Two-stage sludge drying method for energy saving and environmental protection

A technology of sludge drying, energy saving and environmental protection, applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of difficulty in generalization, non-environmental protection, large investment in equipment, etc., and achieve flexible product use and less secondary pollution , the effect of low investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] The weight moisture content of the dewatered sludge of the sewage plant is 80%, and the specific gravity is 660kg / m 3 , the weight content of organic matter (VS) is 61%, and the lower calorific value is 500kJ kg -1 ;

[0025] see figure 1 , the method of the present invention, comprises the steps:

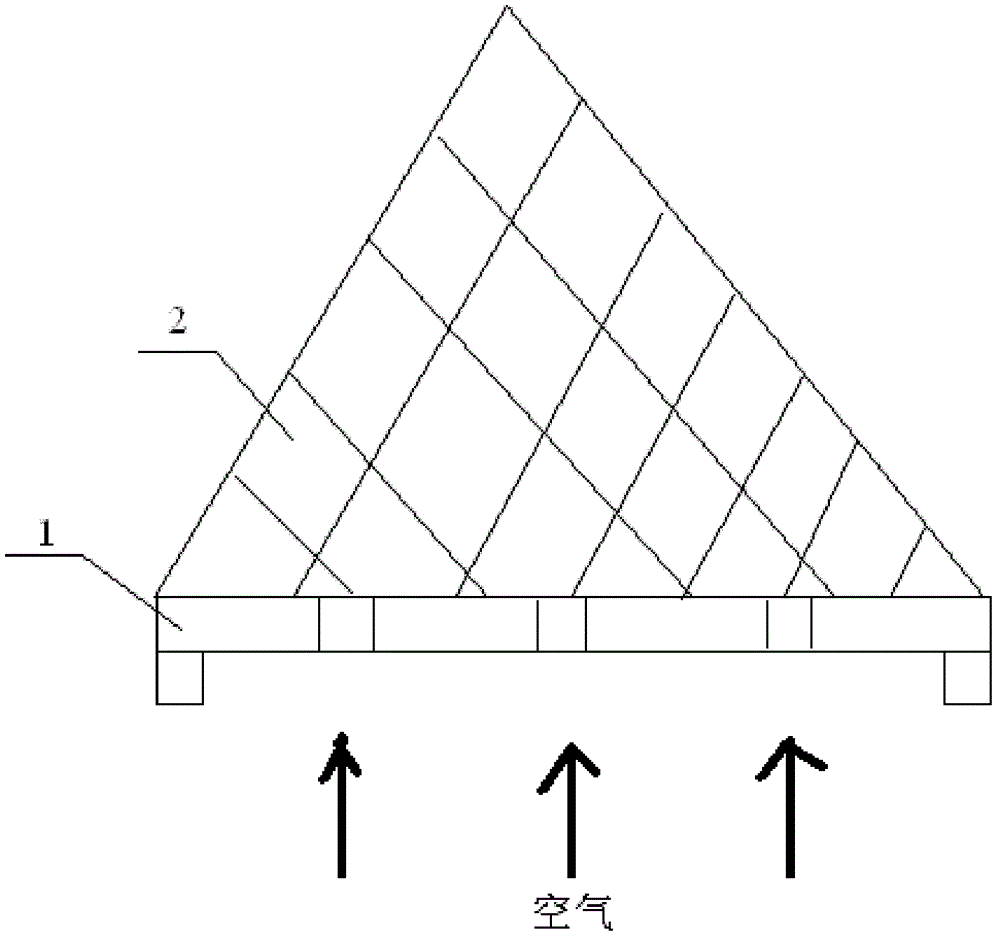

[0026] (1) Add the additive to the dewatered sludge of the sewage plant, and pile it into a pile 2, which is placed on the ventilation frame 1. The thickness of the pile is 1 meter, and the air is introduced from the lower part of the ventilation frame. In the first 10 days, every 25 minutes , open air for 8 minutes; after 10 days: every 12 minutes, open air for 45 minutes;

[0027] Turn over once every 2 days, ventilation rate is 0.05(m 3 h -1 kg -1 ) conditions, after 20 days of biological flooding, a section of dewatered sludge was obtained;

[0028] The additive is selected from rice straw, and the added weight of the additive is 15% of the dewatered sludge of the...

Embodiment 2

[0033] The weight moisture content of the dewatered sludge of the sewage plant is 70%, and the specific gravity is 750kg / m 3 , the weight content of organic matter (VS) is 70%, and the lower calorific value is 760kJ·kg -1 ;

[0034] see figure 1 , the method of the present invention, comprises the steps:

[0035] (1) Add the additive to the dewatered sludge of the sewage plant, and pile it into a heap 2, which is mounted on the ventilation frame 1. The thickness of the pile is 2 meters, and the air is introduced from the lower part of the ventilation frame 1. In the first 10 days, every interval After 15 minutes, the air was injected for 12 minutes; after 10 days: every 8 minutes, the air was injected for 55 minutes;

[0036] Turn over once every 4 days, the ventilation rate is 0.1(m 3 h -1 kg -1 ) conditions, after 15 days of biological flooding, a section of dewatered sludge was obtained;

[0037] The additive is selected from a mixture of rice straw and sawdust, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| heating value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com