Cremation machine tail gas spark blocking device and method

A technology of intercepting device and cremation machine, which is applied to chemical instruments and methods, separation methods, transportation and packaging, etc., can solve problems such as hidden safety hazards, loss, and influence on the effect of exhaust gas treatment, and achieve the effect of reducing dust removal efficiency and saving use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

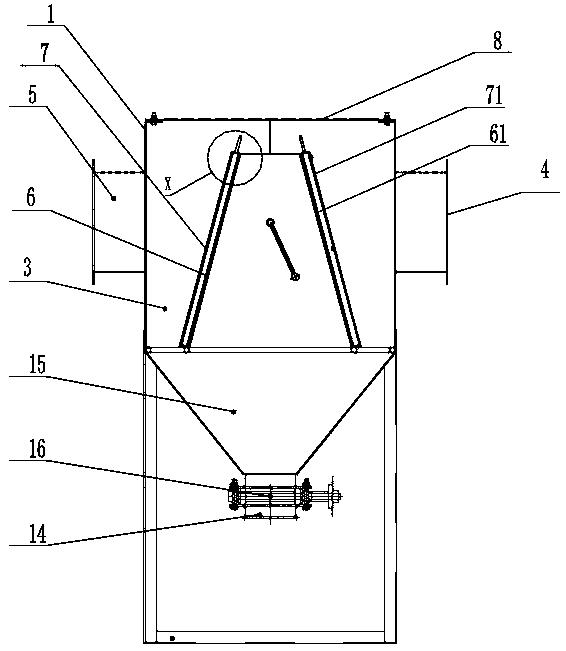

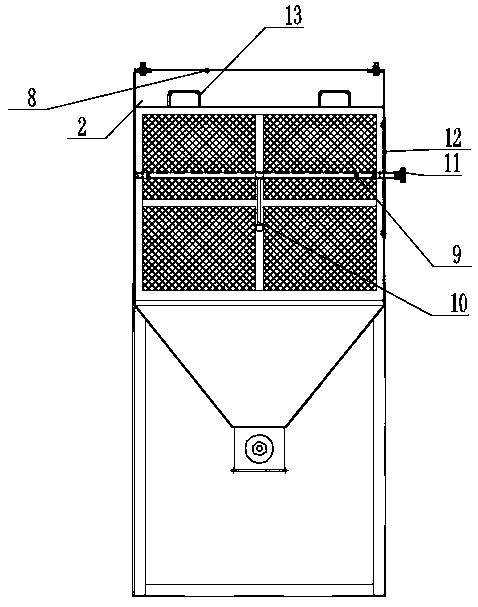

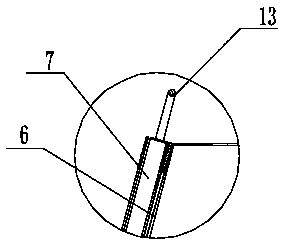

[0035] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

[0036] Such as Figure 1~Figure 3As shown, a spark intercepting device for cremation machine exhaust, the spark intercepting device includes an upper box 1, the air inlet 5 of the upper box 1 is sealed and connected with the air outlet 4 of the cremation machine exhaust, and the air outlet 4 of the upper box 1 is connected to the cremation machine. The air inlet 5 of the machine tail gas treatment system is sealed and connected. By setting in this way, the tail gas with sparks generated by the combustion of the cremator can be filtered through the spark interception device first, and then from the air outlet 4 of the upper box 1 and the tail gas treatment device. The air inlet 5 is connected, and the upper box body 1 includes a left side panel 2, a right side panel, a front side panel 3 and a rear side panel, the left side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com