Anti-freezing control method and gas water heater

A technology of a gas water heater and a control method, which is applied in the direction of fluid heaters, lighting and heating equipment, etc., and can solve problems such as freezing and cracking of waterways or components, and achieve the effects of simple control methods, avoiding property losses, and reducing failure rates in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

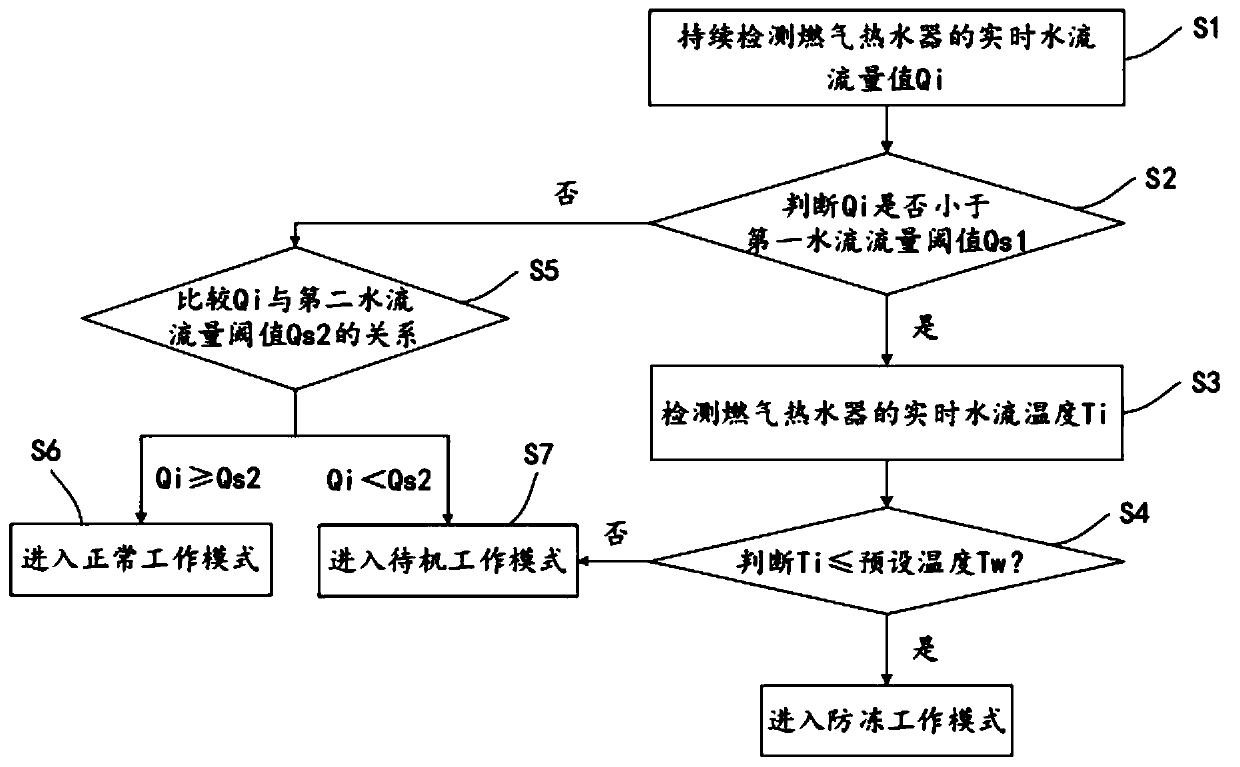

[0040] Such as figure 1 Shown, a kind of antifreeze control method, comprises the steps:

[0041] S1: Continuously detect the real-time water flow value Qi of the gas water heater through the water flow detection device;

[0042] Specifically, the water flow detection device is installed in the waterway system of the gas water heater and is electrically connected with the control module of the gas water heater. The real-time water flow value Qi in the waterway system is continuously detected by the water flow detection device. The detected real-time water flow value Qi is compared with at least one preset value, which is used to determine that the water flow in the waterway system meets the preset water flow value in any of the working modes of the gas water heater entering the antifreeze, standby or normal working mode .

[0043] S2: Determine whether the real-time water flow value Qi is less than the first water flow threshold Qs1, if so, enter step S3, otherwise the gas w...

