conditions, and achieve uniform heat dissipation distribution, increased processing difficulty, and uniform heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and should not be construed as limiting the protection scope of the application. Those skilled in the art can The above application content makes some non-essential improvements and adjustments to this application.

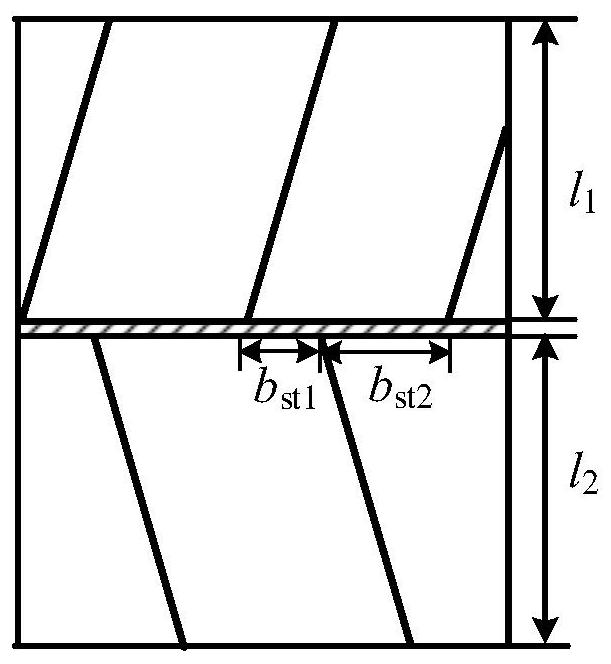

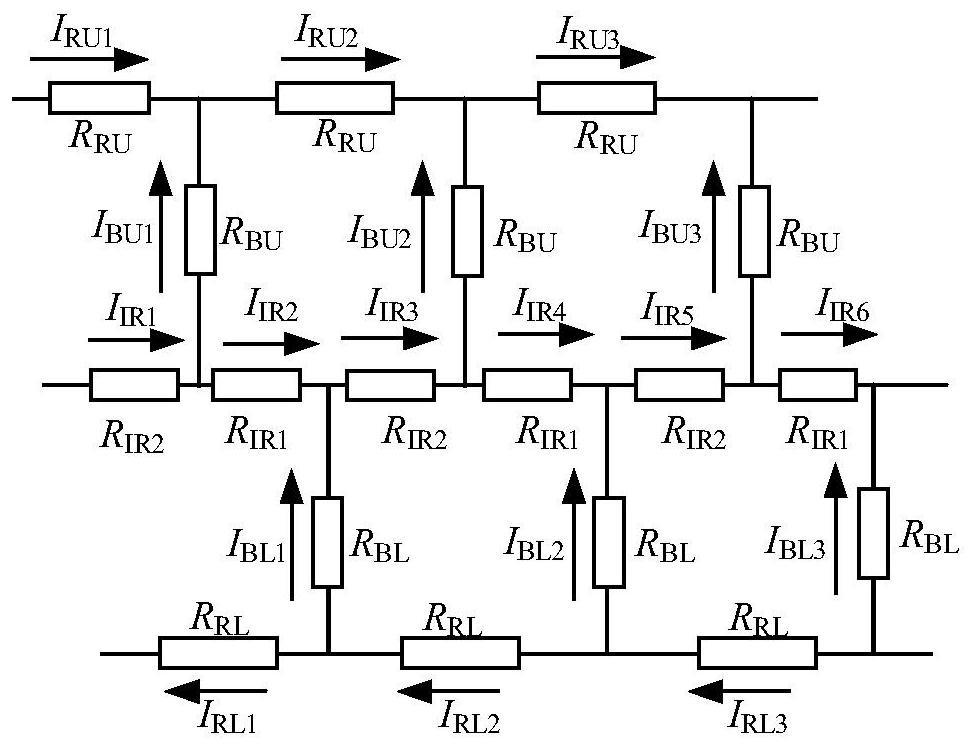

[0043] like image 3 A rotor intermediate ring structure is shown, including an intermediate ring body, and the axial height of the intermediate ring body is: l IR ∈(0,l R / 3], where: l R is the axial height of the end ring. The radial width of the intermediate ring body is: b IR ∈[3b t2 / 4,(D2 -D 0 +6b t2 ) / 8], where: b t2 is the rotor slot height, D 2 is the outer diameter of the rotor, D 0 is the inner diameter of the rotor.

[0044] A method for designing a rotor intermediate ring structure, comprising the following ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com