Detergent box and washing machine

A detergent box and detergent technology, applied in the field of washing machines, can solve the problems of contamination of detergent accommodation units, detergent hardening, etc., and achieve the effects of improving delivery efficiency, reducing amplitude, and reducing bacterial growth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

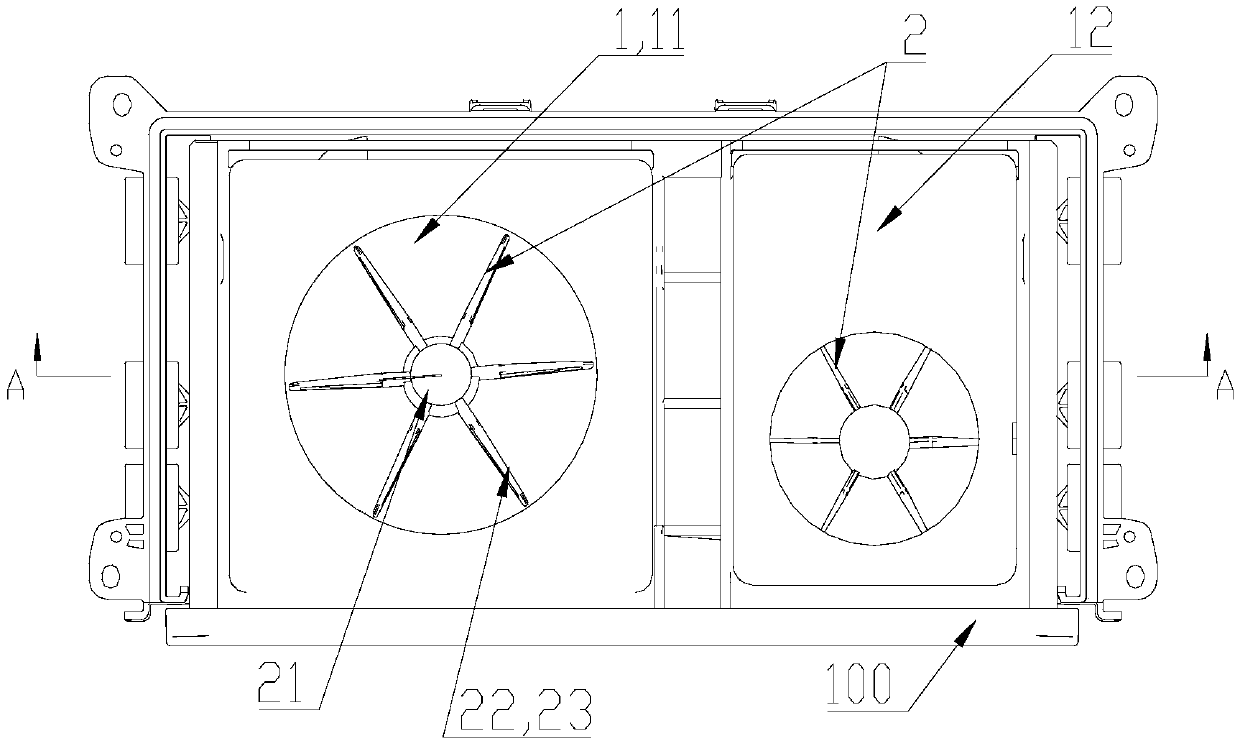

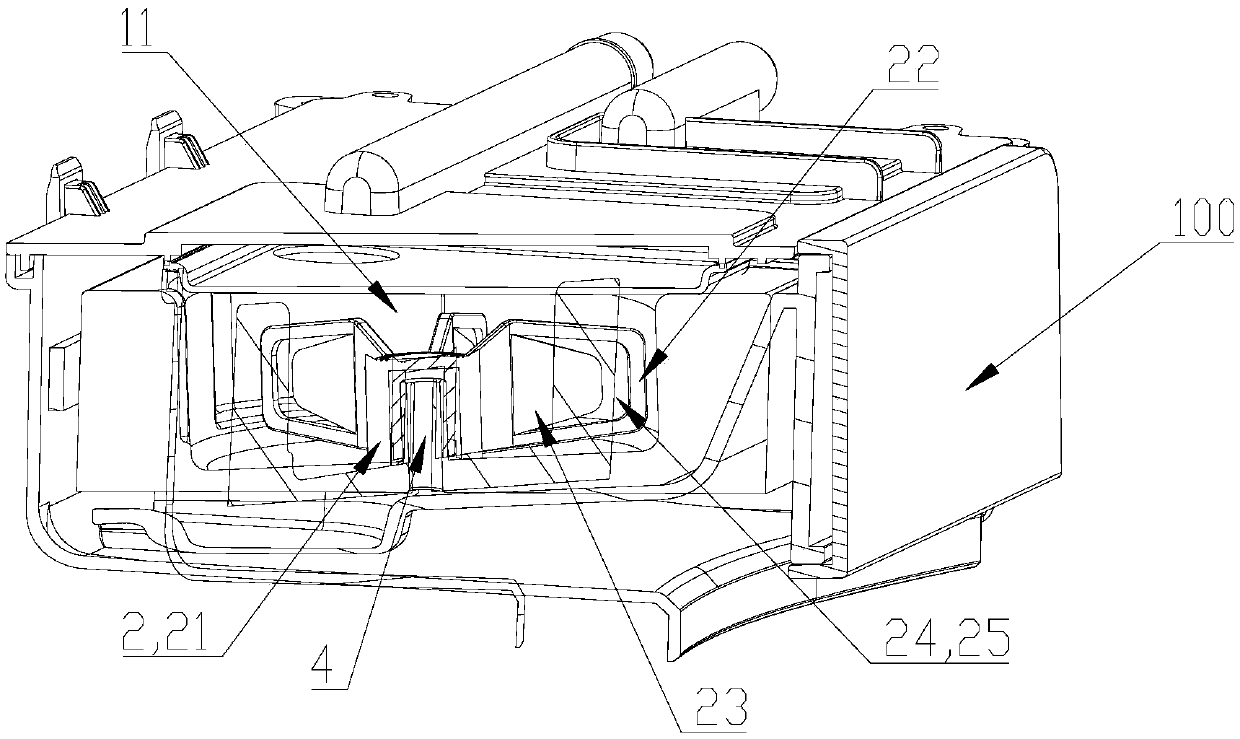

[0042] like Figure 1 to Figure 4 As shown, a detergent box 100 is introduced in this embodiment, and the detergent box 100 includes an accommodating chamber 1 with a hollow interior for accommodating detergent and / or softener, etc. The runner 2 is used to dissolve detergent or softener, etc. The runner 2 includes a runner shaft 21 located at the center of the runner and blades 22 extending radially along the runner shaft. Hollow parts 25 are provided on the blades.

[0043] In this embodiment, the interior of the accommodation chamber 1 is hollow and the top is open. The detergent and / or softener etc. are put into the accommodation chamber 1 through the open top, and the detergent and softener are rotated through the rotating wheel arranged in the accommodation chamber 1. / or the softener is dissolved in the accommodation chamber 1 .

[0044] In this embodiment, the runner 2 is arranged at the center of the chamber 1 and coaxially arranged with the chamber 1. The runner 2 in...

