Vertical construction method and apparatus for architectural reinforcing bar groups

A construction method and a technology of building steel bars, which are applied in the direction of buildings, building components, building reinforcements, etc., can solve problems such as waste of time and construction period, waste of manpower, water penetration, and shortcomings of electrical pipeline construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

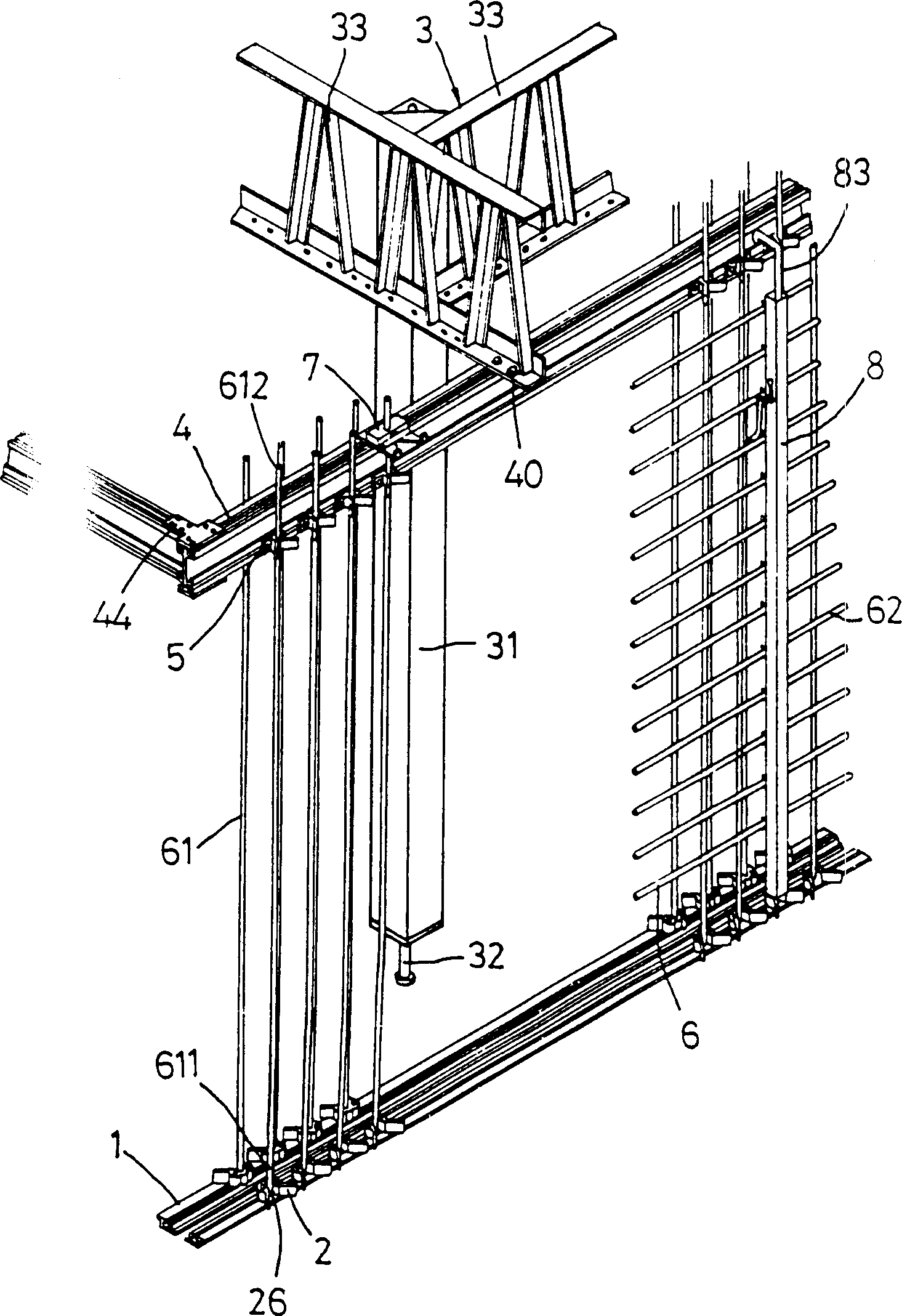

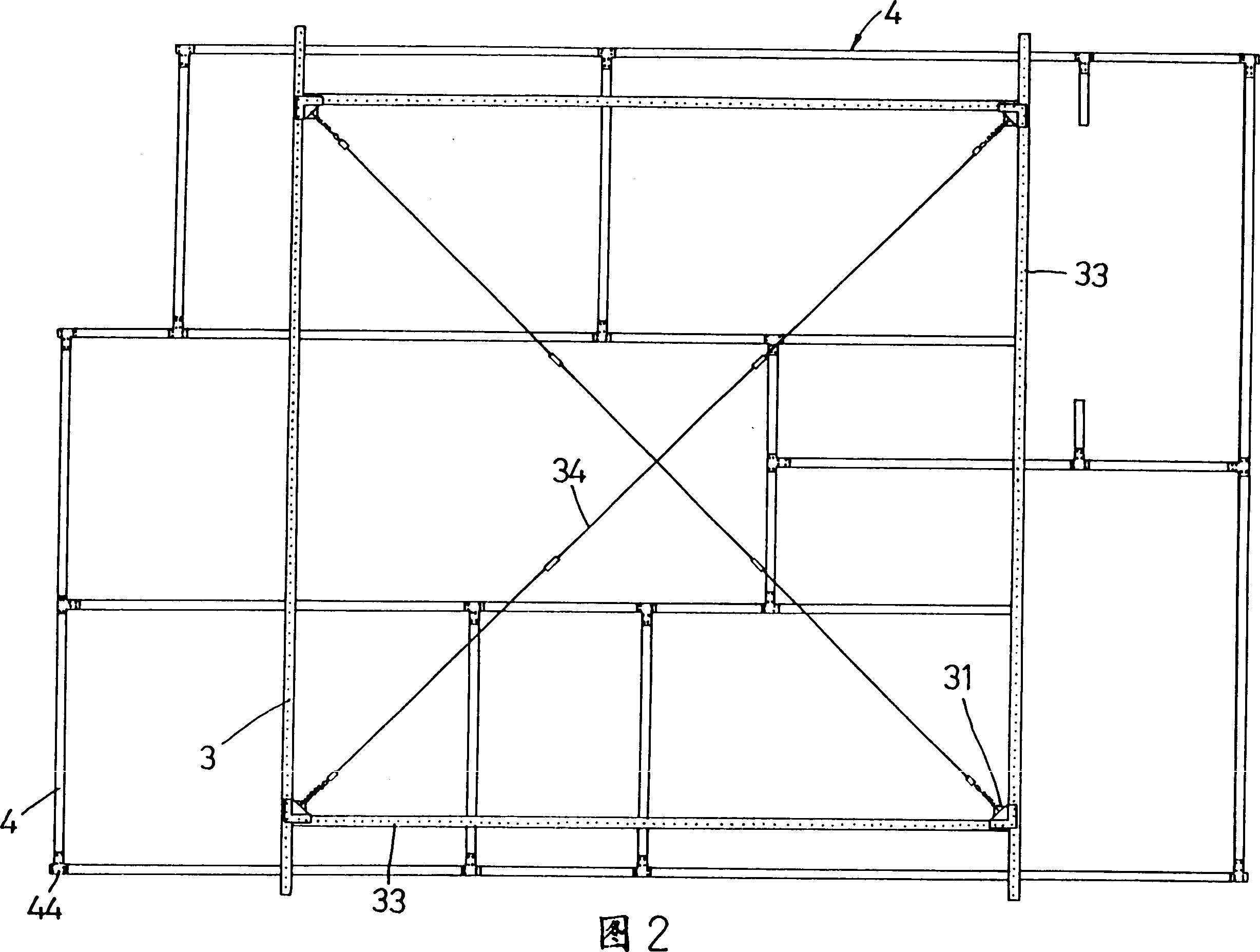

