Conveying and arranging mechanism of bag arranging machine

A technology of sorting mechanism and bag management, applied in the directions of transportation and packaging, automatic control of packaging, packaging, etc., can solve the problems of inconvenient adjustment, deflection or even overturning of packaging bags, influence of subsequent processes, etc., which is beneficial to the bundling process and saves Reliable and effective effect of time and manpower, structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

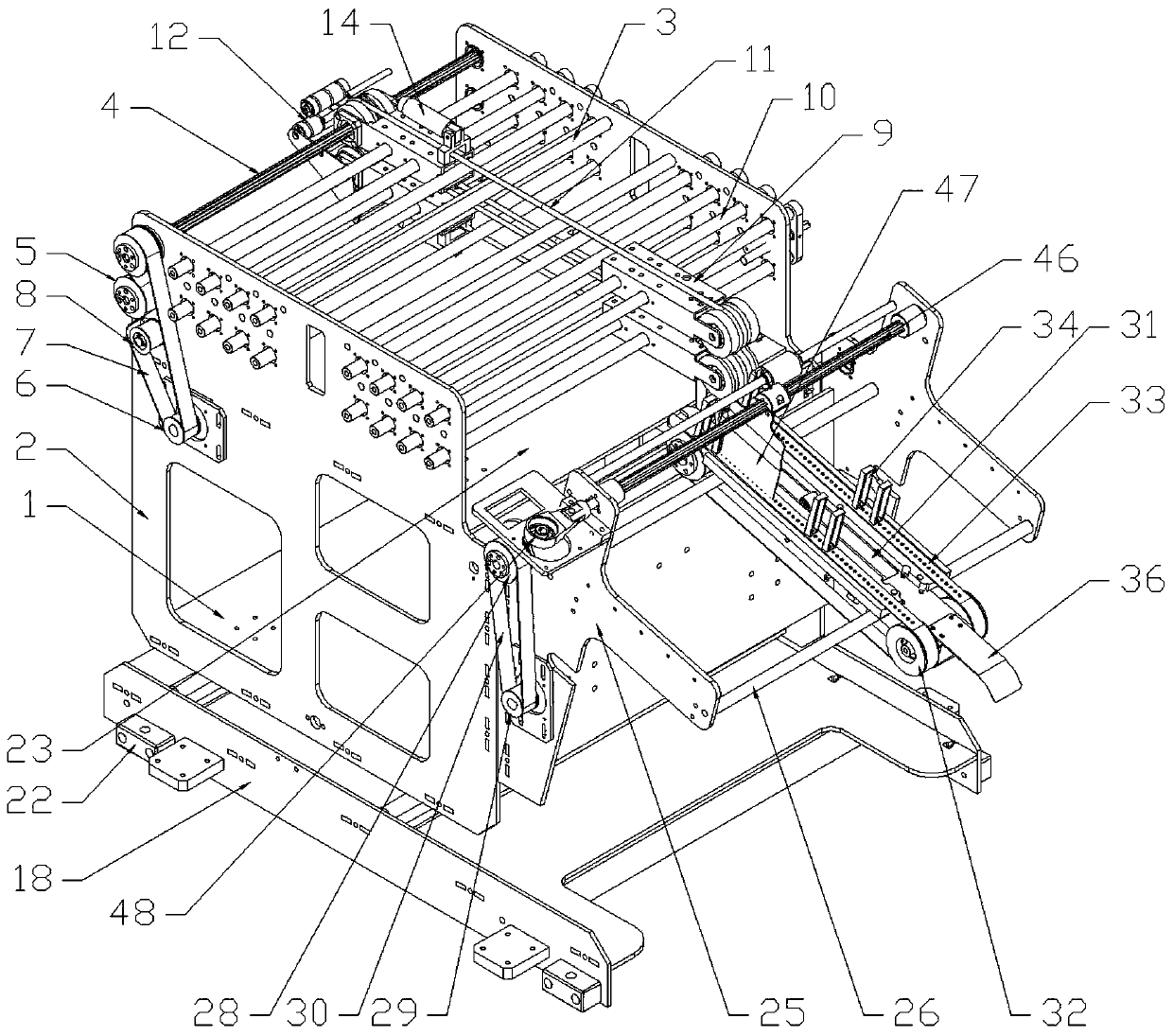

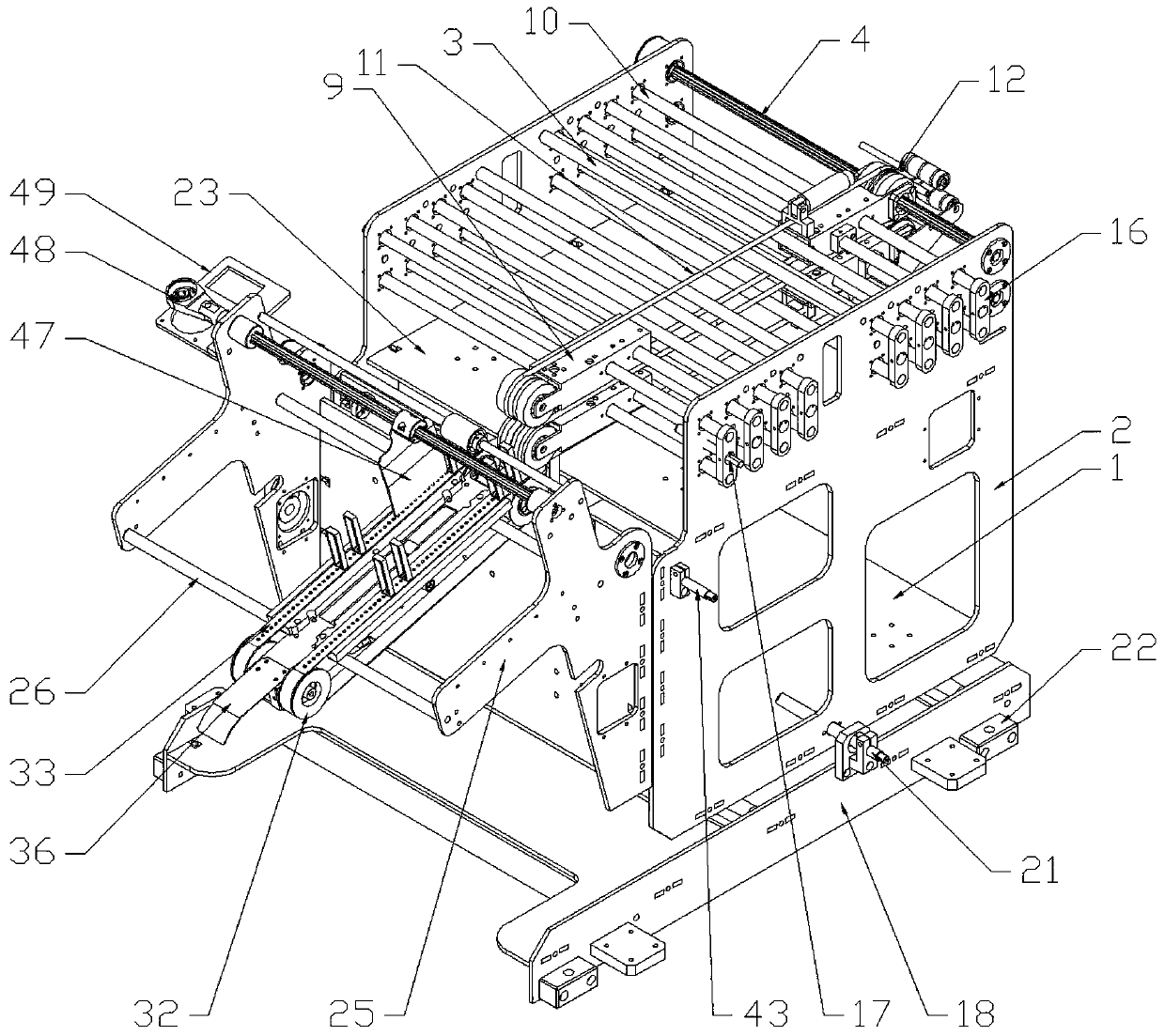

[0055] Embodiment one: if Figure 1-8 As shown, a conveying and sorting mechanism of a bag unscrambling machine is used for sorting and transporting packaging bags, including two parallel sorting wall panels 25, which are supported by a certain number of optical axes a26 between the sorting wall panels. The front end frame of the wallboard 25 is provided with a drive shaft a27, and one end of the drive shaft a27 is connected with a synchronous pulley a28. connect. combine Figure 9-11 As shown, at least one finishing and conveying assembly is provided between two finishing wallboards 25, and the finishing and conveying assembly includes an aluminum tube beam 31, and at least two installation holes a31.1 are arranged on the aluminum tube beam 31, and the aluminum tube beam 31 The front is high and the rear is low on the optical axis a26. The two sides of the front and rear ends of the aluminum tube beam 31 are respectively equipped with synchronous conveying wheels 32. The fr...

