Temporary anchoring structure of segment prefabricated assembled concrete box girder and anchoring method

A concrete box girder, prefabricated assembly technology, applied in the direction of erecting/assembling bridges, bridges, bridge materials, etc., can solve the problems of unfavorable force on the main girder, complicated construction process, etc., achieve fast construction speed, guaranteed construction quality, and speed up construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

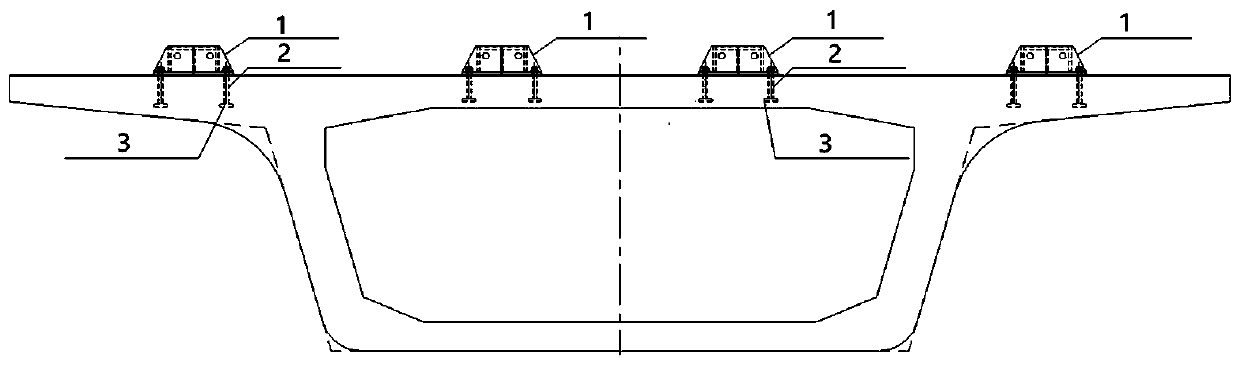

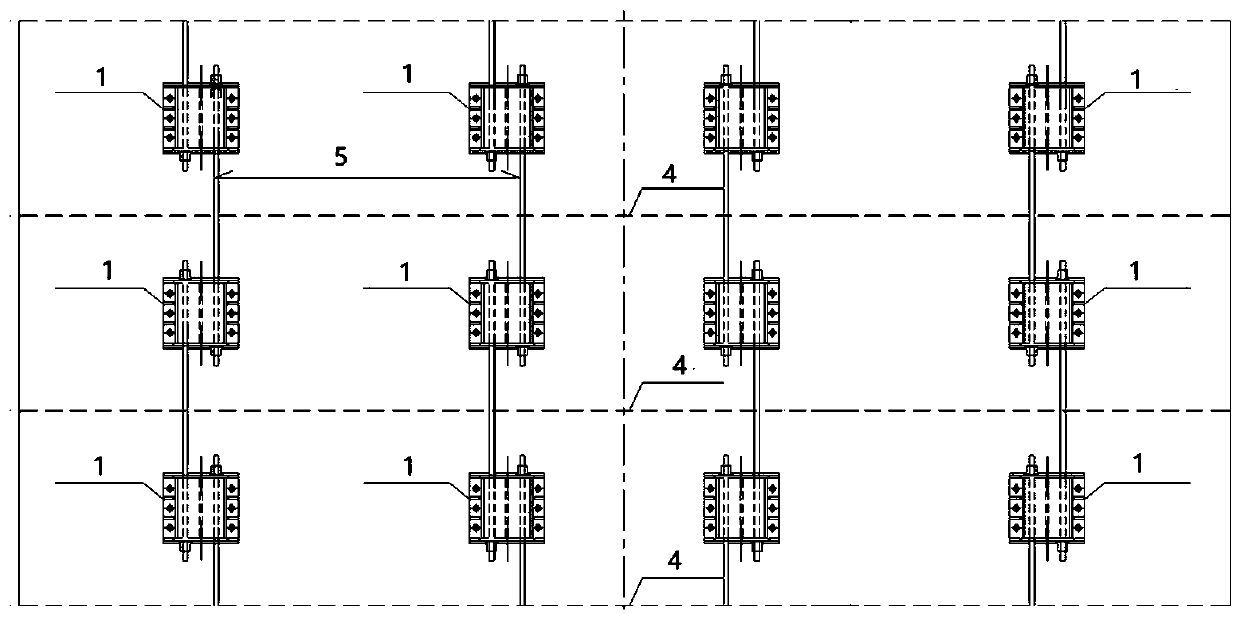

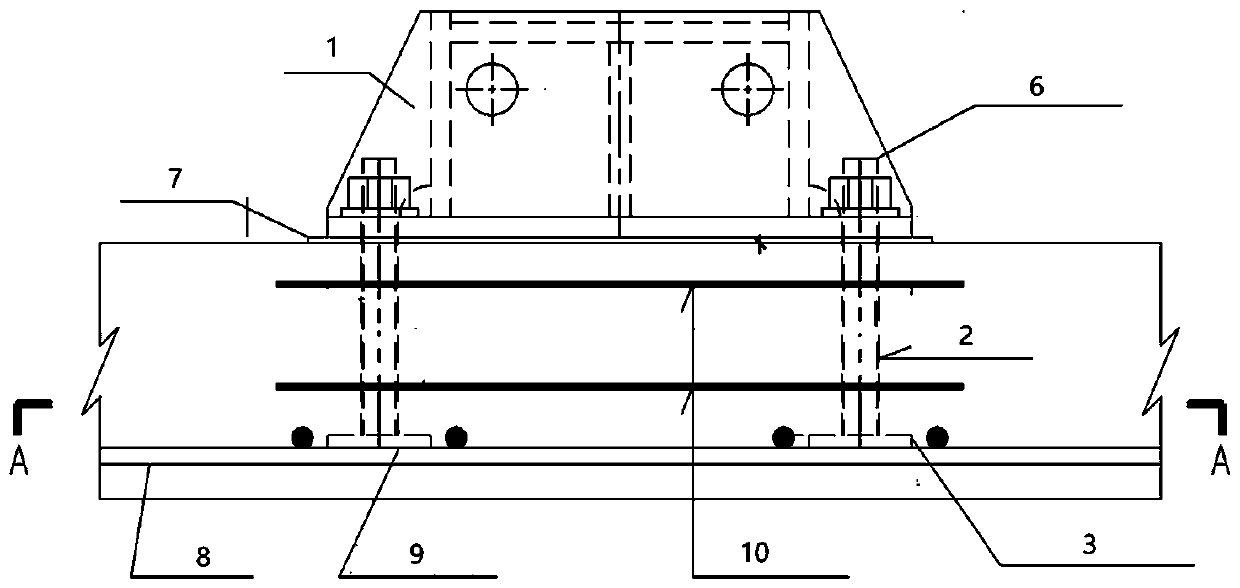

[0024] The present invention is a temporary anchoring scheme for a segmental prefabricated assembled concrete box girder. The temporary anchoring device mainly includes: (1) a sleeve 2 pre-buried in the prefabricated segmental beam; (2) a steel tooth block 1; (3) a precision Rolled rebar 5 and other components. The main implementation process is as follows: (1) According to the section form of the main beam, select the position of the temporary anchoring tooth block, such as figure 1 As shown, it is generally installed symmetrically on both sides of the web for anchoring, and the anchoring position must avoid the position of the prestressed steel beam. (2) Pre-embed the sleeve 2 on the prefabricated segmental beam, such as image 3 As shown, the steel plate 3 is welded under the sleeve 2, and the steel plate 3 is welded to the transverse steel bar 8 of the main beam ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com