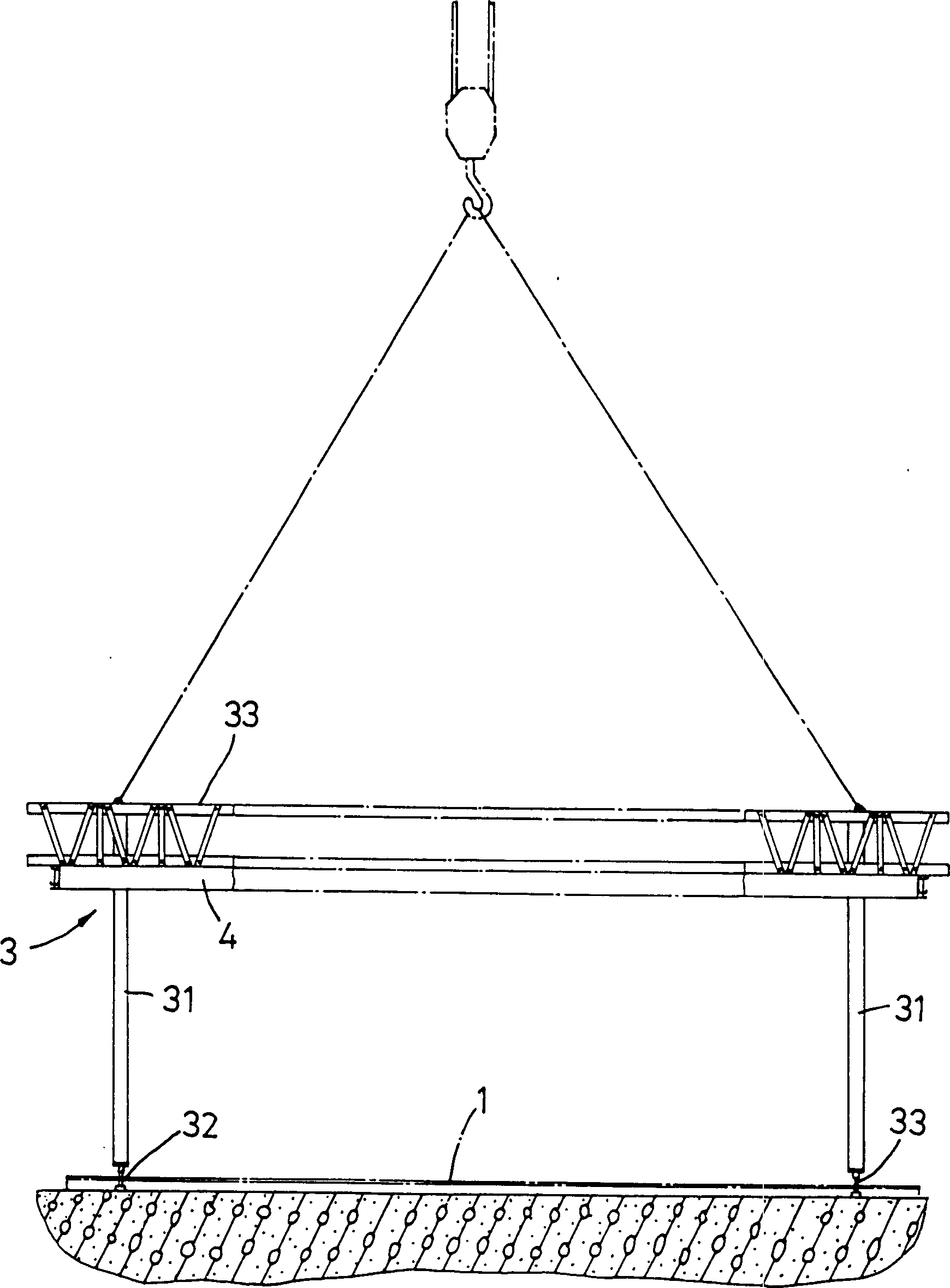

[0027] Such as figure 1 , Figure 2 and image 3 As shown, the building reinforcement construction method of the present invention is set up as an example in this embodiment. The wall reinforcement can be set up offline in advance in the open space next to the building floor, and the wall reinforcement after the establishment can be lifted. It is moved to the position where the floor slab of the building floor should be installed, and the building reinforcement installation includes a lower fixing seat 1, several lower positioning blocks 2, a main frame 3, an upper fixing seat 4, several upper positioning blocks 5, and several steel bars. 6. A number of clamping components 7 and a number of horizontal rib placement racks 8 .

[0028] see Figure 4 , Figure 5 As shown, the lower fixing seat 1 is fixed on the pre-determined open space next to the building to simulate the lofting line on the wall on the entire floor, and the lower fixing seat 1 is fixed on the buried in the bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com