Embodiment 2

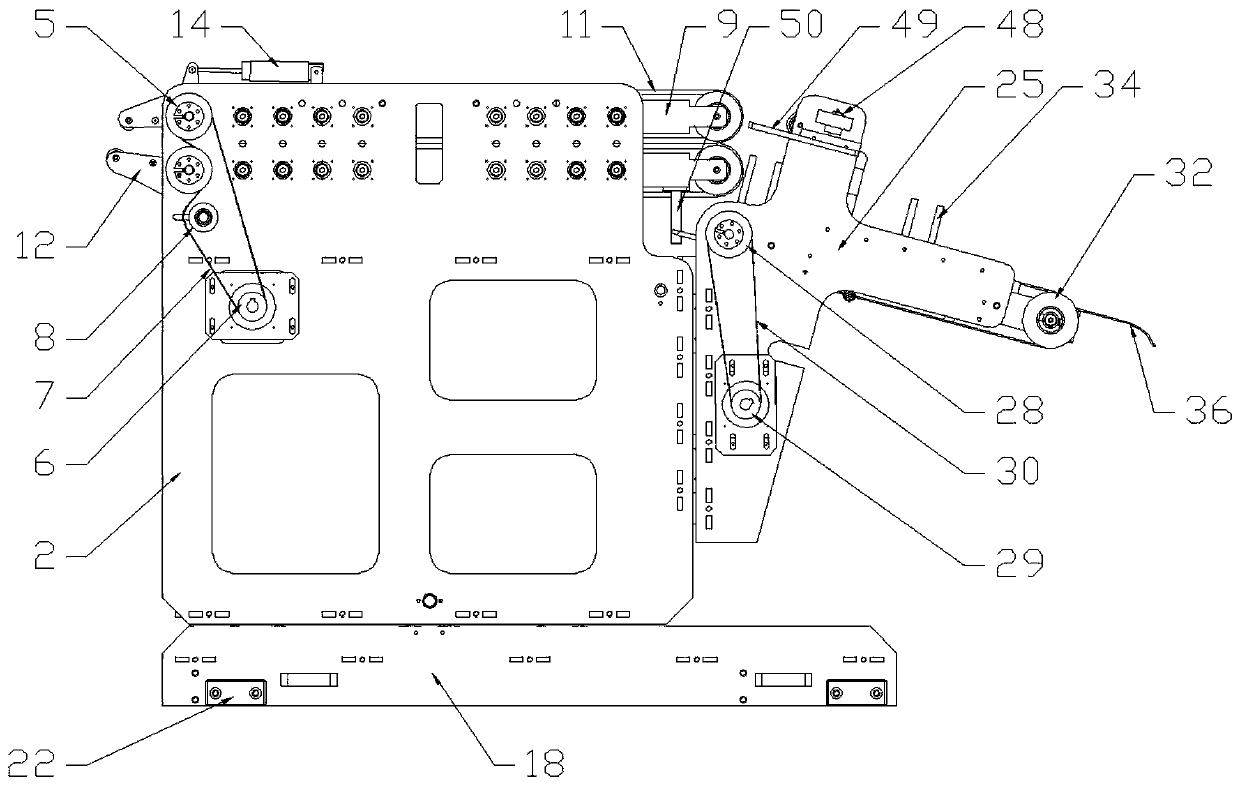

[0057] Embodiment 2: Combination Figure 4-8 As shown, on the basis of Embodiment 1, a vertical first baffle 38 is arranged at the front end of the finishing wall panel 25, a vertical second baffle 39 is arranged on the front side of the first baffle 38, and a vertical second baffle 39 is arranged on the rear side of the second baffle 39. The side is provided with at least two vertical linear guide rails a40, the front side of the first baffle plate 38 is provided with several sliders a41, the middle of the second baffle plate 39 is provided with an opening 39.1, and the second baffle plate 39 front side at the opening 39.1 A vertical adjusting screw a42 is provided, and a horizontal operating rod 43 is also provided on the front side of the second baffle plate 39. The ends of the adjusting screw a42 and the operating rod 43 are provided with mutually meshing bevel gears 44, and the adjusting screw A42 is provided with a nut 45, and the nut 45 passes through the opening 39.1 a...

Embodiment 3

[0058] Example Three: Combining Figure 1-3 As shown in and 12-17, on the basis of Embodiment 2, a conveying mechanism is arranged on the front side of the finishing wallboard 25, and the conveying mechanism includes a bottom plate 1 and conveying wallboards 2 on both sides, and a certain amount of light passes between the conveying wallboards 2. Supported by the shaft b3, the second baffle 39 is fixed on the rear end of the conveying wallboard 2. The front end of the conveying wallboard 2 is provided with two parallel transmission shafts b4 up and down. The transmission shaft b4 can be a spline shaft, and one end of the transmission shaft b4 is connected There is a synchronous belt pulley b5, and a driving wheel b6 connected to the motor is fixed on the conveying wallboard 2. The synchronous belt wheel b5 and the driving wheel b6 are connected through a synchronous belt b7 and the synchronous belt b7 is connected to the two synchronous pulleys b5 in reverse. Wherein, a tensio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com