A high-efficiency dust-removing drying equipment for textile production

A drying equipment and high-efficiency technology, which is applied in drying, drying machines, textiles and papermaking, etc., can solve the problems of increasing processing steps, reducing efficiency, and affecting the quality of fabrics, so as to reduce steps, increase efficiency, and avoid partial heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

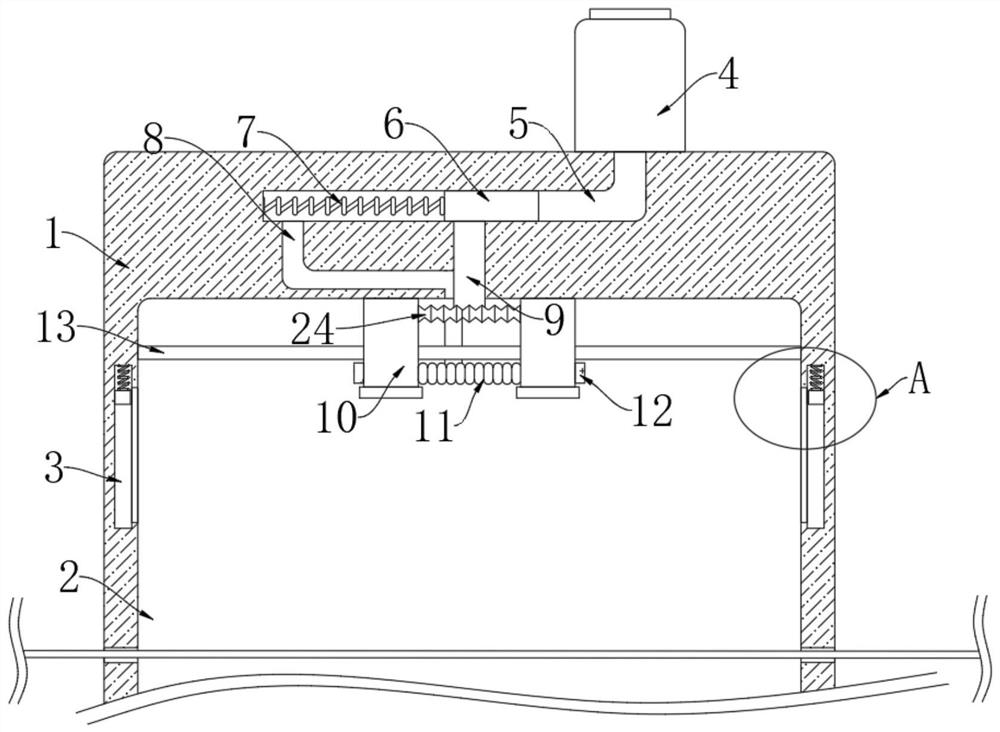

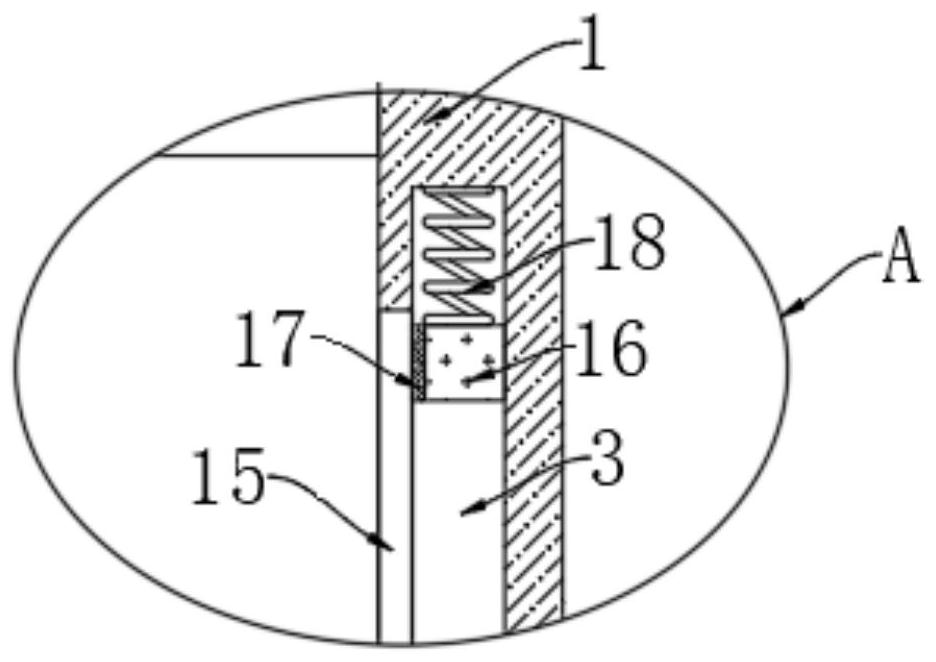

[0023] refer to Figure 1-3 , a high-efficiency dust removal type drying equipment for textile production, including a housing 1, a connecting air duct 5 and a drying chamber 2 are arranged in the housing 1, the connecting air duct 5 is located above the drying chamber 2, and the housing 1 Two vertical cavities 3 are symmetrically arranged inside, and the two vertical cavities 3 are located on both sides of the drying chamber 2, and a sliding door 14 is installed on the front side of the housing 1;

[0024] Blast mechanism, the blower mechanism includes the hot air blower 4 that is installed on the upper end of the housing 1, the air outlet of the hot air blower 4 extends to the space on the right side connecting the air duct 5, the drying chamber 2 is horizontally provided with a slide bar 13, and the bottom of the slide bar 13 The two ends are respectively fixedly connected to the inner walls of both sides of the drying chamber 2, and the sliding rod 13 is provided with two ...

Embodiment 2

[0031] refer to Figure 4-5 , The difference between this embodiment and Embodiment 1 is that the inner walls on both sides of the drying chamber 2 are fixedly connected with fixing plates 23, and the two fixing plates 23 are vertically penetrated with abutment rods 19, and each abutment The rods 19 are all slidably connected to the corresponding fixing plates 23, and each contacting rod 19 is fixedly sleeved with a connecting plate 21, and the lower end of each connecting plate 21 is elastically connected to the upper end of the corresponding fixing plate 23 through the third connecting spring 22, The upper end of each contact rod 19 is fixed with a wedge-shaped block 20, and the slopes of the two wedge-shaped blocks 20 are all facing one side of the corresponding spray head 10. Contact occurs, causing wedge block 20 to move downward.

[0032] In this embodiment, when the two nozzles 10 are moving away from each other, they will come into contact with the corresponding wedge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com