Assisted joint training device and method

A training device and joint technology, applied in passive exercise equipment, physical therapy and other directions, can solve the problems of non-adjustable training intensity, secondary injury, increased patient pain, etc., and achieve the effect of complete functions, good applicability and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

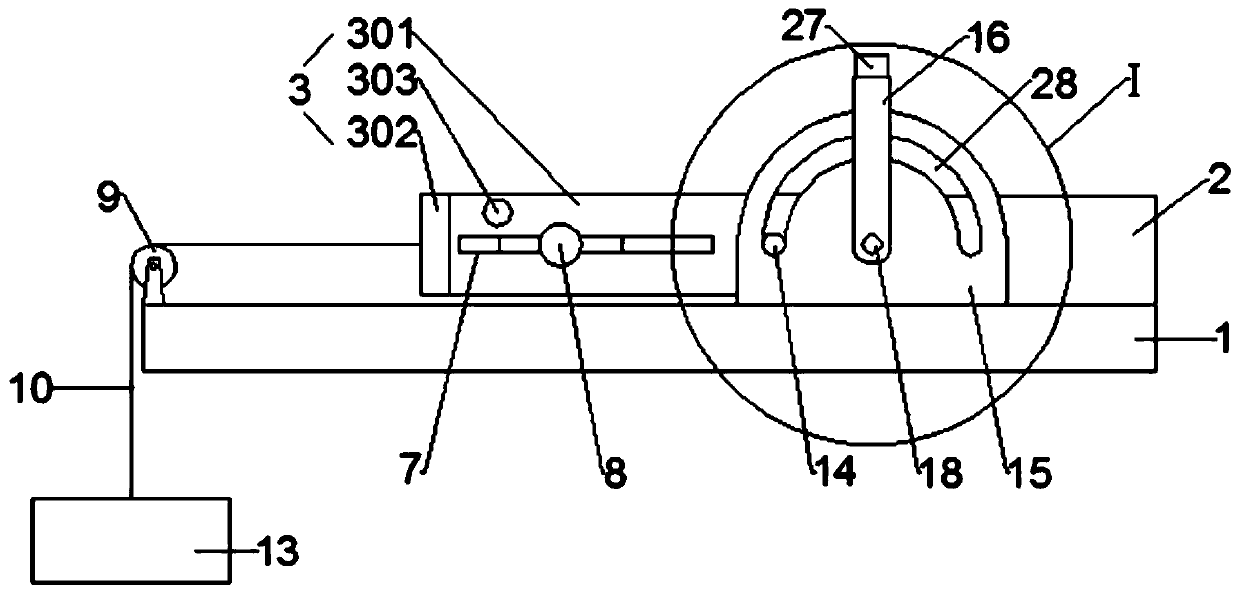

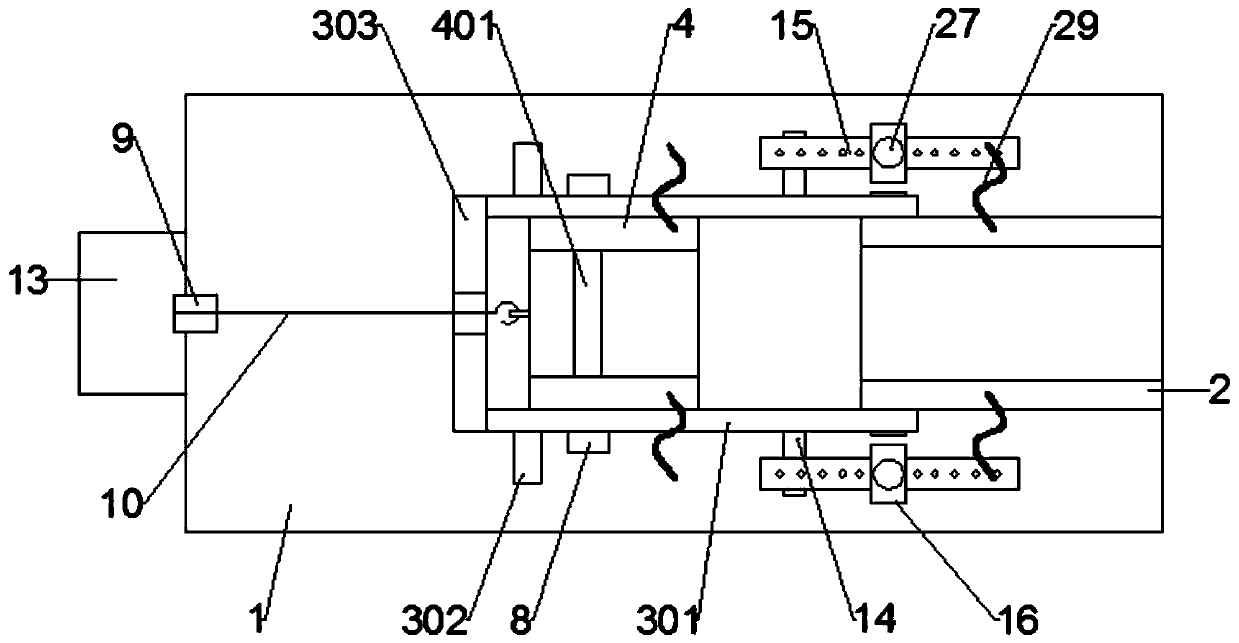

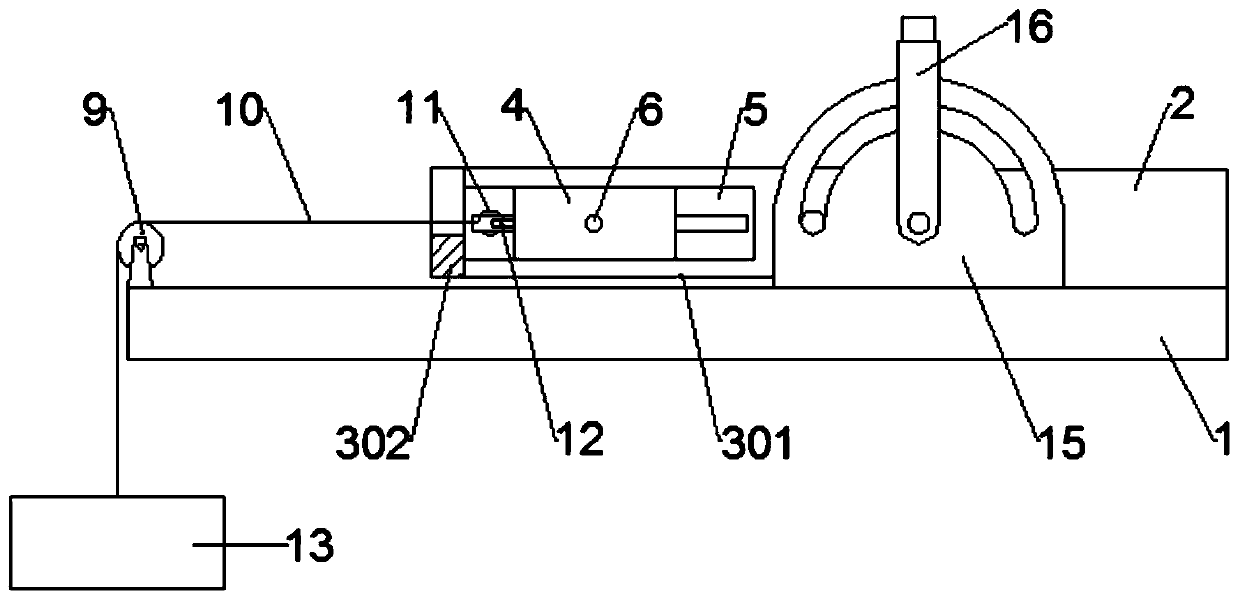

[0029] Such as Figure 1 to Figure 7 As shown, a joint auxiliary training device includes a base plate 1, a large arm holder 2 is fixedly installed on the base plate 1, a forearm support 3 is rotatably installed on the large arm support 2, and the forearm support 3 A forearm holder 4 is movably installed on the top, and the upper arm holder 2 and the forearm holder 3 are provided with arc-shaped grooves for placing arms, and the front and rear sides of the arc-shaped grooves are provided with binding belt 29, and a hand grip 401 is also fixedly installed in the arc groove of the forearm holder 4; a forearm holder locking mechanism is provided between the forearm support 3 and the forearm holder 4, so The base 1 is provided with a small arm fixing seat traction mechanism, and the base 1 is also provided with a small arm support rotation limiting mechanism.

[0030] The forearm support 3 includes two support arms 301 oppositely arranged on the front and rear sides of the boom f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com