Automatic marinating control device and process

An automatic control device and brine-making technology, which is applied in the field of control devices in distributed salt fields, can solve the problems of multiple points and wide areas and large influence, and achieve the effect of remote operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

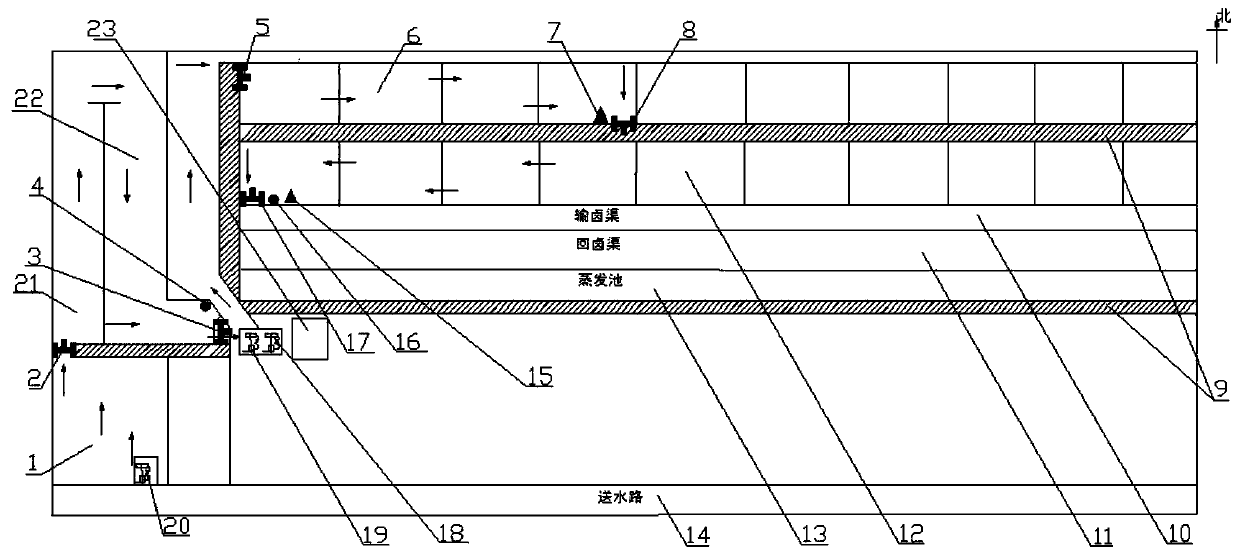

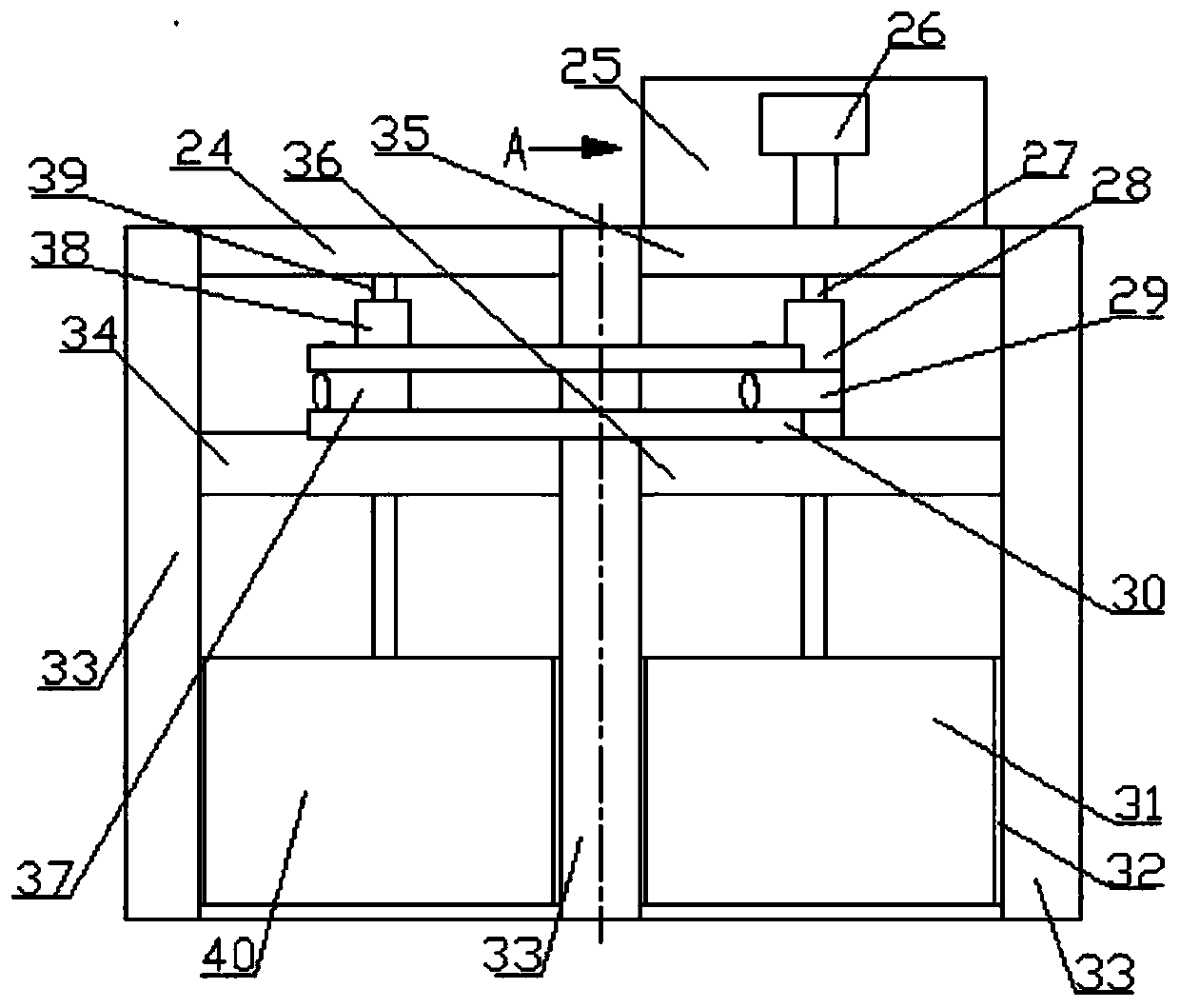

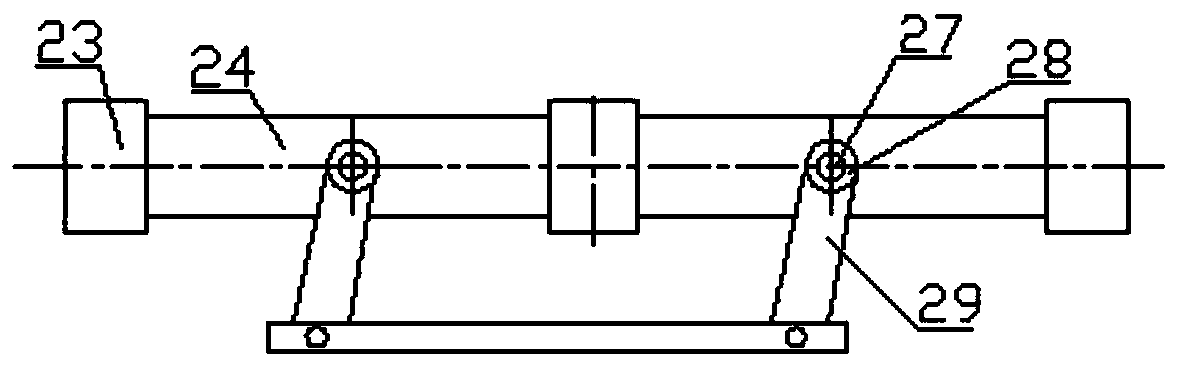

[0035] A halogen automatic control device, see attached figure 1 to the attached Figure 4 , figure 1 Middle: upstream evaporation pool 1, upstream evaporation pool control gate 2, upstream evaporation pool 3 outlet gate 3, first density meter 4, water storage zone 1 inlet gate 5, water storage zone 6, first liquid level gauge 7, Water storage area sluice gate 8, brine production area road 9, brine transportation channel 10, brine return channel 11, second water storage area 12, evaporation pond 13, water supply channel 14, second liquid level meter 15, second density meter 16, Water storage zone 2 outlet gate 17, upstream evaporation pond 3 outlet first outlet pump 18, upstream evaporation pond 3 outlet second outlet pump 19, upstream evaporating pond inlet pump 20, upstream evaporating pond 2 21, upstream evaporating pond 3 22, white water computer room 23;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com