Automatic sludge biogas production device

A biogas device and automatic production technology, applied in biological sludge treatment and other directions, can solve the problems of inability to realize automatic liquid discharge and liquid inflow, reduce the production of biogas, and reduce the utilization rate of sludge, so as to avoid the low production of biogas. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

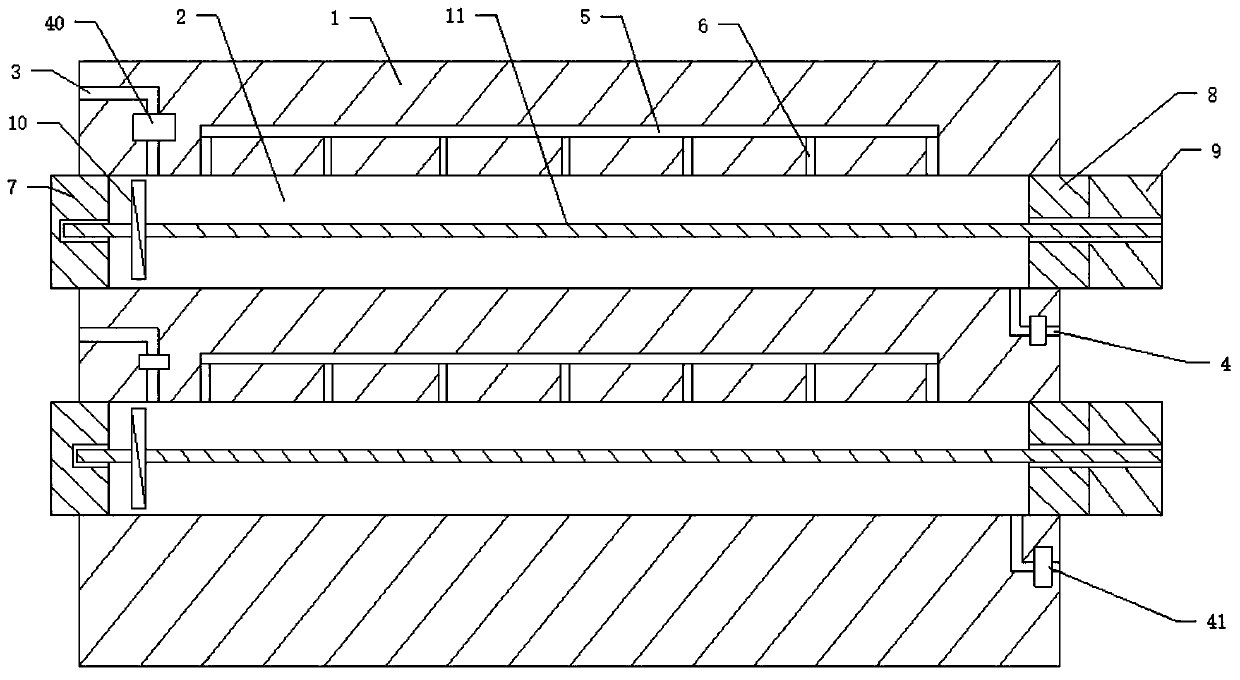

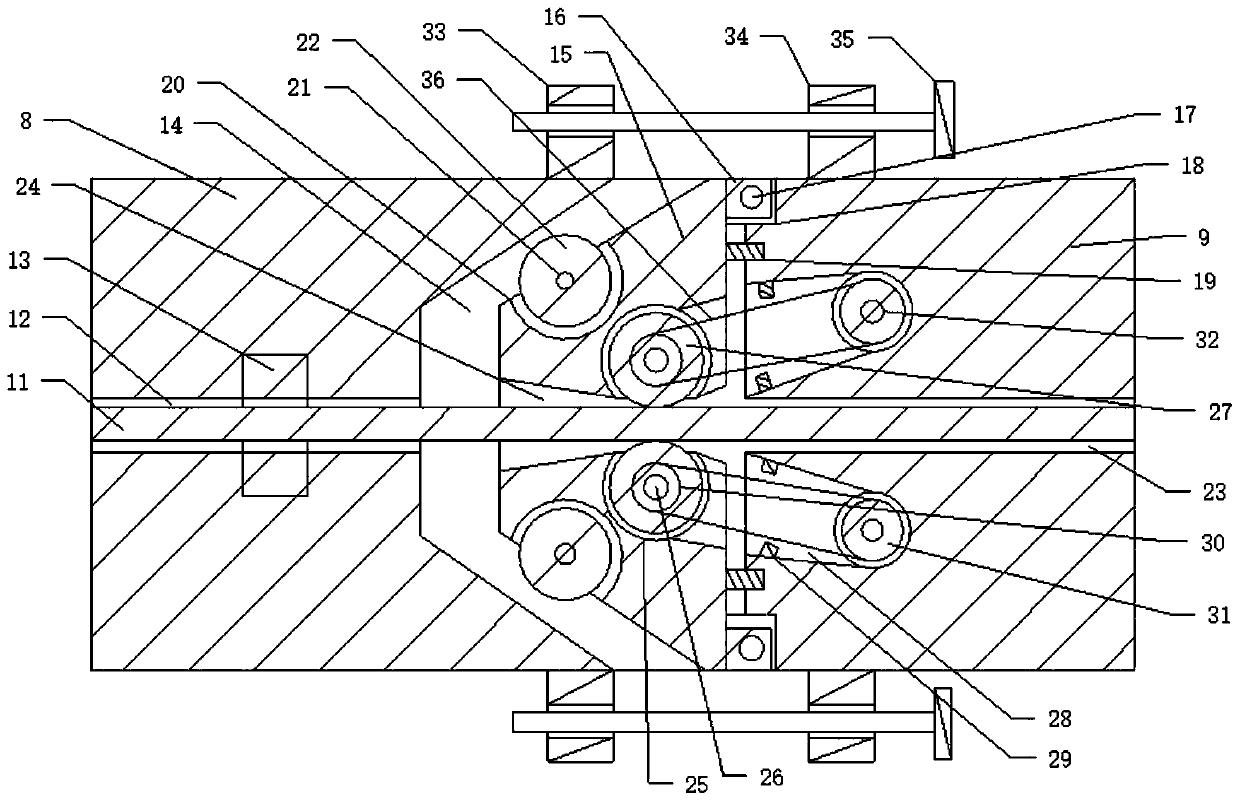

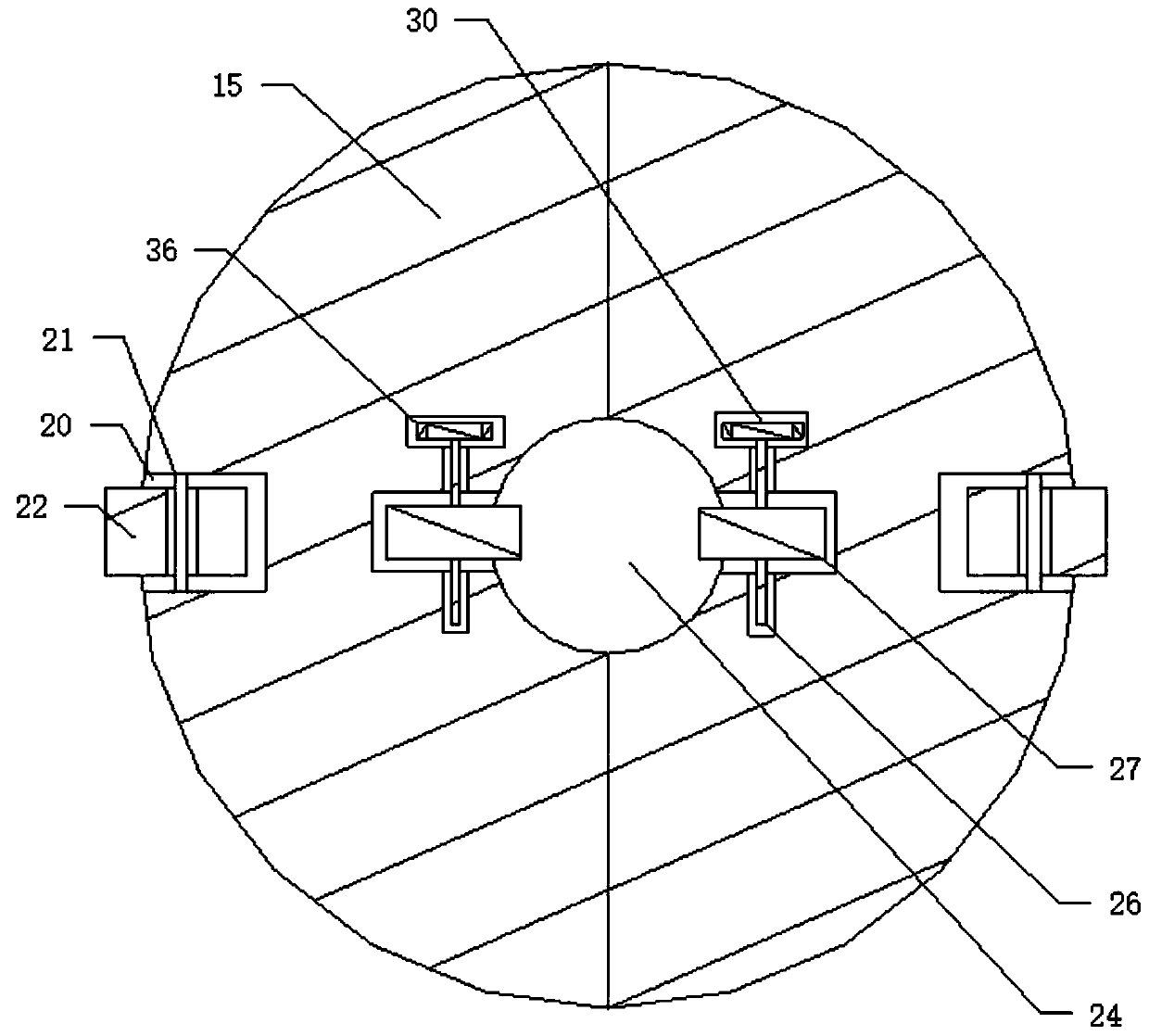

[0033] Such as Figure 1 to Figure 7 As shown, a sludge automatic biogas production device includes a body 1, and the body 1 is provided with a plurality of biogas inner cavities 2, and one end of the biogas inner cavity 2 is respectively provided with a first end 7, The other end of the biogas inner cavity 2 is respectively provided with a second end 8, and a sliding pull rod 11 is respectively arranged in the biogas inner cavity 2, and a sealing push plate 10 is respectively arranged at the end of the pull rod 11 , the sealing push plate 10 and the biogas inner chamber 2 are in a sealed connection, and the second ends 8 are respectively provided with a power end 9, and the power ends 9 respectively control the sliding of the pull rods 11.

[0034] A plurality of biogas inner cavities 2 are provided on the body 1, and the number of biogas inner cavities 2 can be set according to the needs of the design. The biogas inner cavity 2 is a cavity, and one end of the biogas inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com