Embodiment 2

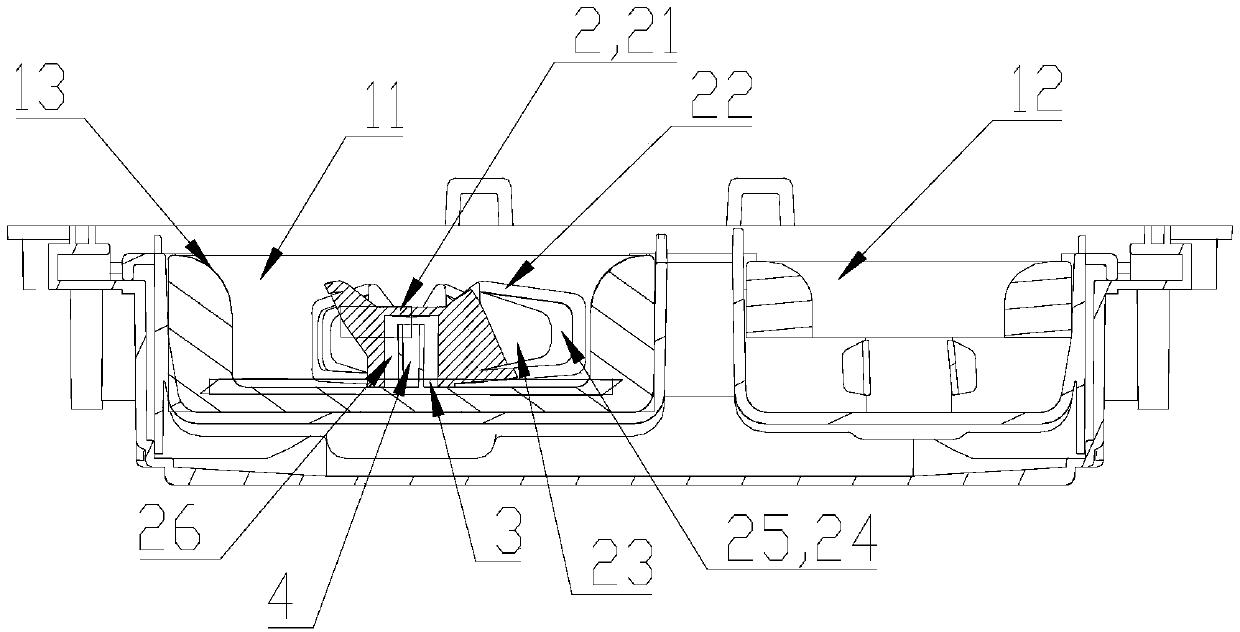

[0051] like Figure 1 to Figure 4 As shown, in this embodiment, a siphon tube 4 protruding upward is provided at the bottom of the storage chamber 1 for discharging the detergent / softener etc. inside the storage chamber 1 to the outside of the storage chamber 1 .

[0052] In this embodiment, the center of the bottom end of the containing chamber 1 is provided with a siphon tube 4 protruding upwards, and the inside of the runner shaft 21 is hollow to form a hollow chamber 26, and the siphon tube 4 is vertically embedded in the hollow chamber 26 of the runner shaft 21 .

[0053] In this embodiment, the bottom end of the siphon tube 4 passes through the accommodating chamber 1 and communicates with the drainage structure of the detergent box 100. The top of the chamber 26 is connected, and the bottom end of the hollow chamber of the runner shaft 21 is provided with a water inlet 3 connected with the containing chamber 1, so that the containing chamber 1 is connected with the sip...

Embodiment 3

[0055] like Figure 1 to Figure 4 As shown, a detergent box 100 is introduced in this embodiment, which includes a box body and an accommodating chamber 1 which is arranged in the box body, is hollow inside and is used to accommodate detergent / or softener, etc., and the accommodating chamber 1 is in the shape of a cylinder structure. By arranging a cylinder-shaped accommodation chamber, the flushing dead angle in the chamber is reduced, and the efficiency of detergent delivery in the chamber is improved, thereby avoiding the residue of detergent, reducing the resulting bacterial growth, and improving the cleaning efficiency. Detergent utilization.

[0056] In this embodiment, the interior of the accommodation chamber 1 is hollow, the top is open, and the axis is vertically arranged. Any horizontal cross-section of the accommodation chamber 1 is a circle with equal diameters. The connection is set as an arc chamfer 13; preferably, the connection between the bottom of the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com