Power battery thermal runaway protection method, device and system

A power battery and protection system technology, applied in the field of vehicle safety, can solve problems such as extrusion, puncture, thermal runaway accidents, effective handling, and insufficient reliability, and achieve the effect of avoiding expansion and thermal runaway accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

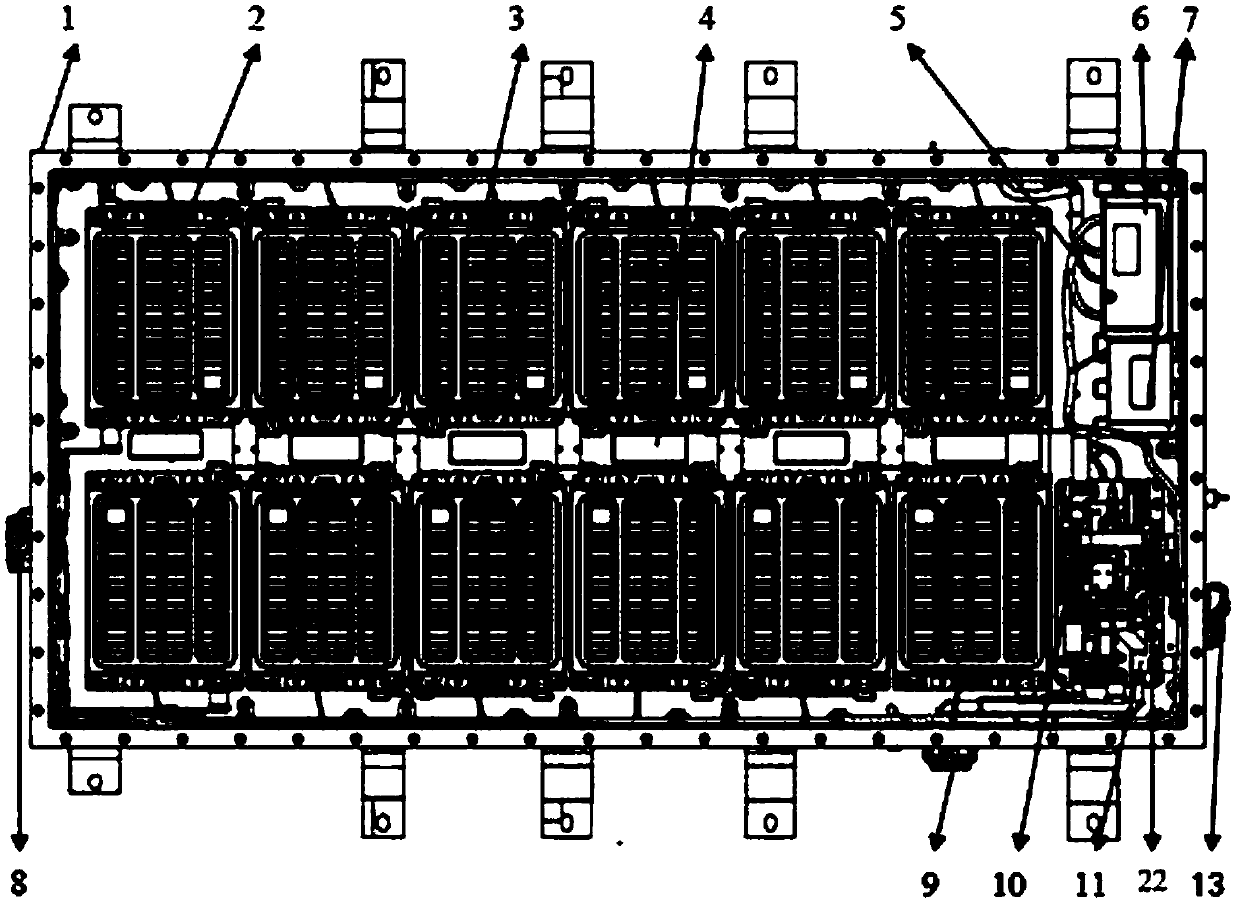

Image

Examples

Embodiment Construction

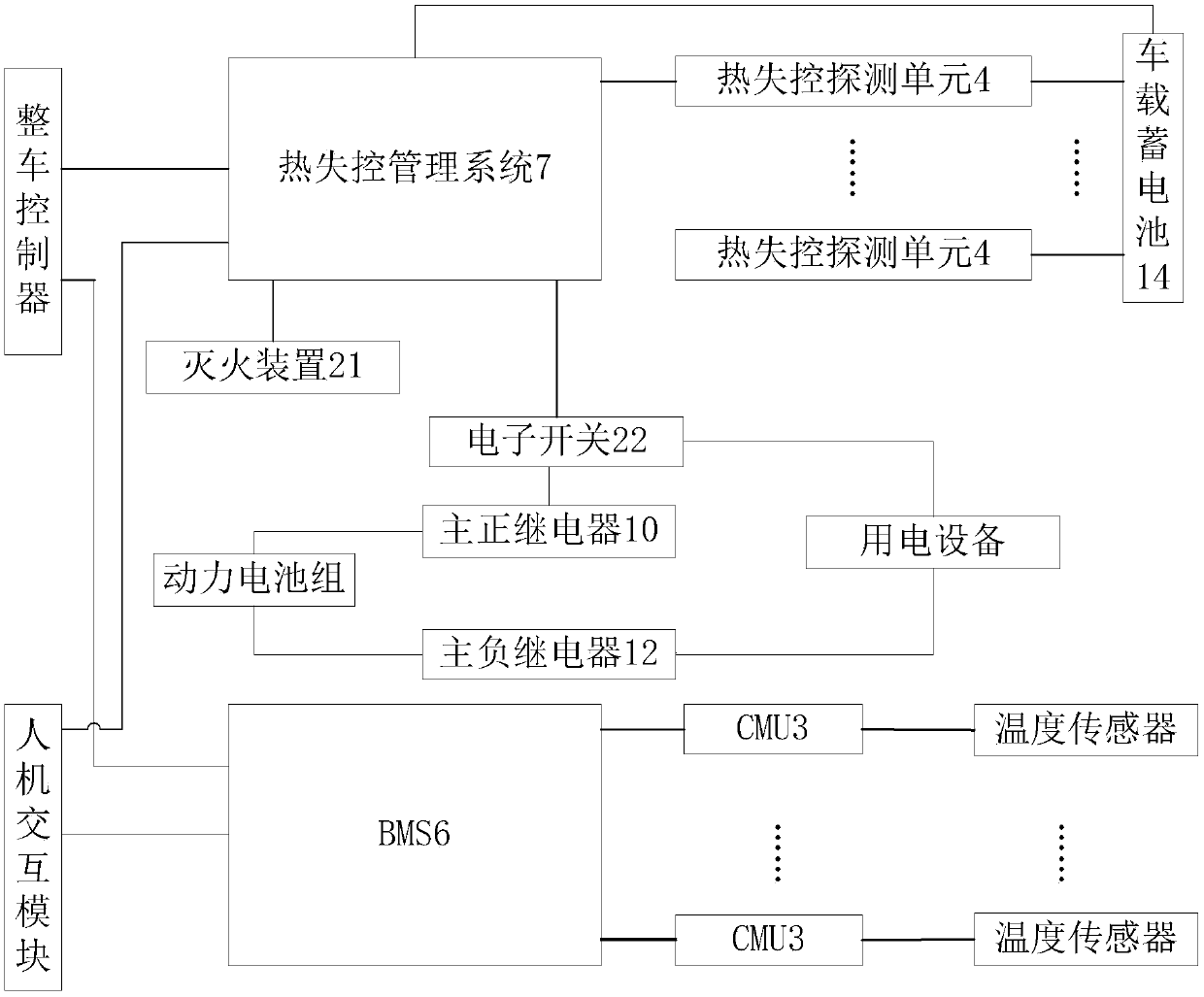

