Plastic crusher

A technology of plastic crusher and crushing box, which is applied in the direction of plastic recycling, mechanical material recycling, recycling technology, etc., and can solve the problems of low crushing efficiency, low crushing and recycling efficiency, and missed cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

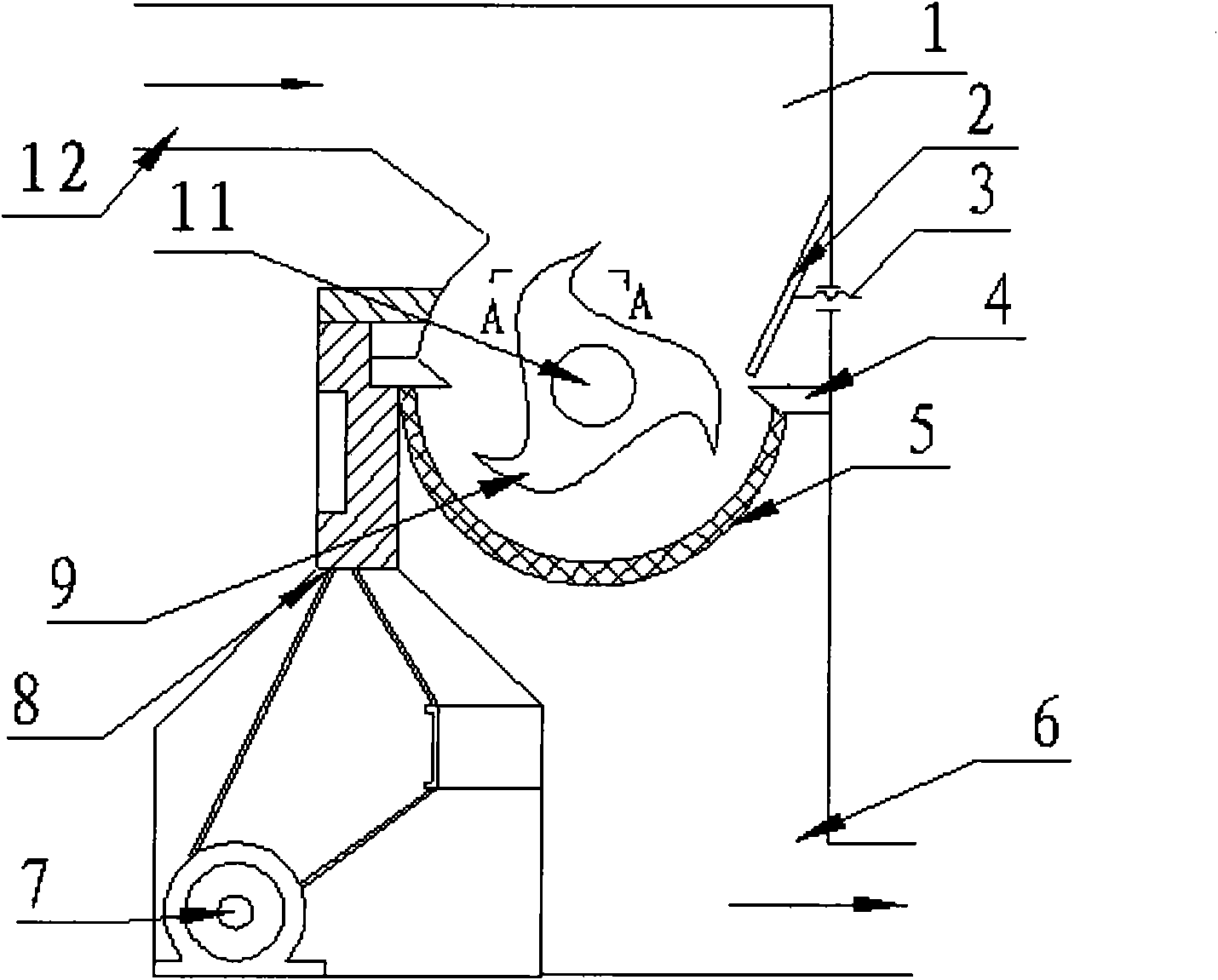

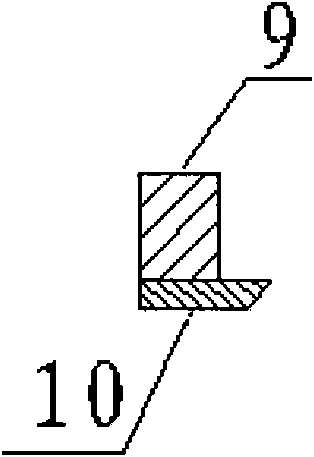

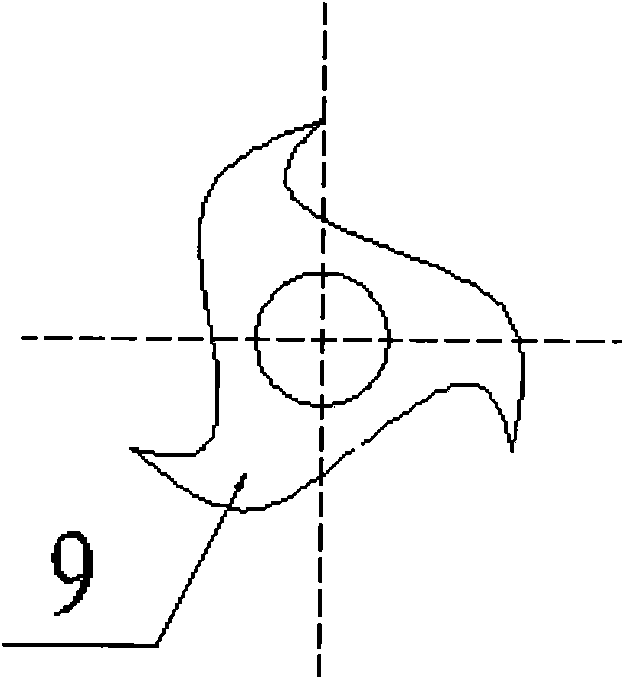

[0015] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the plastic crusher includes a crushing box 1, a combined knife, a main shaft 11, a fixed knife 4, a sieve plate 5, a motor 7, and a pulley 8. The crushing box 1 is a semi-cylindrical box, and the feeding port 12 is located at the top of the crushing box 1. , the discharge port 6 is located below the crushing box 1, the sieve plate 5 is semi-circular, and is fixedly connected to the lower part of the box. The planar shape of blade 10 is basically the same as that of the rotary blade, only protruding slightly at the cutting edge. 10 is detachably connected with the main shaft 11. Have bearing hole on the two end faces of casing, the main shaft 11 that is fixed with combination knife is installed in two bearing holes by bearing, and one end of main shaft 11 is designed with belt pulley 8, is connected with motor 7 by belt. There is a fixed knife 4 on the box seat in the box, and a movable adjustment baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com