Improved vertical flow sedimentation tank

A vertical flow sedimentation tank, an improved technology, is used in sedimentation separation, flocculation/sedimentation water/sewage treatment, sedimentation tanks, etc., which can solve the problem that the sludge cannot be discharged in time and effectively, the sludge viscosity is large, and the continuity of sludge discharge is affected. and sludge discharge efficiency, etc., to ensure the effect of water purification, avoid sludge clogging, and ensure sludge discharge efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

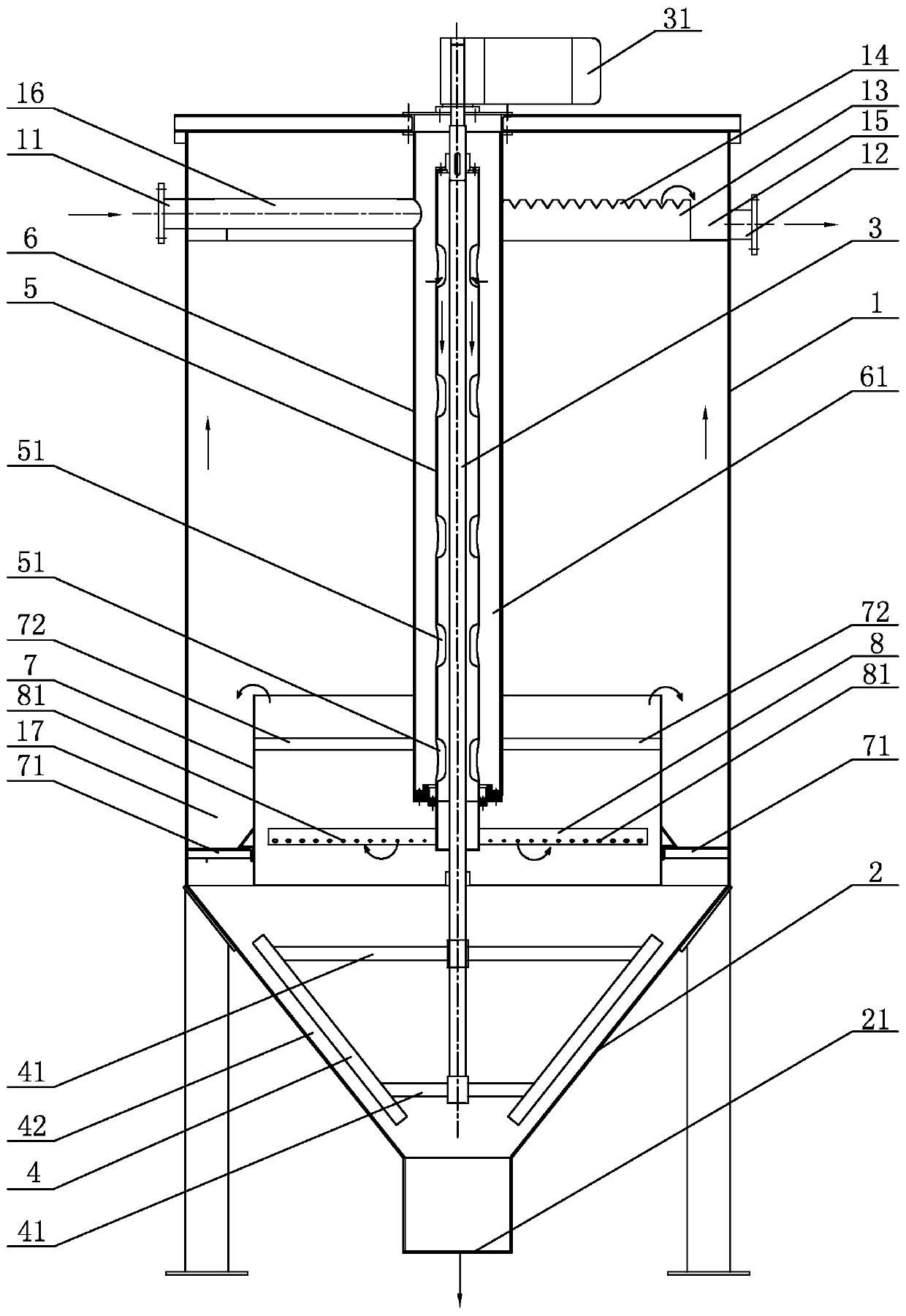

[0025] The improved vertical flow sedimentation tank of embodiment 1, as figure 1 As shown, the pool body 1 is included, the pool body 1 is provided with a water inlet 11 and a water outlet 12, the bottom of the pool body 1 is provided with a tapered mud bucket 2 with a large upper part and a smaller bottom part, and a mud scraping device is arranged in the pool body 1. The mud scraping device includes a driving device 31, a central transmission shaft 3 and a scraper, and the central transmission shaft 3 is connected to the output end of the driving device 31. In this embodiment, the driving device 31 adopts a motor, and the motor 31 is installed on the top of the pool body 1. The scraper is fixed on the central transmission shaft 3, and the scraper