Treatment method of butanone residues containing acrylic acid adhesives

A treatment method and adhesive technology, applied in the direction of reagents, plastic recycling, educts, etc., can solve the problems of furnace deflagration, low efficiency, waste, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

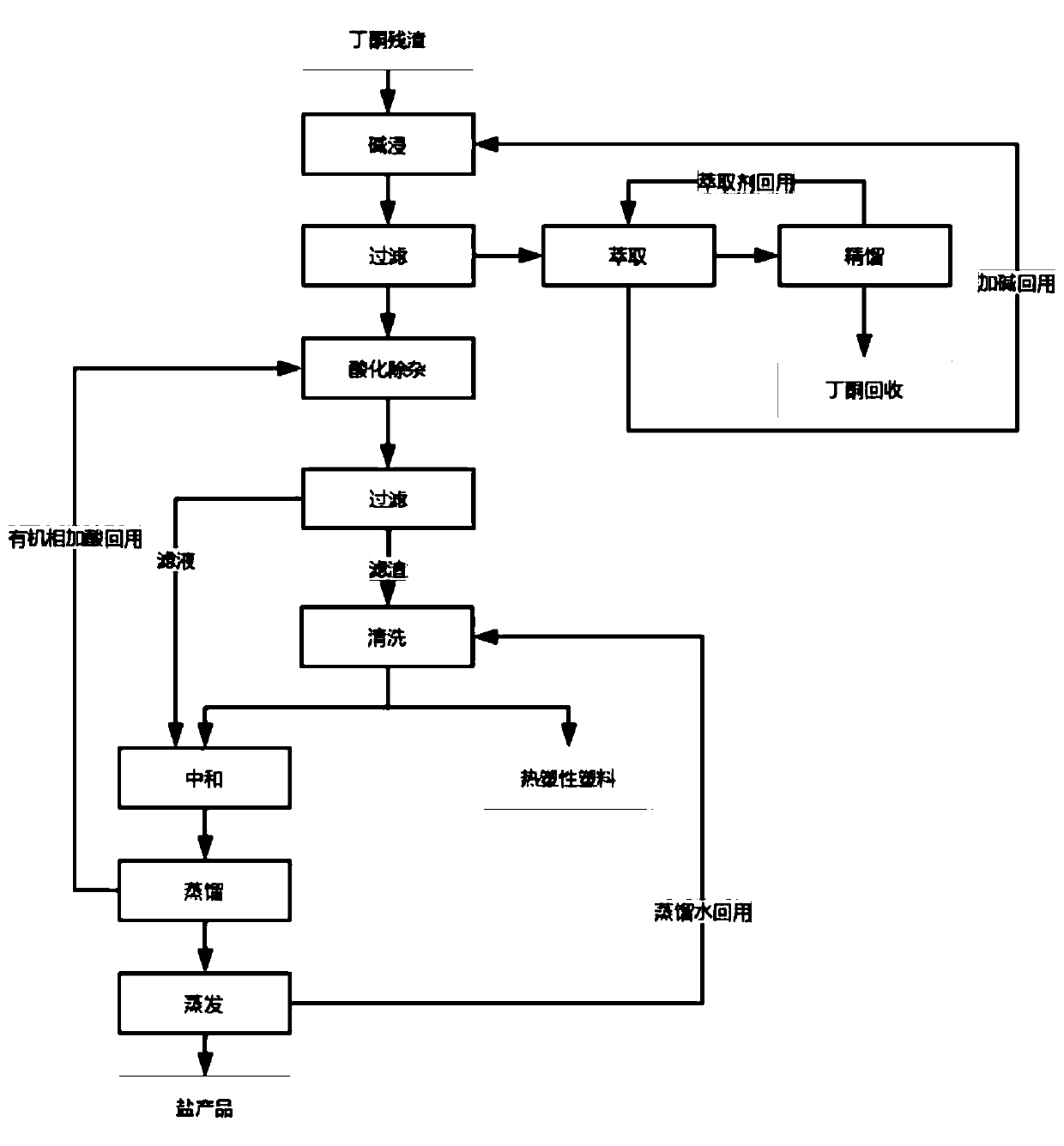

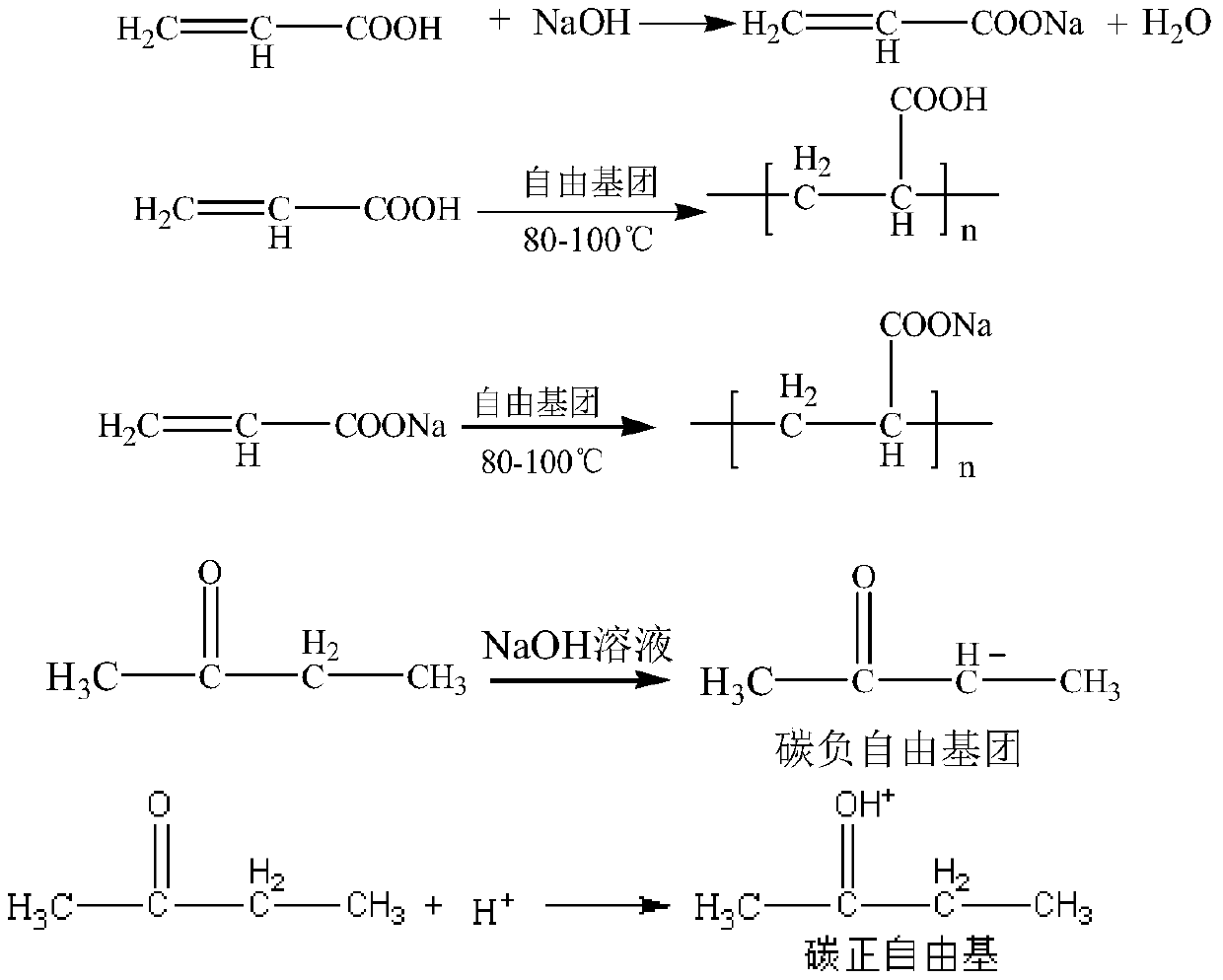

Method used

Image

Examples

Embodiment 1

[0033] Add 500g of alkali solution with a mass fraction of 20% to 100g of butanone distillation residue and heat it at 90°C. After keeping for 6h, the residue solidifies into a whole piece floating on the surface of the solution, and is filtered to separate the solid and liquid to obtain 125g of yellow solid in the upper layer and butanone / water mixed solution 475g, the mixed solution is extracted by glycerin to obtain butanone and alkali solution, the organic phase is recovered by rectification butanone, glycerin is reused as extractant, and the alkali solution after extraction is dissolved by adding 100g of sodium hydroxide solid Reuse. Add 120g of hydrochloric acid / ethylene glycol mixed solution to 125g of yellow solid, hydrochloric acid: ethylene glycol = 1:5, wash away the small molecules, and acidify the existing polymer molecules at the same time, and add 150g of water to wash to obtain 130g of Yellow solid, thermoplastic solid. After the washing water is distilled un...

Embodiment 2

[0035] Add 400g of 40% lye to 200g of methyl ethyl ketone distillation residue and heat it at 70°C. After keeping for 3 hours, the residue solidifies into a whole piece floating on the surface of the solution, filters to separate the solid and liquid, and mixes 250g of the upper yellow solid with methyl