A circuit board electroplating liquid intelligent filtration system without changing filter elements and its application method

A filter system and electroplating solution technology, which is applied in the electrolysis process, electrolysis components, cells, etc., can solve the problems of affecting the quality and appearance of PCB products, the bath solution cannot be effectively filtered, and the waste of electroplating solution and water sources, etc., to achieve reduction and no consumables cost, ensure filtration efficiency and cleaning effect, and save the production cost of the enterprise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

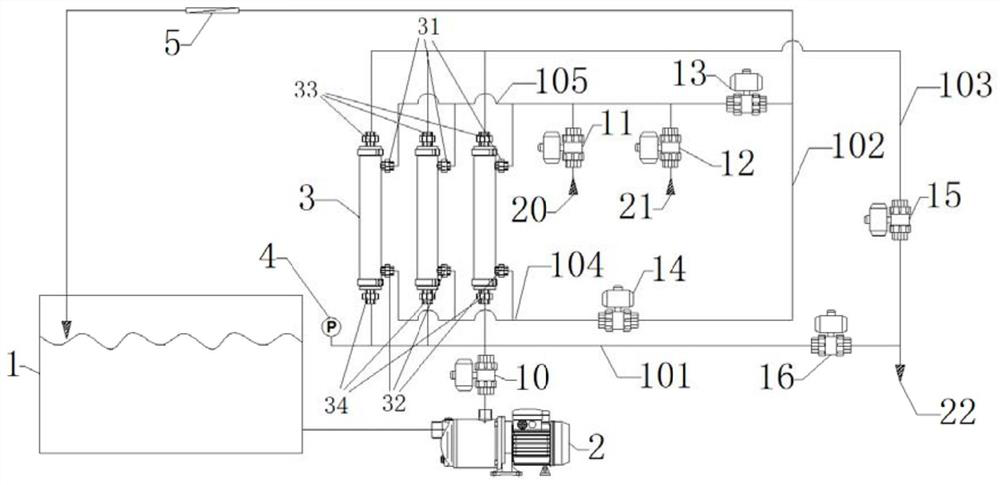

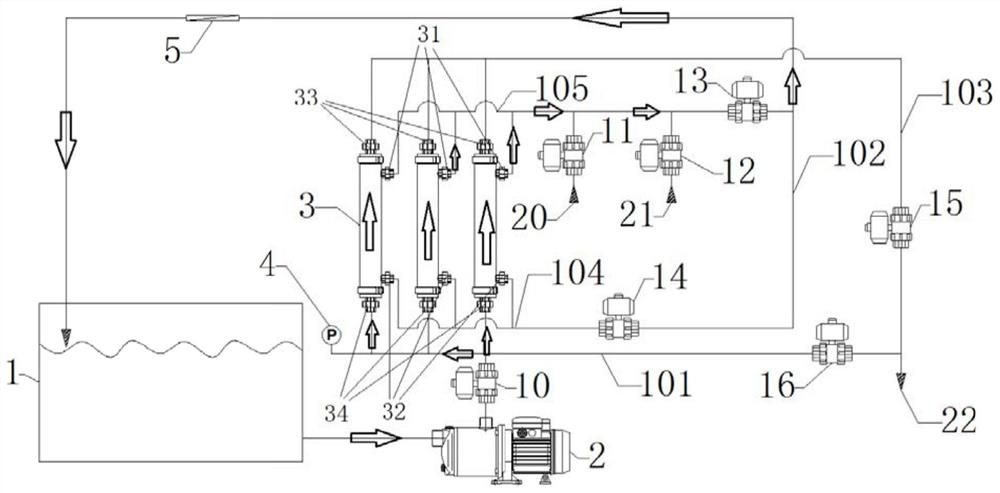

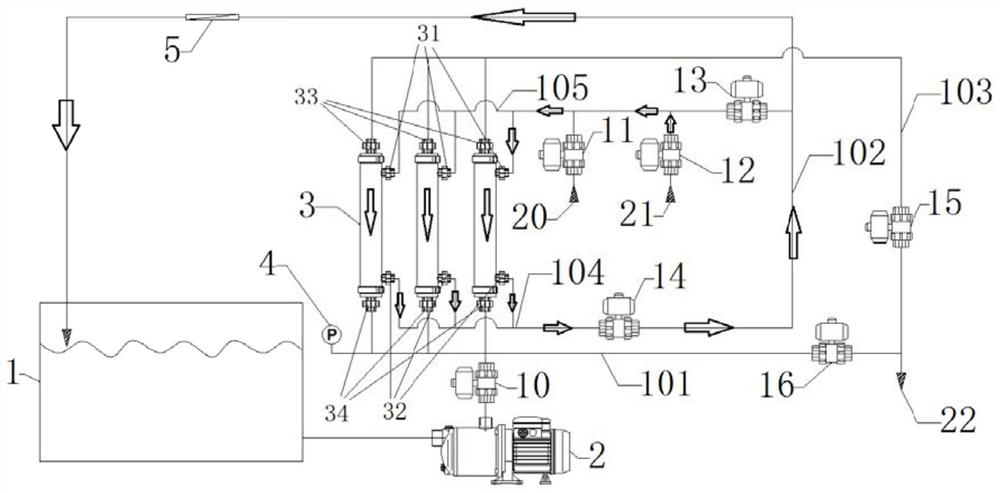

[0040] refer to Figure 2 to Figure 3d As shown, the circuit board electroplating liquid intelligent filtration system of a kind of free filter element of the present invention adopts two kinds of purification modes, and the purification modes are divided into intelligent filtration mode and intelligent cleaning mode:

[0041] Smart Filtration Mode uses the following steps to purify the plating solution:

[0042] S1, open the water inlet valve 10 and the first water production valve 13 and close other valves;

[0043] S2, open the filter pump 2, so that the electroplating solution enters the inside of the precision filter module 3 through the filter pump 2, the water inlet valve 10 and the water inlet 34 of the precision filter module 3 from the electroplating solution medicine tank 1;

[0044] S3. After filtering in the precision filtration module 3, the filtrate flows out from the first water production port 31 of the precision filtration module 3, and flows back to the ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com