A high-end passenger ferry steel with a thickness of less than 12mm and its manufacturing method

A high-end, ferry technology, applied in the high-end passenger ferry steel and its manufacturing field, can solve the problems of small loading tonnage and load area, not suitable for large-scale and heavy-duty ferry requirements, and achieve stable and improved production process. Inclusion morphology, fine grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

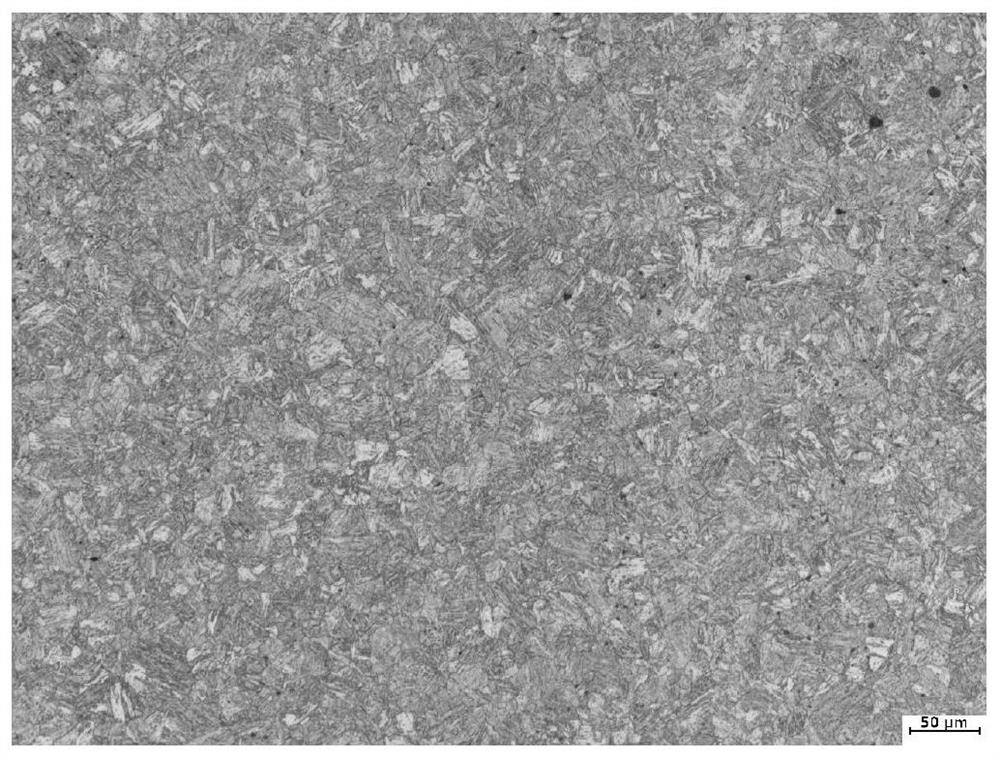

Image

Examples

Embodiment 1

[0046] The production method of Example 1 is as follows: steelmaking and continuous casting: S: 0.003% after desulfurization of molten iron; converter smelting adopts high-blowing and low-drawing method for dephosphorization, and converter tapping slag; refining adopts white slag operation, and the white slag retention time is 13mmin , the total refining time is 30min; the vacuum degree is 3.0mbar, and the treatment retention time is 20min. After the vacuum treatment, the seamless calcium line treatment is carried out, and the static stirring time is 12min; / min;

[0047] Rolling: Heating temperature before rolling is 1280°C, billet thickness is 150mm, total heating time is 165min, rolling temperature is 1200°C, rolling passes are 9 passes, air cooling is carried out after rolling, hot straightening is carried out for 3 passes, hot straightening temperature is 700°C, warm straightening 1 pass, temperature correction temperature 380 ℃;

[0048] Heat treatment: quenching temper...

