Method for manufacturing three-color LED lamp bead

A technology of LED lamp beads and manufacturing methods, which is applied in the direction of semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as unsatisfactory product light angle, consistency, and complicated manufacturing methods, and achieve tight arrangement and improved smoothness Degree, to avoid the effect of sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

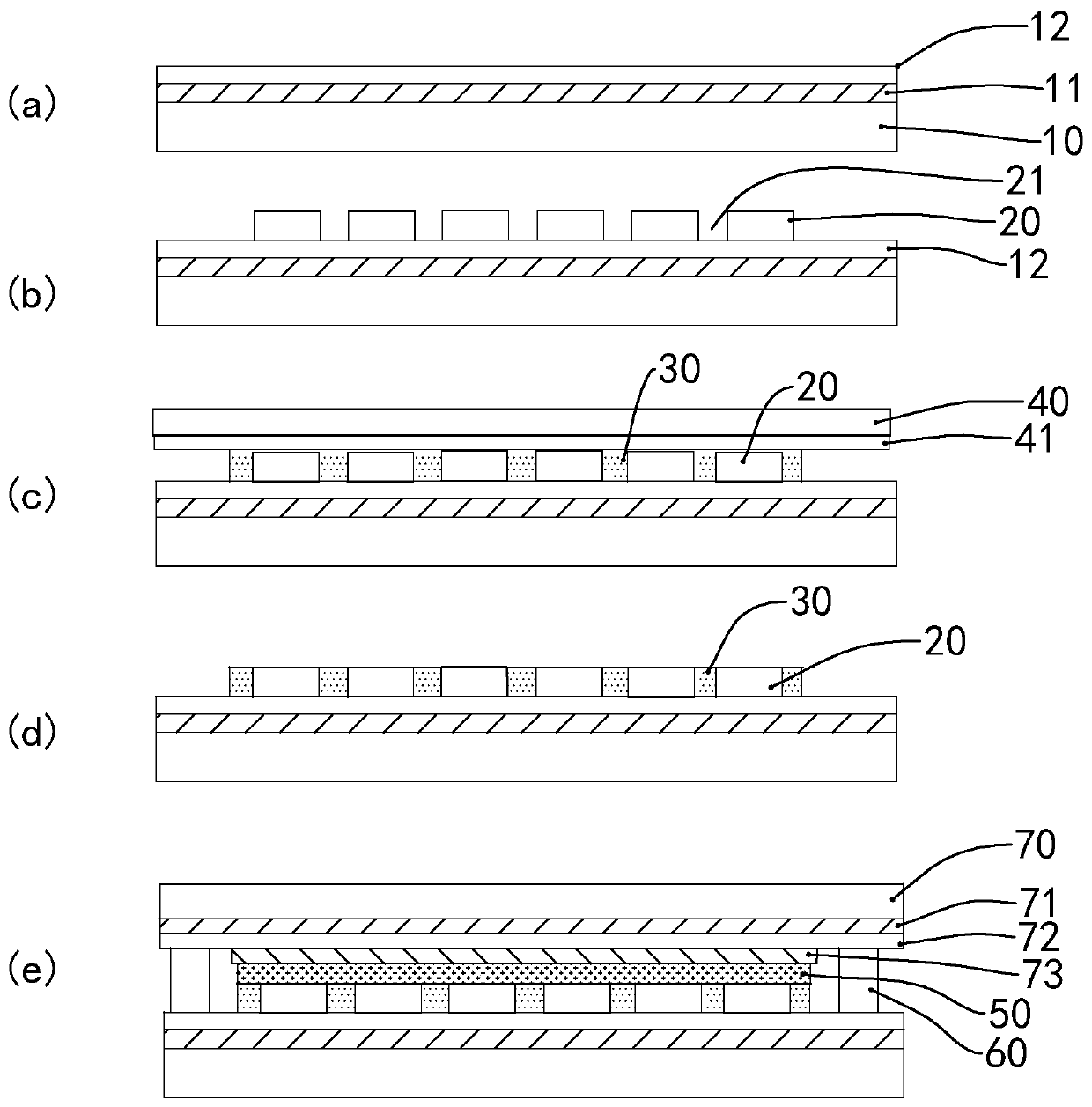

[0041] The manufacturing method of the three-color LED lamp bead of this embodiment includes the following steps:

