Cutting and crushing device for junked tires

A technology for cutting and crushing waste tires, applied in recycling technology, mechanical material recycling, plastic recycling, etc., can solve the problems of flying out of tire scraps, cleaning of grinding wheels, affecting the cutting effect of tires, etc. Screening rate, the effect of improving the efficiency of crushing and recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

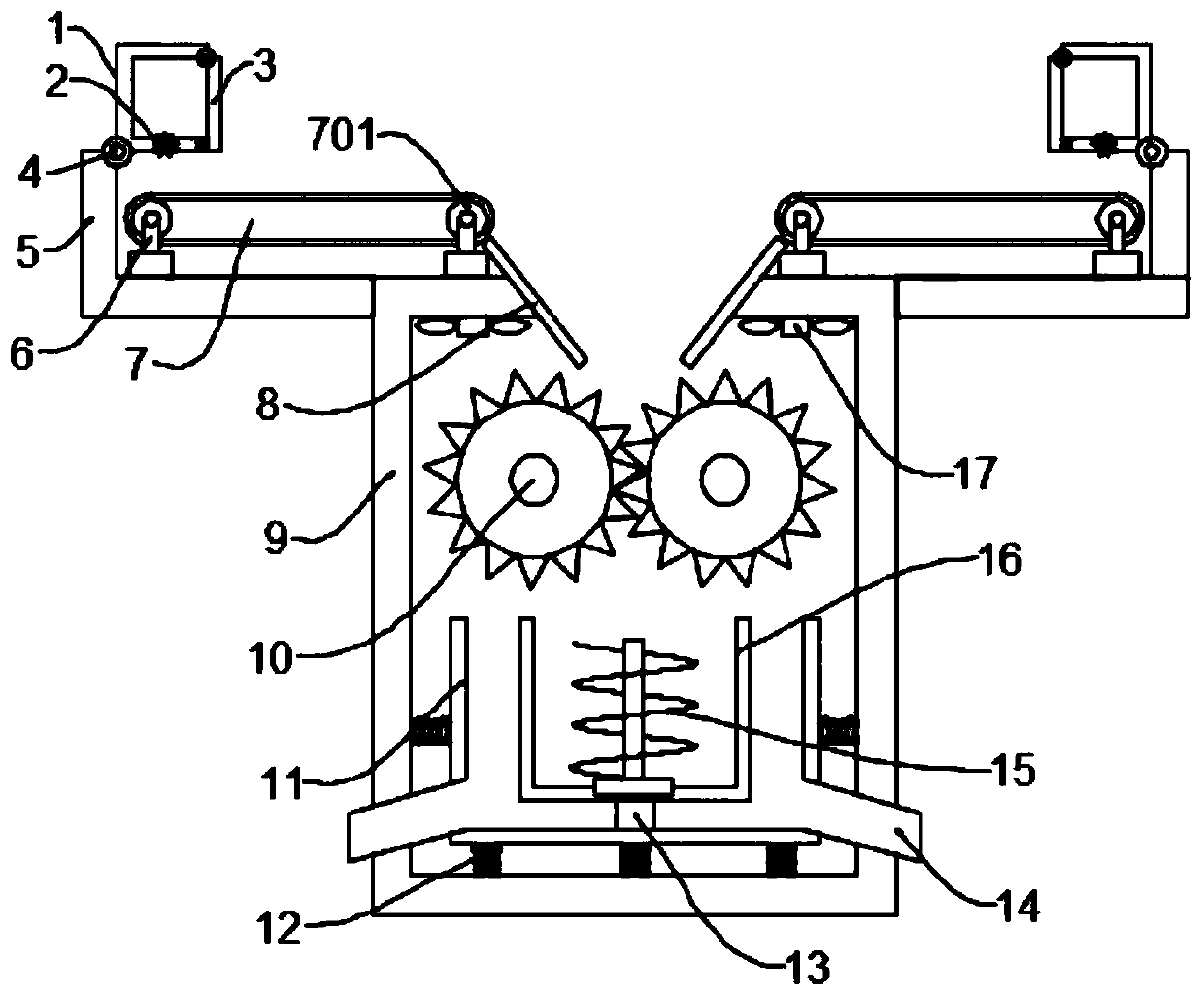

[0020] see Figures 1 to 3 :

