A cooling system for a screw air compressor

A heat dissipation system and air compressor technology, applied in the direction of rotary piston/oscillating piston pump components, mechanical equipment, machines/engines, etc., can solve problems such as high energy consumption, impact on equipment operation, and poor cooling effect. To achieve the effect of reducing the service life, improving the heat dissipation effect, and facilitating the opening and closing operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

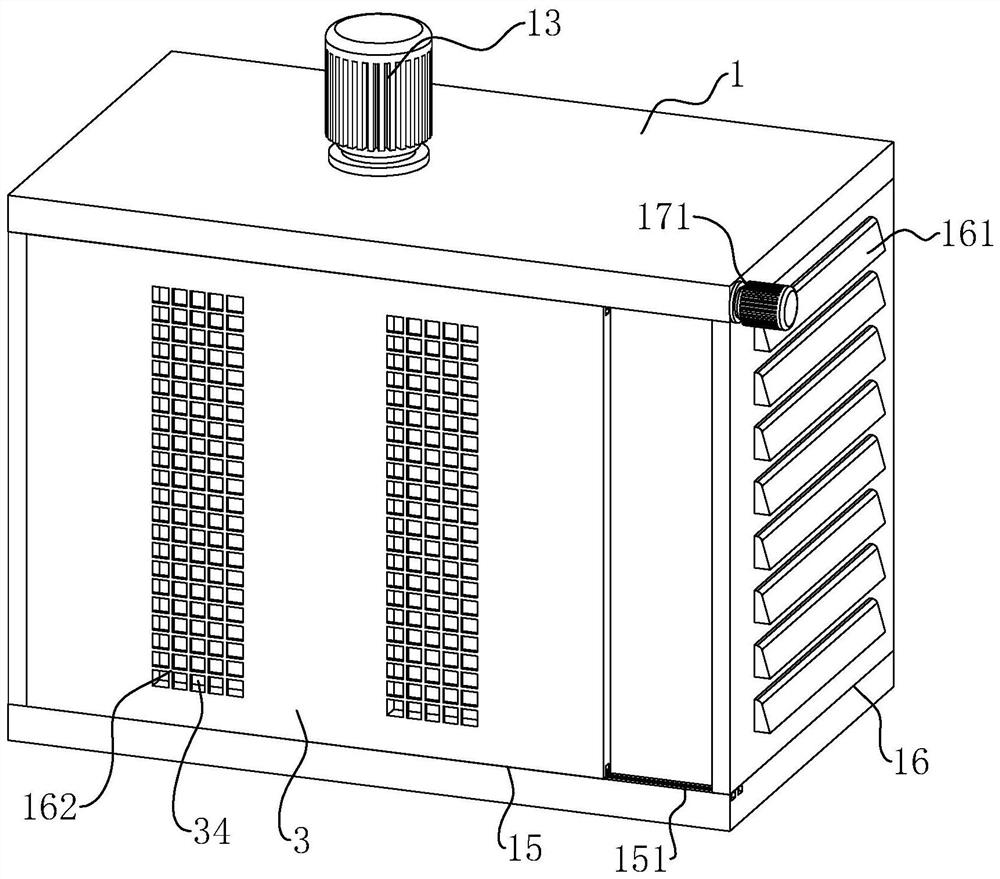

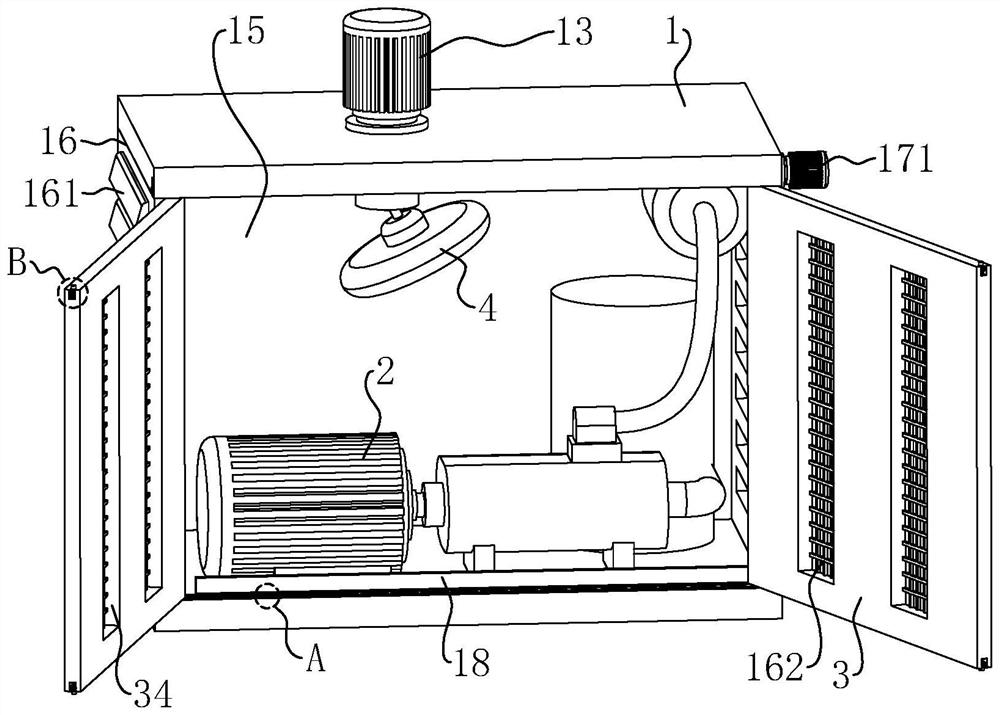

[0036] refer to figure 1 and figure 2 , is a heat dissipation system of a screw air compressor disclosed in the present invention, including an air compressor main body 2, a