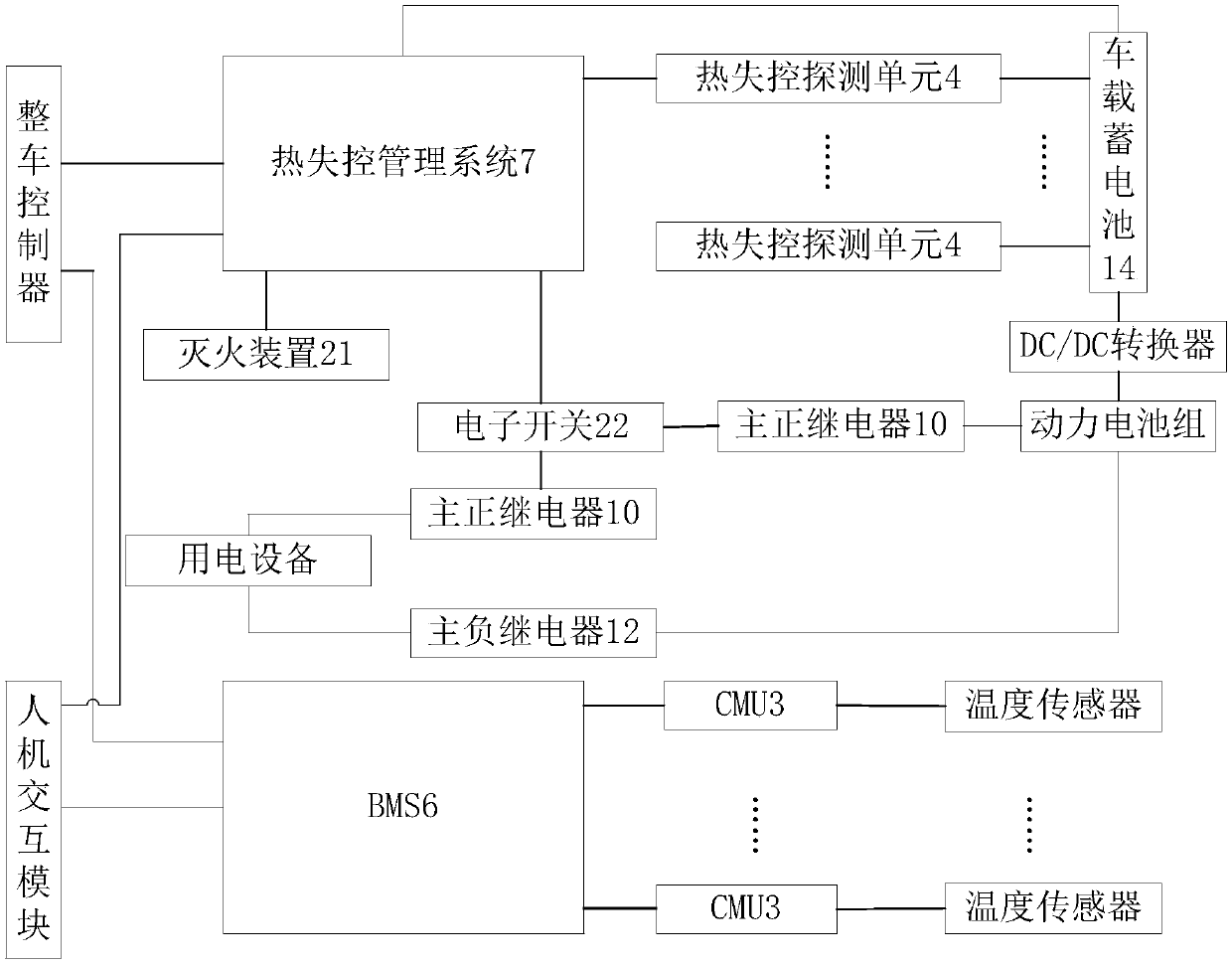

[0045]In order to solve the problem that the BMS cannot monitor the power battery pack to prevent thermal runaway when the vehicle is powered off. The present invention monitors the power battery pack when the vehicle is powered off by setting a thermal runaway management system, and then cuts off the power output of the power battery pack in time when the power battery pack has thermal runaway and implements fire extinguishing on the power battery pack through the fire extinguishing device In order to avoid the expansion of thermal runaway accidents; further, by connecting the electronic switch in series with the power output circuit of the power battery pack and controlled by the thermal runaway management system, when the main relay of the power output circuit of the power battery pack has a sticking failure, Ensure that the power output of the power battery pack is cut off; and the thermal runaway detection of the power battery pack is also performed through the thermal run...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com