Seventy-two-slot six-layer flat copper wire mixed winding structure and motor using winding structure

A hybrid winding and flat copper wire technology is applied to the motor winding structure and the motor field applying the winding structure. The effect of simplifying the layout of the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

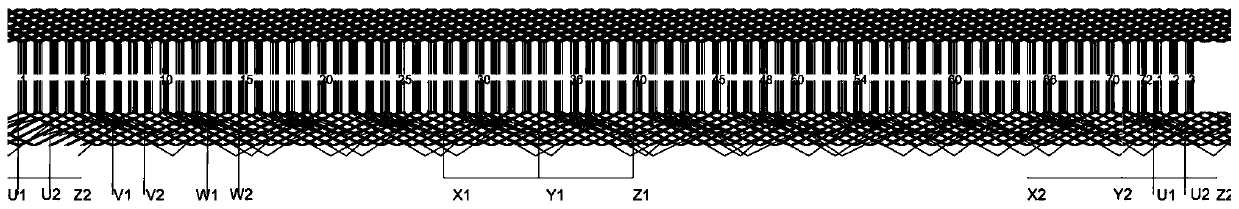

[0025] Such as figure 1 and figure 2 As shown, the 72-slot 6-layer flat copper wire hybrid winding structure of the present invention includes a three-phase hybrid winding structure distributed in at least six winding layers, and each phase hybrid winding structure includes 2 winding branches composed of a plurality of winding units road. The winding units on each winding branch are distributed in 6 pairs of poles, and the number of winding units distributed under each pole is different. The number of winding units of a winding branch under 8 poles is distributed as follows: 9, 6, 6, 6, 9, 12, 12, 12, and the other winding branch corresponds to the winding under the pole The number of units is distributed as follows: 9, 12, 12, 12, 9, 6, 6, 6. The two winding branches form a uniform and symmetrical distribution in different winding layers.

[0026] In this embodiment, adjacent winding elements either share the same slot or are separated by a slot, and are alternately conn...

Embodiment 2

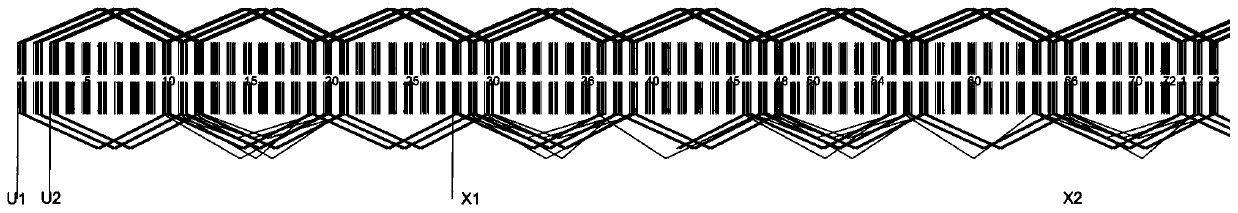

[0031] Such as image 3 As shown, an expanded view of a 72-slot, 12-pole, 6-layer flat copper wire winding structure includes a three-phase hybrid winding structure distributed in at least six winding layers. Each phase hybrid winding structure includes 2 winding branches composed of 6 winding units. The 6 winding units are distributed under 6 pairs of poles in one-to-one correspondence. Each winding unit has 6 windings connected in series through hybrid connection. Each winding branch runs through all the slot numbers of the corresponding phase, and a lower pole winding is distributed in different odd and even layers in adjacent slots.

[0032] In this embodiment, adjacent winding elements are separated by one winding layer. Each winding branch includes a U-shaped lead-out terminal and a welding terminal. The pitches of the welded ends of each winding branch are equal, which is convenient for automatic wire insertion. The lead-out wire ends of each winding branch are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com