Self-expanded mechanical anchor bolt

An anchor bolt and mechanical technology, which is applied in the field of self-expanding bottom mechanical anchor bolts, can solve the problems of too many installation steps of mold expansion bottom anchor bolts, insufficient expansion, and hindering the full expansion of sleeve expansion pieces, so as to improve cutting Difficult problem of concrete hole wall, reduction of stress concentration, and improvement of expansion difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention is further described below in conjunction with accompanying drawing and embodiment:

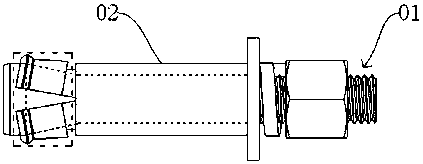

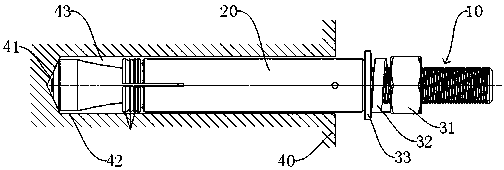

[0058] Such as figure 2 As shown, a self-expanding bottom type mechanical anchor bolt includes an anchor bolt rod 10 and a sleeve 20, the sleeve 20 is sleeved on the outside of the anchor bolt rod rod 10, and the nut 31 is sleeved on the threaded part 11 at the outer end of the anchor bolt rod rod 10, A flat washer 33 is sheathed on the threaded portion 11 , and the nut 31 is connected with the sleeve 20 through the flat washer 33 . Preferably, a spring washer 32 is provided between the nut 31 and the flat washer 33 to increase the adjustability between the nut 31 and the flat washer 33 .

[0059] 1. Anchor bolt 10

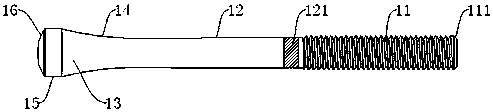

[0060] Such as image 3 As shown, the anchor screw 10 includes a polished rod portion 12 and an expanded portion and a threaded portion 11 disposed on both sides of the polished rod portion 12 .

[0061] 1. Threaded part 11

[0062] The end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com