Spline broach with broaching stress release area and correction area

A technology of stress relief and spline broaching, which is applied in broaching tools, broaching machines, metal processing equipment, etc., can solve problems such as parts deformation, and achieve the effects of improved broaching efficiency, less control links, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention but not to limit the scope of the present invention.

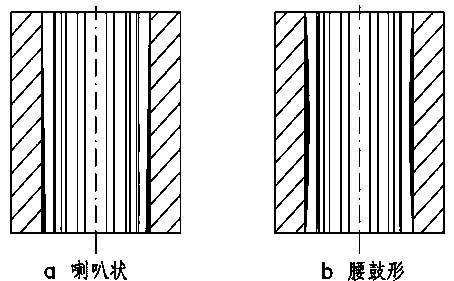

[0022] use figure 1 The traditional spline broach processing, the parts are deformed after drawing, such as figure 2 shown.

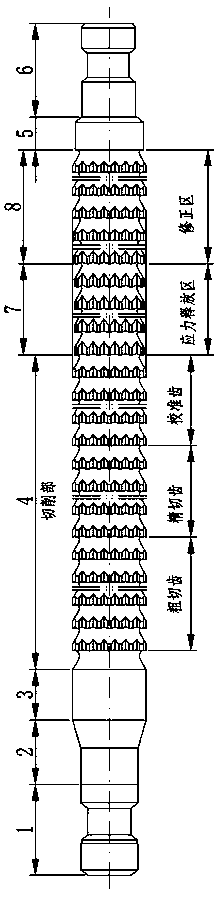

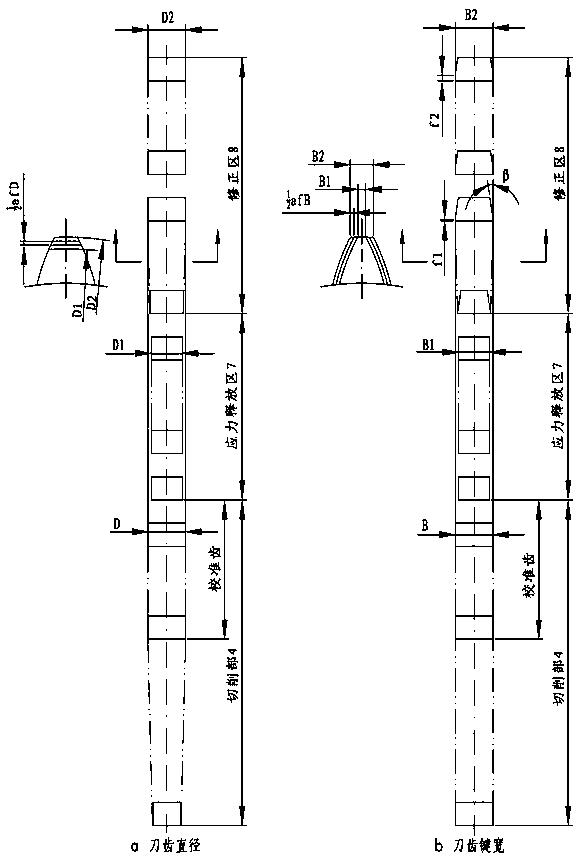

[0023] use image 3 The present invention is a spline broach with a broaching stress release zone and a correction zone. When the part passes through the stress release zone 7 and the correction zone 8 respectively, the stress release zone 7 in the front section gives the part sufficient deformation release space, and the rear part The first-stage correction zone 8 fully corrects the size and shape of the part, so that it can be formed by one-time broaching. Compared with the parts that have survived through one or two-step broaching, the precision is h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com