A wrinkled frame mechanism for matching photovoltaic modules and its preparation process

A photovoltaic module and frame technology, applied in photovoltaic modules, photovoltaic power generation, metal material coating technology, etc., can solve the problems of backward oxidation process and non-compliance with process requirements, so as to ensure the performance of pressure resistance and reduce the risk of test failure. The effect of increasing the load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

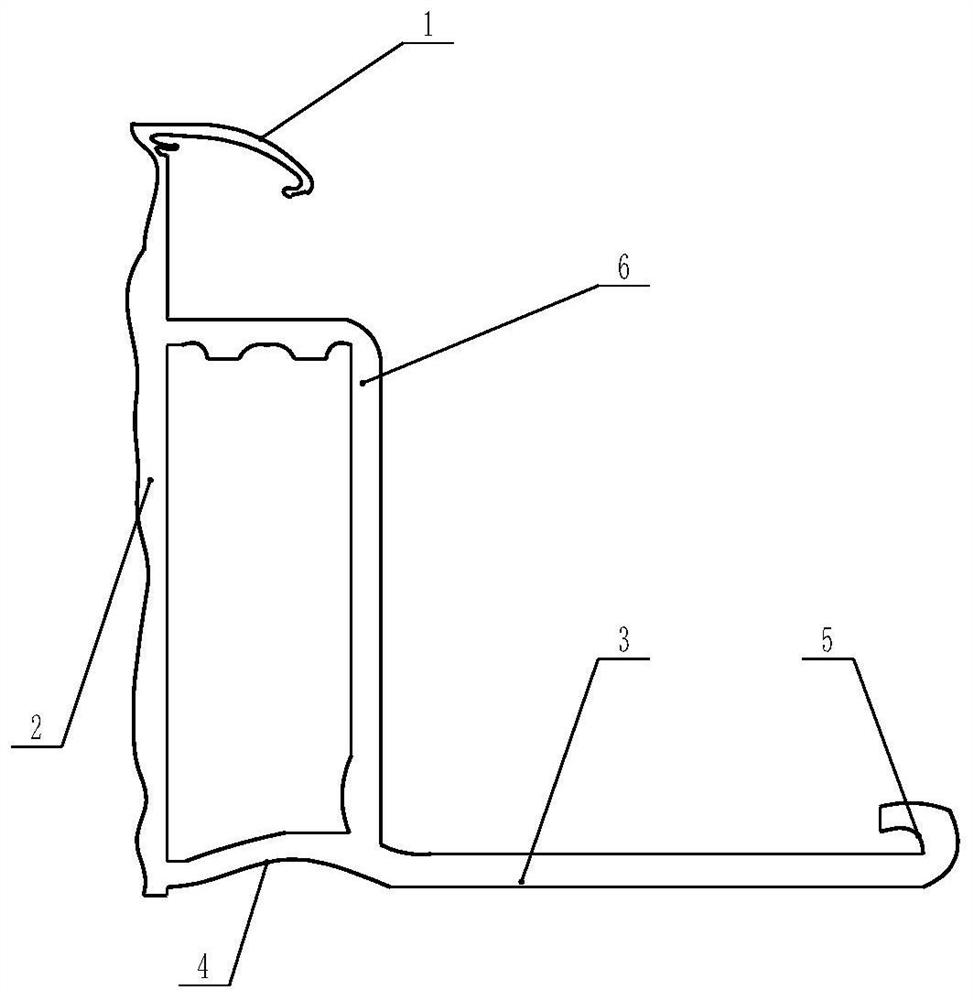

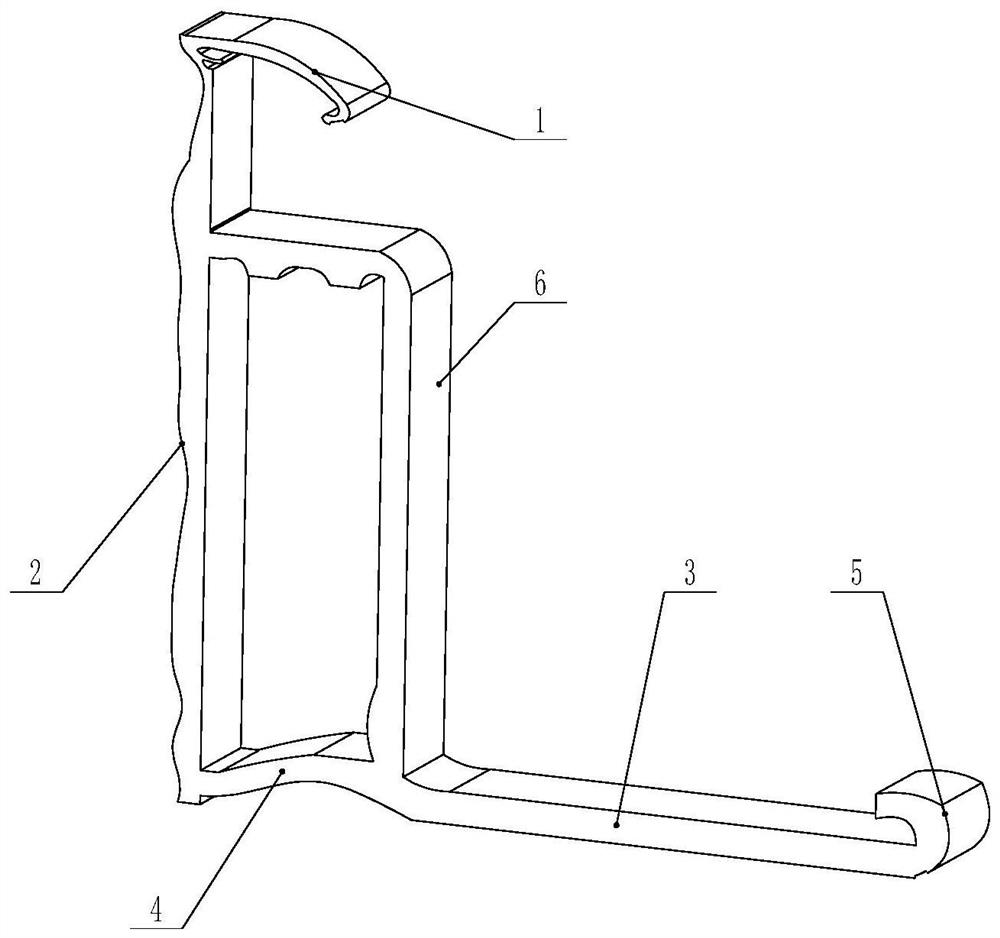

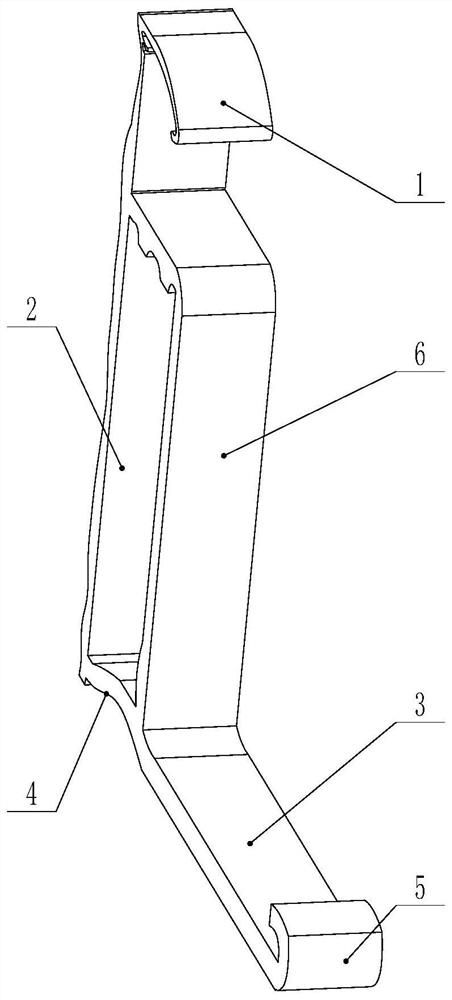

[0042] Example 1, such as figure 1 As shown, a folded frame mechanism for matching photovoltaic modules is provided, including a frame body for matching with photovoltaic modules. The closed shape includes a rectangular closed enclosure, a circular closed enclosure, an elliptical closed enclosure, and a special-shaped closed enclosure. The two ends of the corner are respectively extended to the corresponding arms of the outer wall to form a closed tubular structure with a cavity. The tubular structure is a tubular structure with a hollow cavity in the center; The wall surface is provided with continuous concave-convex pleats for increasing deformation resistance, and the pleats are continuous arc-shaped concave-convex.

[0043] Such as figure 1 with figure 2As shown, the outer wall part includes A surface segment, B surface segment, and C surface segment that are continuously connected. C surface section>A surface section.

[0044] The A surface section is at the top, an...

Embodiment 2