is located on the inner side of the mud bucket 2. The scraper includes a number of inclined plates 4, and the plurality of inclined plates 4 are fixedly connected with the central transmission shaft 3 through a plurality of connecti...

Embodiment 2

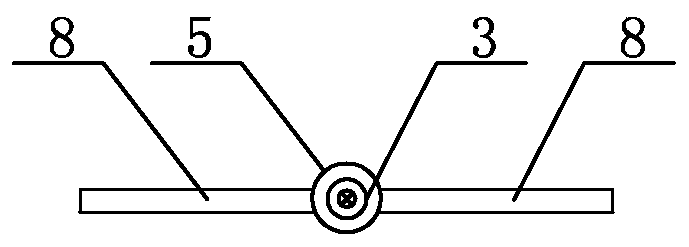

[0028] The difference between the improved vertical flow sedimentation tank of embodiment 2 and embodiment 1 is that in embodiment 2, the lower part of the central cylinder 5 communicates with a water distribution device, and the water distribution device is suspended in the mud turning box 7, using When, the sewage in the central cylinder 5 flows through the water distribution device and enters in the mud turning box 7.

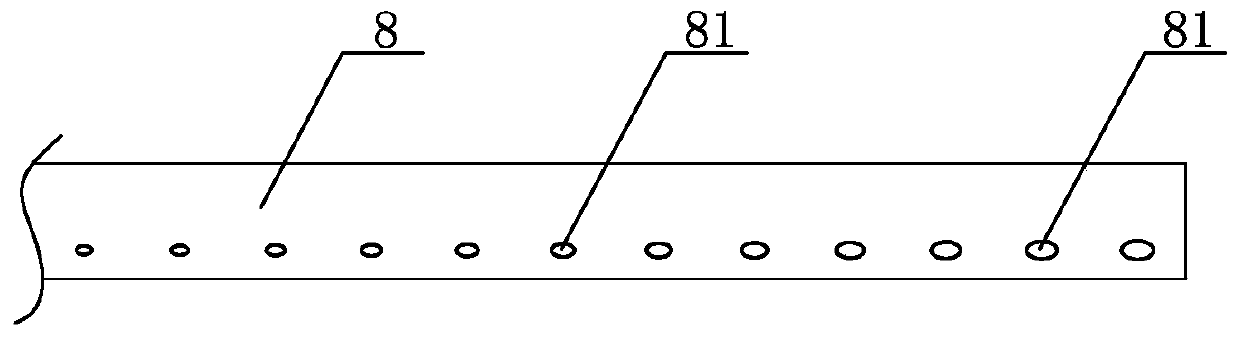

[0029] In Embodiment 2, the water distribution device includes an even number of water distribution pipes 8 arranged horizontally centered on the central transmission shaft 3, and each water distribution pipe 8 is provided with a plurality of water distribution holes 81, and the plurality of water distribution holes 81 are arranged along each The lengthwise direction of the water distribution pipe 8 is arranged at intervals; a plurality of water distribution holes 81 are provided at the bottom of each water distribution pipe 8, and the plurality of water dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com