ethyl ketone / water Solution 350g, the mixed solution is extracted by dichloromethane to separate butanone and alkali solution, the organic phase is recovered by rectification butanone, dichloromethane is reused as the extraction agent, and the extracted alkali solution is dissolved by adding 160g of sodium hydroxide solid for reuse. Add 500g of sulfuric acid / methanol mixed solution to 250g of yellow solid, sulfuric acid:methanol=1:10, wash away the small molecules, and acidify the existing polymer molecules, and add 300g of clear water to wash to obtain 260g of light yellow solid, namely Thermoplastic solid. After the washing water is distilled at 60°C, 50 g of sulfuric acid i...

Embodiment 3

[0037] Add 330g of 50% lye to 120g of butanone distillation residue and heat it at 90°C for 1 hour, the residue solidifies into a whole piece floating on the surface of the solution, filters to separate the solid and liquid, and mixes 150g of the upper yellow solid with butanone / water Solution 300g, the mixed solution is extracted by dimethylacetamide, butanone and alkali solution are separated, the organic phase is recovered by rectification butanone, dimethylacetamide is reused as the extraction agent, and the extracted alkali solution is 165g sodium hydroxide for reuse. Add 200 g of hydrochloric acid / ethanol mixed solution to 150 g of yellow solid, hydrochloric acid: ethanol = 1:8, wash away the small molecules, and acidify the existing polymer molecules, and add 180 g of clear water to wash to obtain 160 g of light yellow solid, namely Thermoplastic solid. After the washing water is distilled at 60°C, ethanol is separated, and 25g of hydrochloric acid is added for reuse a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com