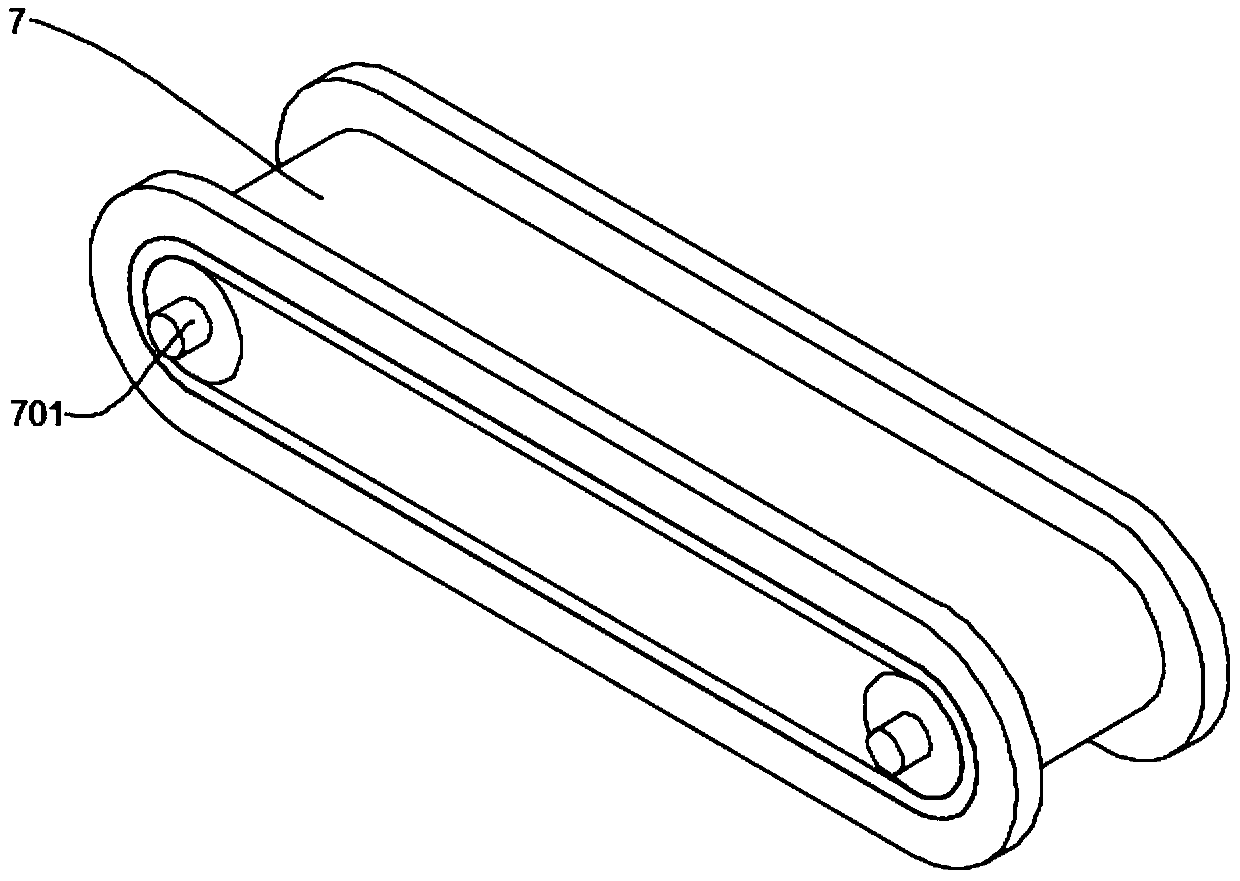

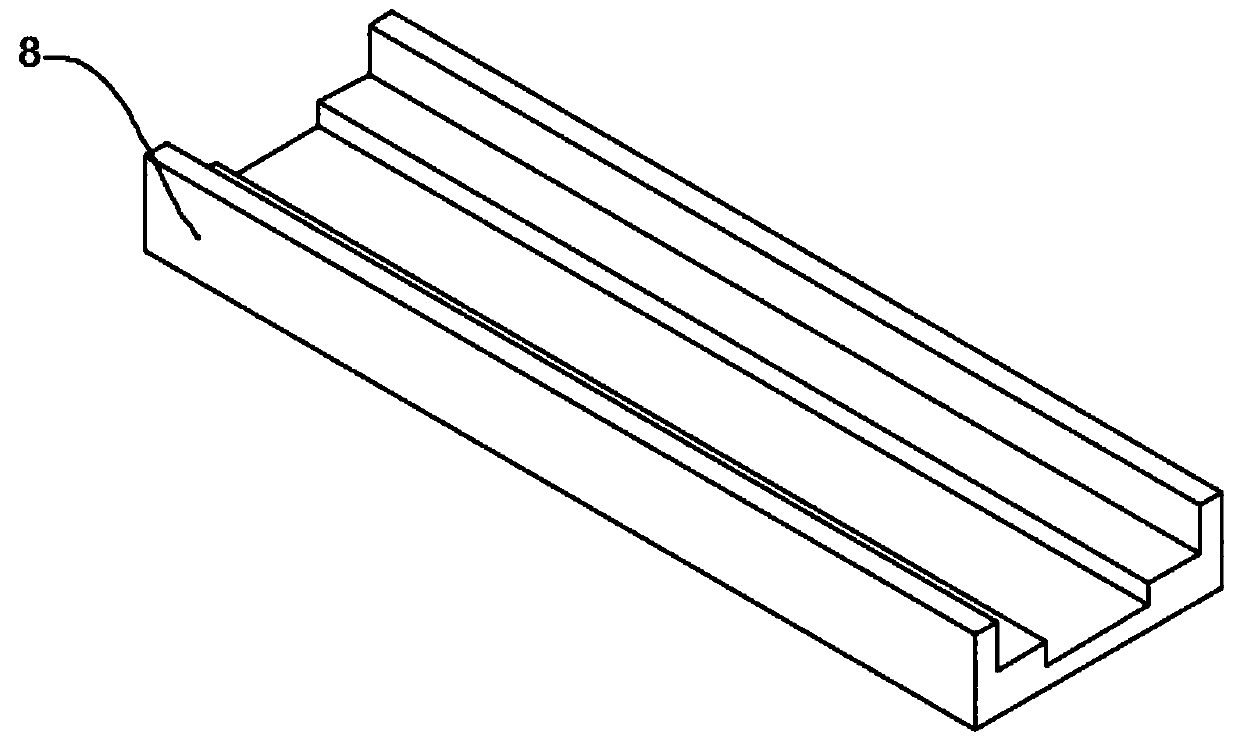

[0021] This embodiment provides a further preferred solution for a waste tire cutting and crushing device, which includes a feeding chamber 1 and a crushing chamber 9. A cutting machine 3 is movably connected to the bottom of the inside of the feeding chamber 1, and a movable plate 3 is movably connected to the upper right side of the outside of the feeding chamber 1. The feeding chamber 1 is fixedly provided with a support plate 5 on the outside, a conveyor belt 7 is fixedly connected above the support plate 5, a motor 701 is movably connected to both ends of the inner side of the conveyor belt 7, a base 6 is fixedly connected to the bottom of the motor 701, and both sides of the top opening of the crushing chamber 9 are fixed. A guide plate 8 is connected, and a crushing wheel 10 is movably connected to the bottom of the guide plate 8. A storage barrel 11 is fixedly arranged below the crushing wheel 10. A turntable 13 is embedded in the inner b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com