Embodiment 2

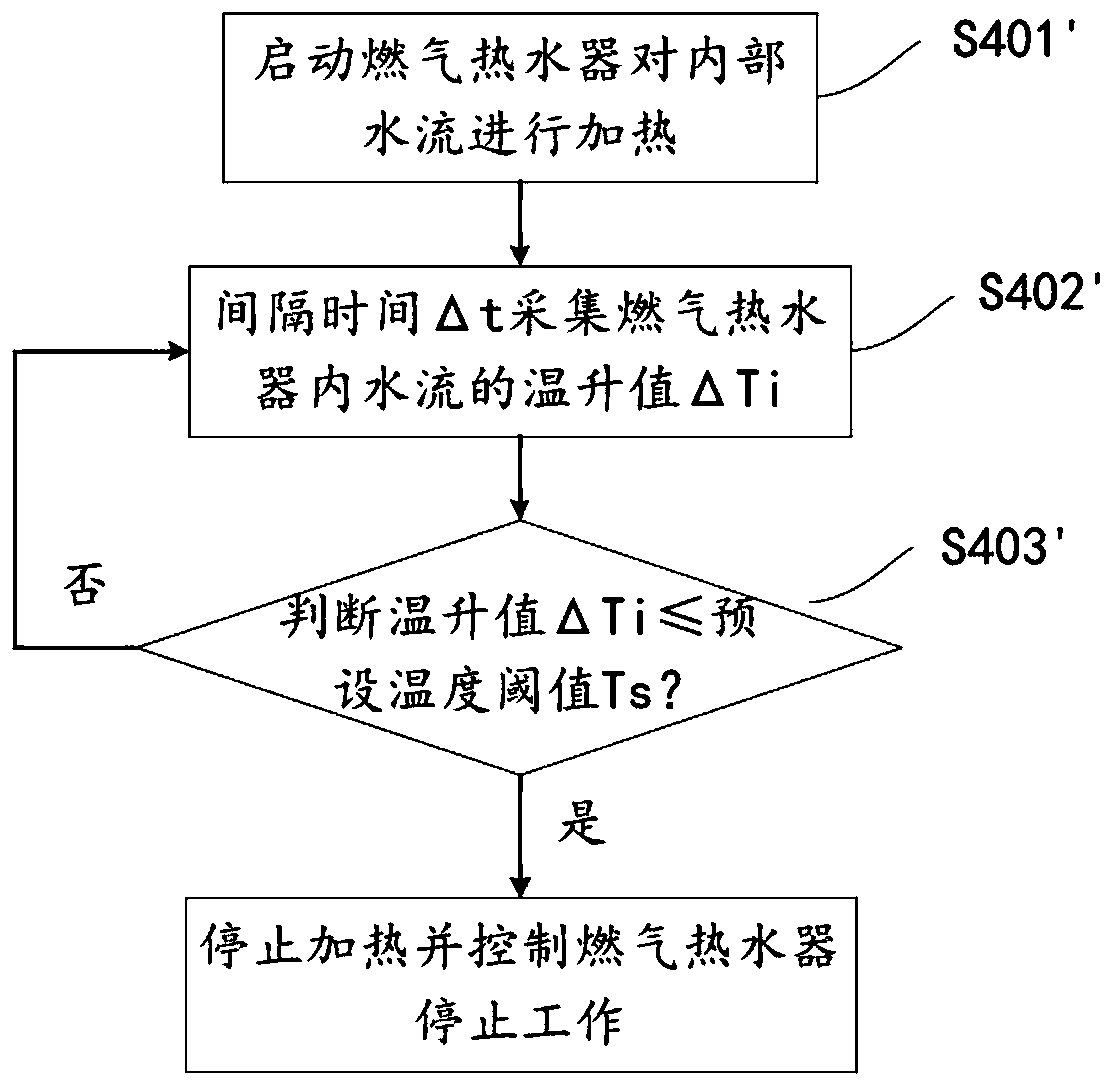

[0058] Such as image 3 As shown, the difference between this embodiment and Embodiment 1 is that the control method for ending the antifreeze working mode is different. Specifically, after the gas water heater enters the antifreeze working mode, further steps are included:

[0059] S401': Start the gas water heater to heat the internal water flow;

[0060] S402': collect the temperature rise value ΔTi of the water flow in the gas water heater through the temperature detection device interval time Δt;

[0061] Specifically, the temperature detection device in the waterway system collects the current water flow temperature Ti in the waterway system at intervals Δt, and the control module calculates the difference between the current water flow temperature Ti and the water flow temperature T(i-1) collected last time to obtain the temperature Appreciation ΔTi.

[0062] S403': Determine whether the temperature rise value ΔTi is less than or equal to the preset temperature thres...

Embodiment 3

[0071] Such as Figure 5 As shown, a gas water heater in this embodiment includes a water heater body 1, a water system with a water inlet pipe 2 and a water outlet pipe 3, and a gas control valve 4, which also includes: a water flow detection device 5, which is arranged on the water inlet pipe 2 or On the water outlet pipe 3, it is used for the real-time water flow value Qi of the water inlet pipe 2 or the water outlet pipe 3; the control module 6, the water flow detection device 5 and the gas control valve 4 are respectively electrically connected to the control module 6 for obtaining and judging the water inlet pipe 2 Or the relationship between the real-time water flow value Qi of the outlet pipe 3 and the first water flow threshold Qs1, and determine the working mode of the gas water heater based on the judgment result. Preferably, the water flow detection device 5 of this embodiment is arranged on the water inlet pipe 2 .

[0072] Further, it also includes: a temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com