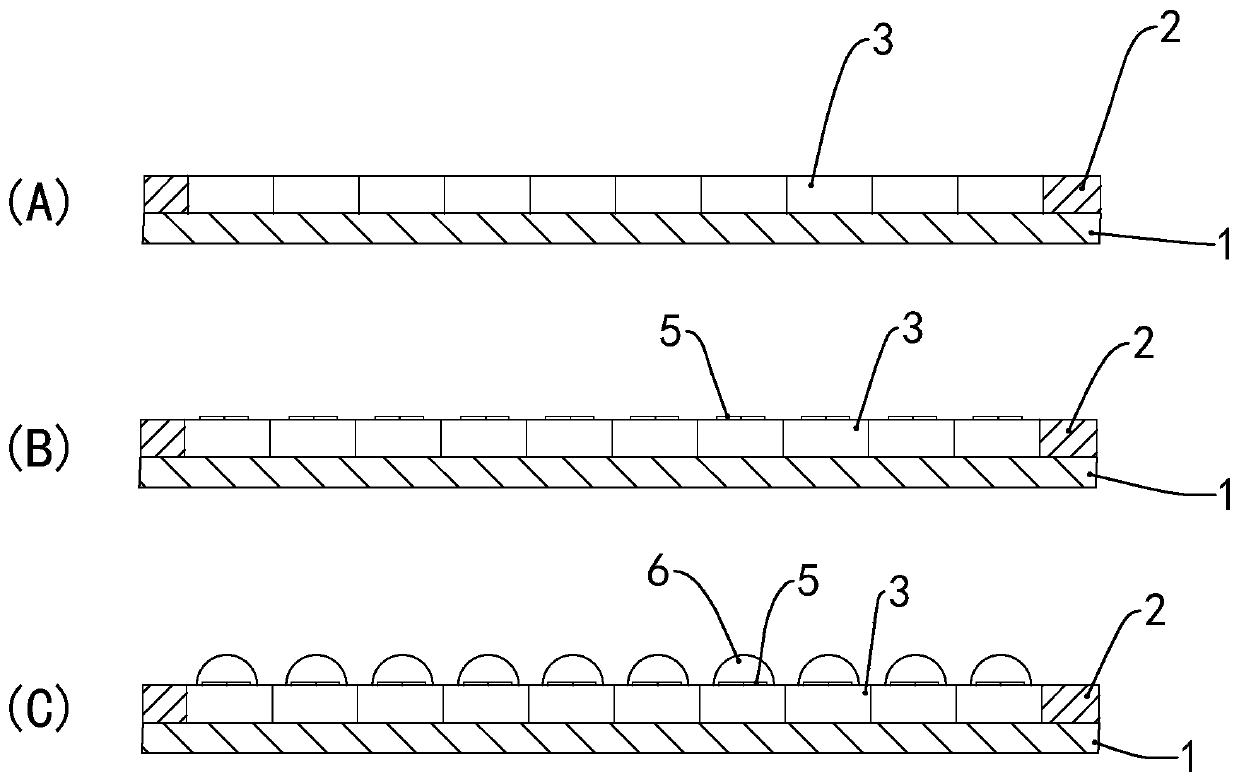

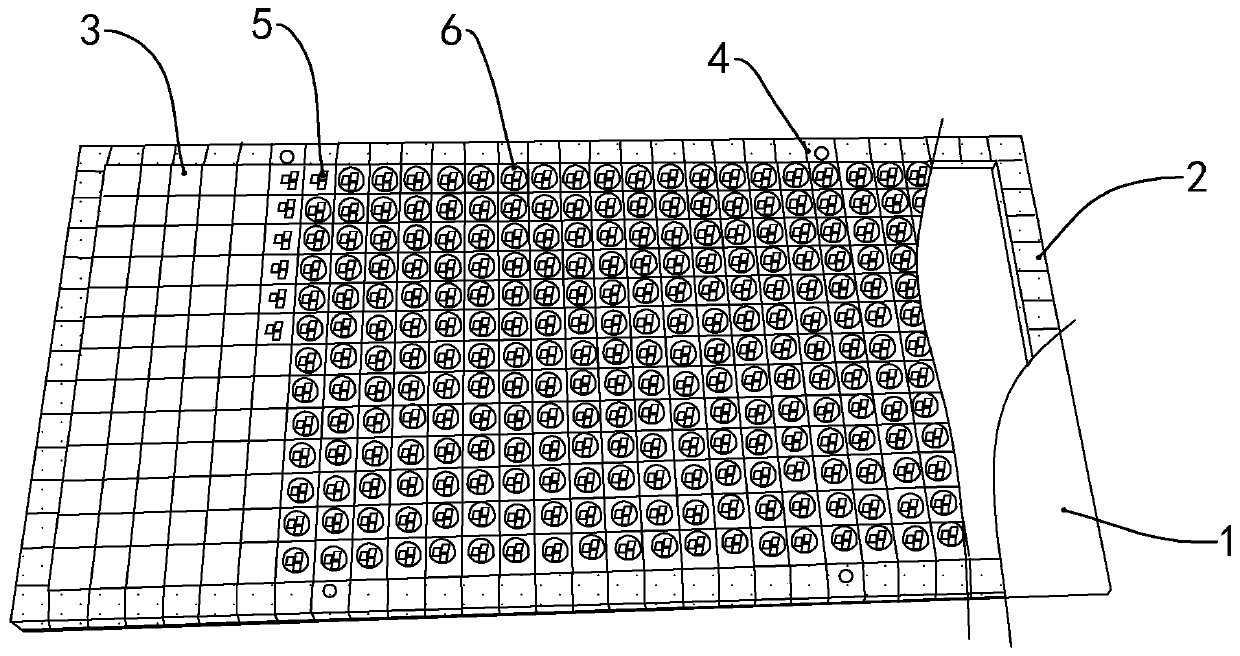

[0042] Step A: If figure 1 (A) and figure 2 As shown, the UV film 1 is prepared, the edge of the UV film 1 is provided with a process edge 2, and a matrix array of substrates 3 is pasted in the area surrounded by the process edge 2 on the UV film 1, and the matrix array is full of the area. The process side 2 is provided with positioning marks 4 corresponding to the matrix array. In the matrix array, the substrates 3 are arranged in parallel so as to be connected to each other. In this embodiment, the UV film 1 is rectangular, and the process side 2 is arranged on four sides of the UV film 1; the substrate 3 is a square aluminum substrate.

[0043] Step B: If figure 1 (B) and figure 2 As shown, according to the positioning mark 4, the three-color LED CSP 5 is connected to each substrate 3 with solder paste. CSPs can be connected to each substrate 3 in a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com