protective box 1 is installed on the outer side of the air compressor main body 2, and the inner side of the protective box 1 is located above the air compressor main body 2 Rotate is equipped with electric fan 4.

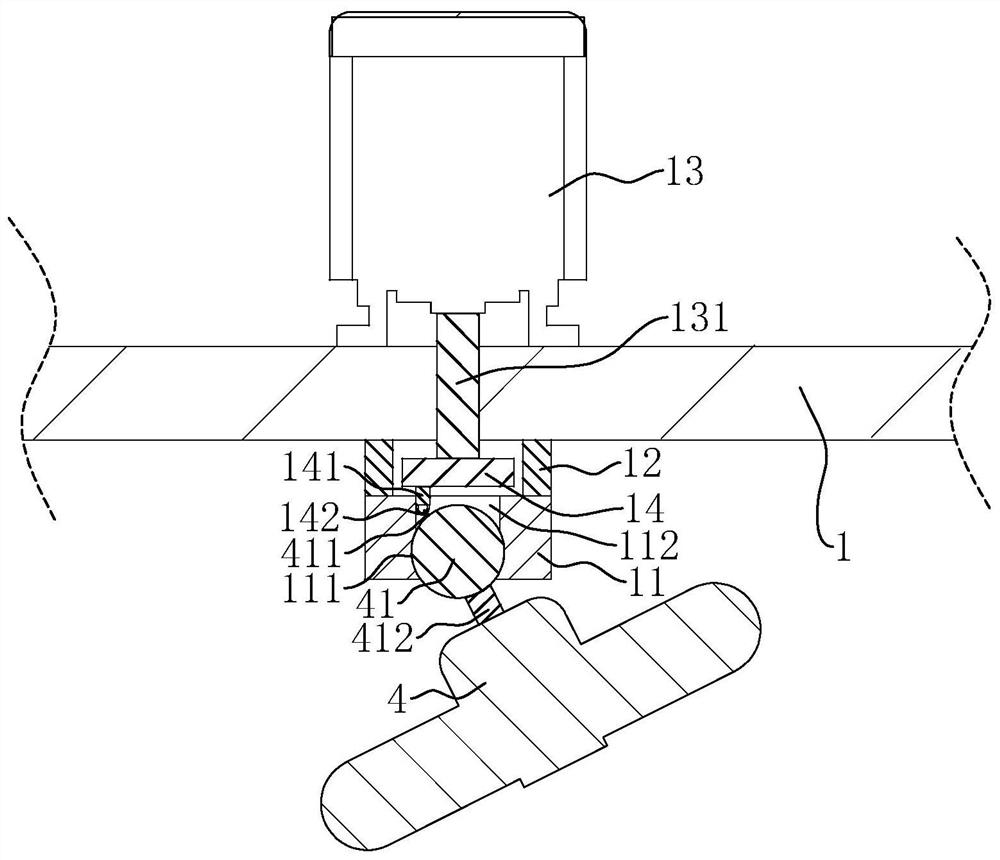

[0037] refer to figure 2 and image 3 , the inner top surface of the protective box 1 is fixed with a mounting seat 11, the mounting seat 11 is connected with the inner top of the protective box 1 through two connecting handles 12, there is a distance between the mounting seat 11 and the inner top of the protective box 1, and the electric fan 4 It is installed on the bottom surface of the mounting base 11 by a twisting mechanism. The twisting mechanism includes a ball hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com