Flax wet-spinning machine

A wet-spinning spinning frame and flax technology, which is applied to spinning machines, continuous winding spinning machines, textiles and papermaking, etc., can solve the problems of low efficiency of manual replacement of bobbins, achieve good market prospects, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

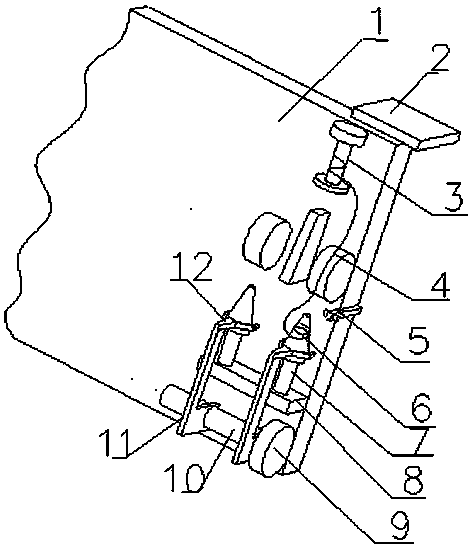

[0015] Flax wet-spinning spinning machine, including machine base 1, controller 2, roving wheel 3, stretching wheel 4, laser cutter 5, bobbin 6, rotating shaft 7, horizontal plate 8, gear motor 9, transmission shaft 10, The turret 11 and the mechanical gripper 12 are characterized in that: a controller 2 is installed on the top of the machine base 1 to control the operation of the whole machine, and a roving wheel 3 is installed under the controller 2, which is a raw material component; Stretch wheel 4 is installed, is used for stretching raw material, changes existing parts, and stretch wheel 4 below is installed with bobbin 6, is installed with rotating shaft 7 in bobbin 6, is provided with drive in rotating shaft 7 The motor is used to drive the bobbin 6 to rotate; the rotating shaft 7 is fixed on the horizontal plate 8, generally 50 are arranged to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com