Dirty filament defect detection method for packaged filaments

A defect detection and filament technology, applied in image data processing, instruments, calculations, etc., can solve problems such as the impact of packaged filaments, increase production labor costs, and lack of unified quality standards, to reduce production costs and improve detection. Efficiency, the effect of reducing the false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] In the following, the structure and working principle of the embodiment of the present invention will be further described in conjunction with the accompanying drawings.

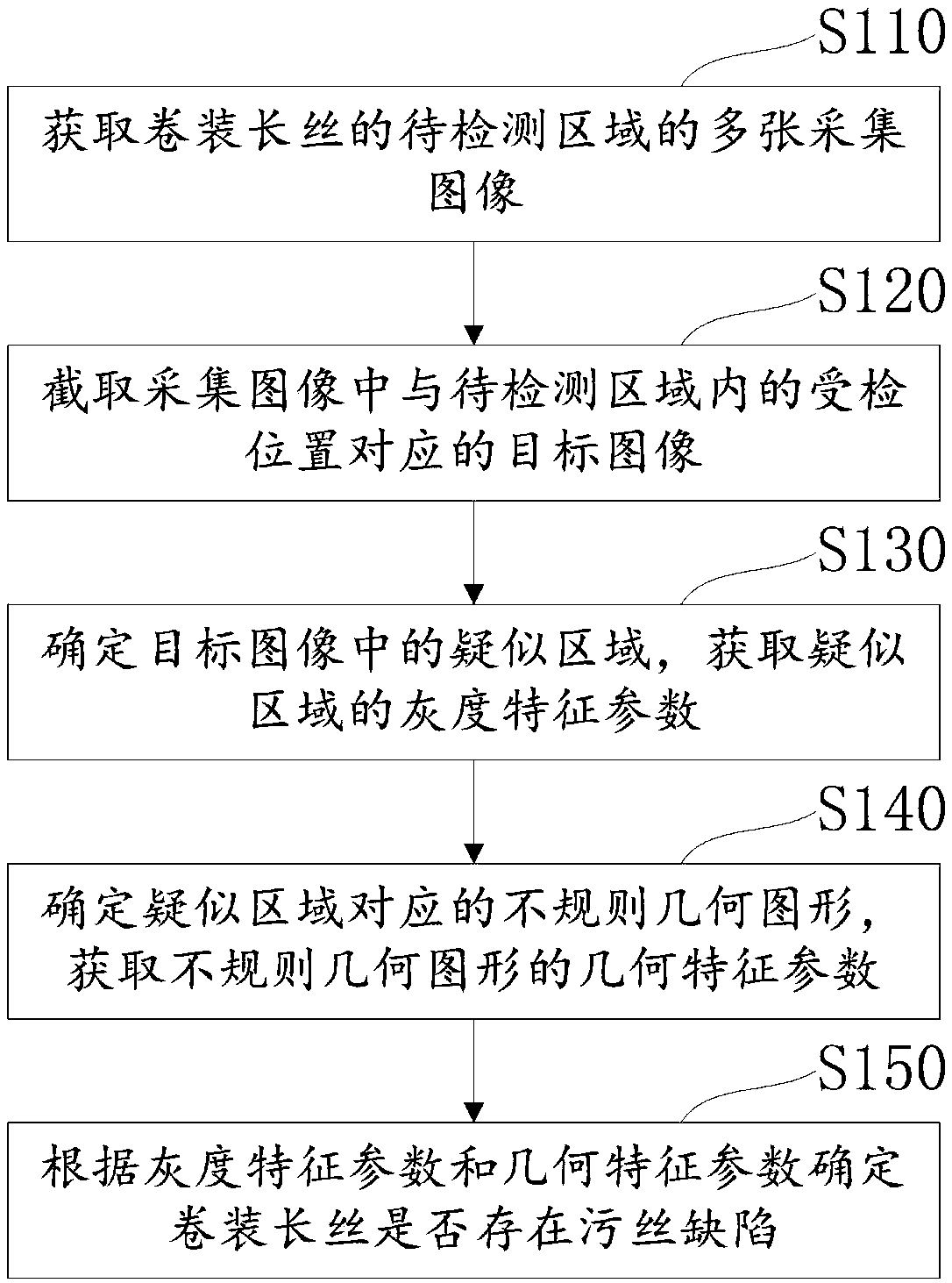

[0048] Such as figure 1 As shown, a kind of dirty silk defect detection method of packaged filament according to the embodiment of the present invention comprises:

