Cup wall overflow type constant volume cup

An overflow type, constant volume cup technology, applied in the field of experimental instruments, can solve the problems of increased solution splashing, unclean washing, inconvenient transfer and constant volume operation, and increased operating steps, so as to reduce errors and reduce visual errors , The effect of simplifying the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

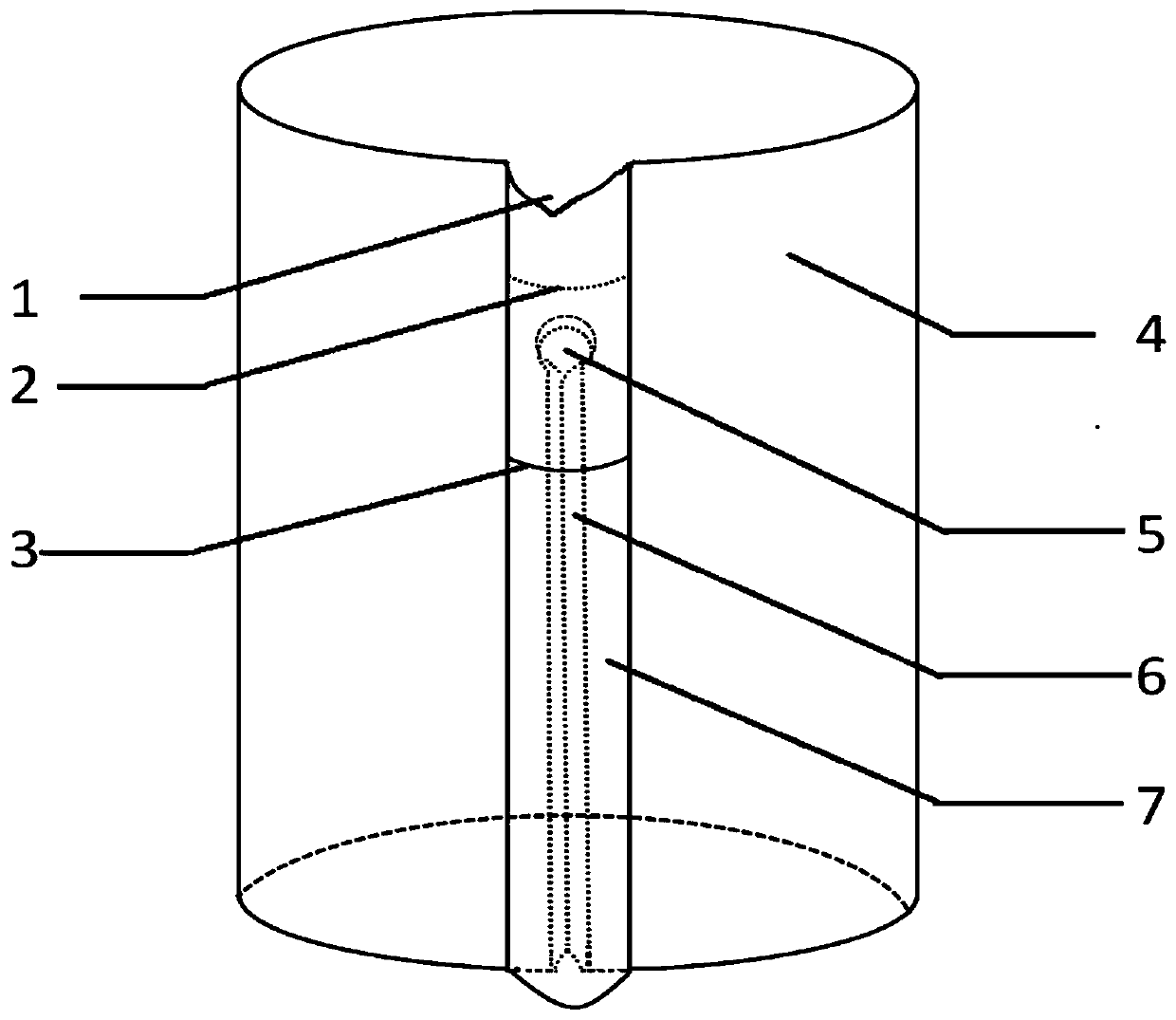

[0018] Such as figure 1 Shown, the present invention uses a beaker 4 as a dissolving cup for dissolving solute and carrying solution, and an overflow hole 5 is obliquely downward 45° from the inside to the outside on the top of the beaker 4 back, and the overflow hole 5 lower end is a sharp mouth shape, which is easy to The liquid flows out, goes down along the overflow hole 5, and opens a long and thin diversion groove 6 from top to bottom on the outer wall of the beaker 4, and uses a semi-cylindrical constant volume tube on the periphery of the overflow hole 5 and the diversion groove 6 5 is in close contact with the outer wall of the beaker 4, and the beaker 4 and the constant volume tube 7 communicate with each other through the overflow hole 5 and the diversion groove 6. A larger gap is opened on the outer wall of the beaker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com