[0046] Example 2, such as Figure 4 as shown figure 1 As shown, a folded frame mechanism for matching photovoltaic modules is provided, including a frame body for matching with photovoltaic modules. For enclosure, circular enclosure, ellipse enclosure, and special-shaped enclosure, the frame main body includes an outer wall part bent in multiple sections, and an inclusion-shaped corner part is provided at the inner corner of the outer wall part, The two ends of the corner extend to the corresponding arms of the outer wall respectively to form a closed tubular structure with a cavity. The tubular structure is a tubular structure with a hollow cavity in the center; It is deformed into a continuous concave-convex wrinkle configuration, and the wrinkle configuration is a continuous arc-shaped concave-convex shape.

[0047] Such as figure 1 with figure 2 As shown, the outer wall part includes A surface segment, B surface segment, and C surface segment that are continuously con...

Embodiment 3

[0050] Embodiment 3 provides a folded frame mechanism for matching photovoltaic modules, including a frame body for matching with photovoltaic modules. The frame body is a rod-shaped linear long extension body, and a closed curve encloses a rectangle Closed enclosure, circular enclosed enclosure, elliptical enclosed enclosure, and special-shaped enclosed enclosure, the frame body includes an outer wall portion bent in multiple sections, and an enclosed corner portion is provided at the inner corner of the outer wall portion , the two ends of the corner extend to the corresponding arms of the outer wall to form a closed tubular structure with a cavity. The tubular structure is a tubular structure with a hollow cavity in the center; There is a continuous concave-convex wrinkle configuration for increasing deformation resistance, and the wrinkle configuration is a continuous arc concave-convex shape.

[0051] Such as figure 1 with figure 2 As shown, the outer wall part include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com