[0049] S110. Acquiring multiple acquisition images of the region to be detected of the packaged filament;

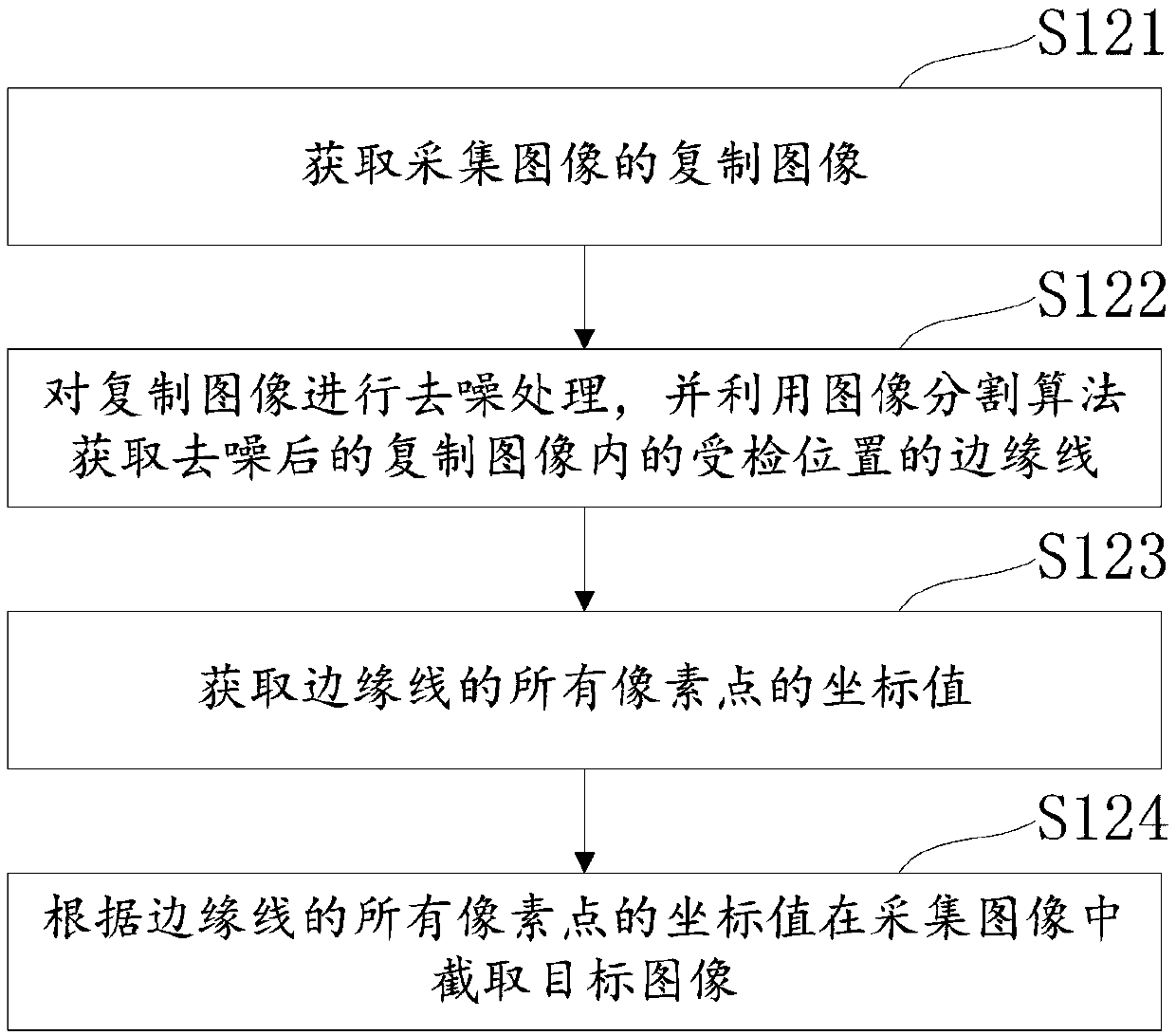

[0050] S120. Intercepting the target image corresponding to the inspected position in the area to be inspected in the collected image;

[0051] S130. Determine the suspected area in the target image, and acquire grayscale feature parameters of the suspected area;

[0052] S140 Determine the irregular geometric figure corresponding to the suspected area, and obtain the geometric characteristic parameters of the irregular geometric figure;

[0053] S150. Determine whether there is a dirty thread defect in the packaged filament acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com