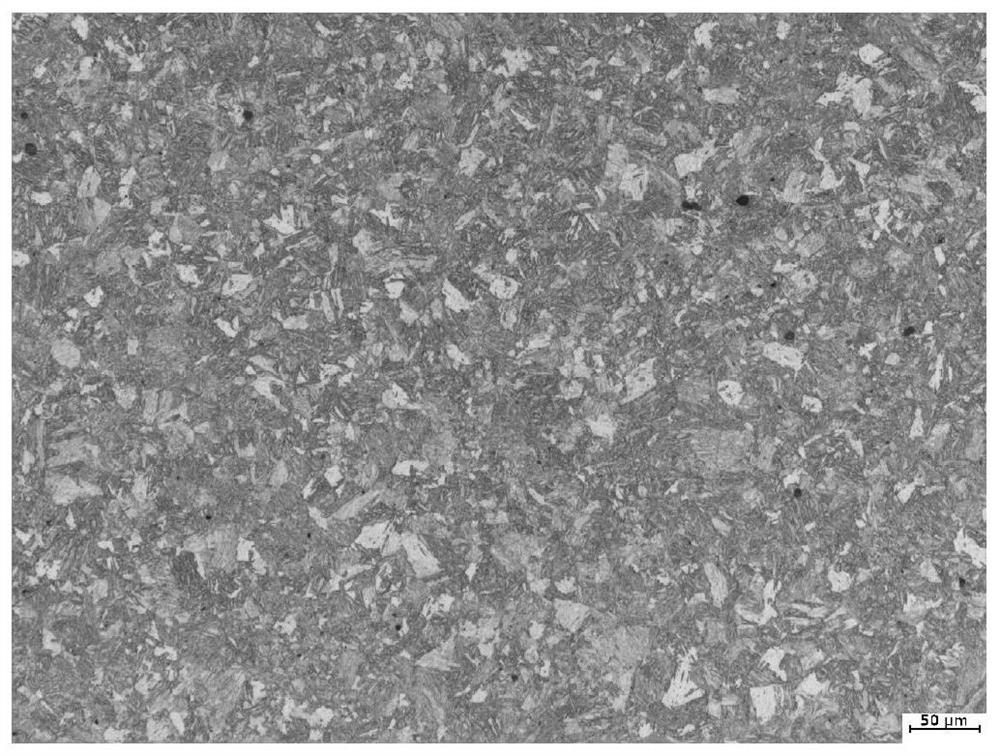

Embodiment 2

[0049] The production method of embodiment 2 is as follows:

[0050] Steelmaking and continuous casting: S: 0.0025% after molten iron desulfurization; converter smelting adopts double slag method for dephosphorization, converter taps steel to block slag; refining adopts white slag operation, white slag retention time 15mmin, total refining time 33min; vacuum degree 3.0mbar , the treatment holding time is 20 minutes, the seamless calcium line treatment is carried out after the vacuum treatment, and the static stirring time is 13 minutes; the target temperature of the continuous casting tundish is the liquidus temperature +10°C, and the casting speed is 0.8m / min;

[0051] Rolling: Heating temperature before rolling is 1250°C, billet thickness is 150mm, total heating time is 150min, rolling temperature is 1180°C, rolling passes are 7 passes, air cooling is carried out after rolling, hot straightening is carried out 2 passes, hot straightening temperature is 800°C, warm straighteni...

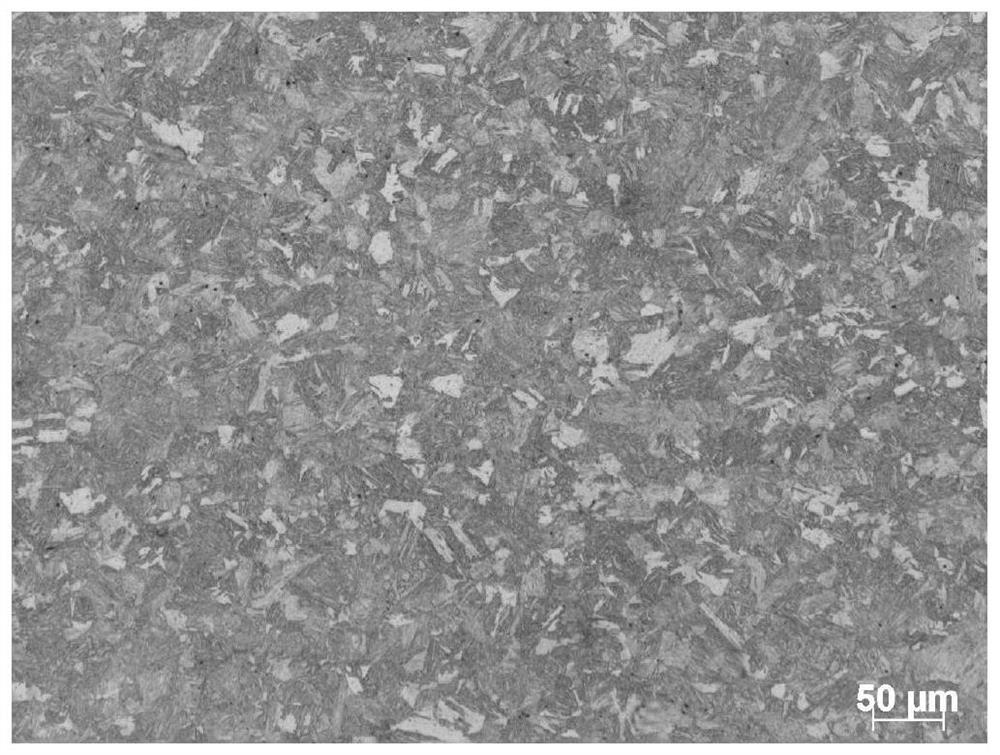

Embodiment 3

[0053] The production method of embodiment 3 is as follows::

[0054] Steelmaking and continuous casting: S: 0.0030% after molten iron desulfurization; converter smelting adopts double slag method for dephosphorization, converter tapping to block slag; refining adopts white slag operation, white slag retention time 14mmin, total refining time 40min; vacuum degree 3.0mbar , The treatment holding time is 21 minutes, the seamless calcium line treatment is carried out after the vacuum treatment, and the static stirring time is 13 minutes; the target temperature of the continuous casting tundish is the liquidus temperature + 5°C, and the casting speed is 0.9m / min;

[0055] Rolling: Heating temperature before rolling is 1230°C, billet thickness is 150mm, total heating time is 135min, rolling temperature is 1180°C, rolling passes are 7 passes, air cooling is carried out after rolling, hot straightening is done once, hot straightening temperature is 850°C, warm straightening 3 passes,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com