Y-shaped filter capable of realizing backwashing and quickly discharging sewage

A fast sewage and filter technology, applied in the field of filters, can solve the problems of air ingress and other problems, and achieve the effect of improving work efficiency and reducing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

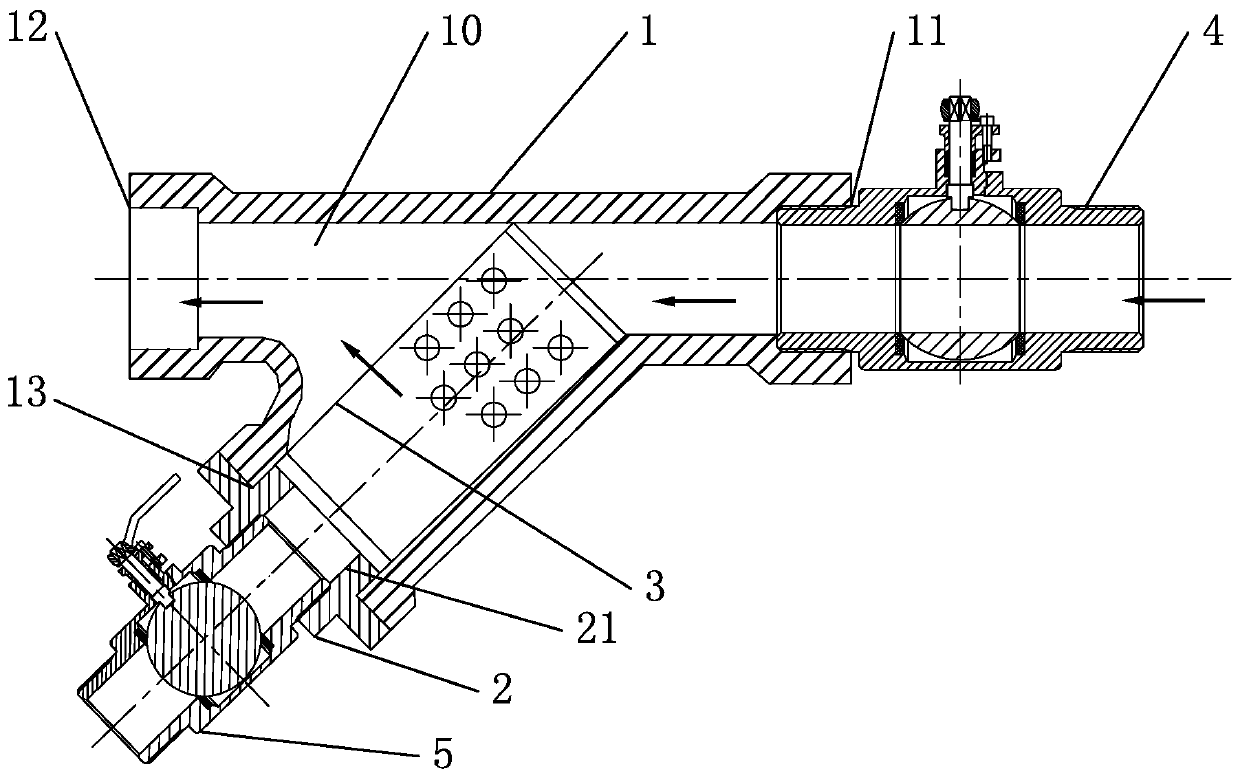

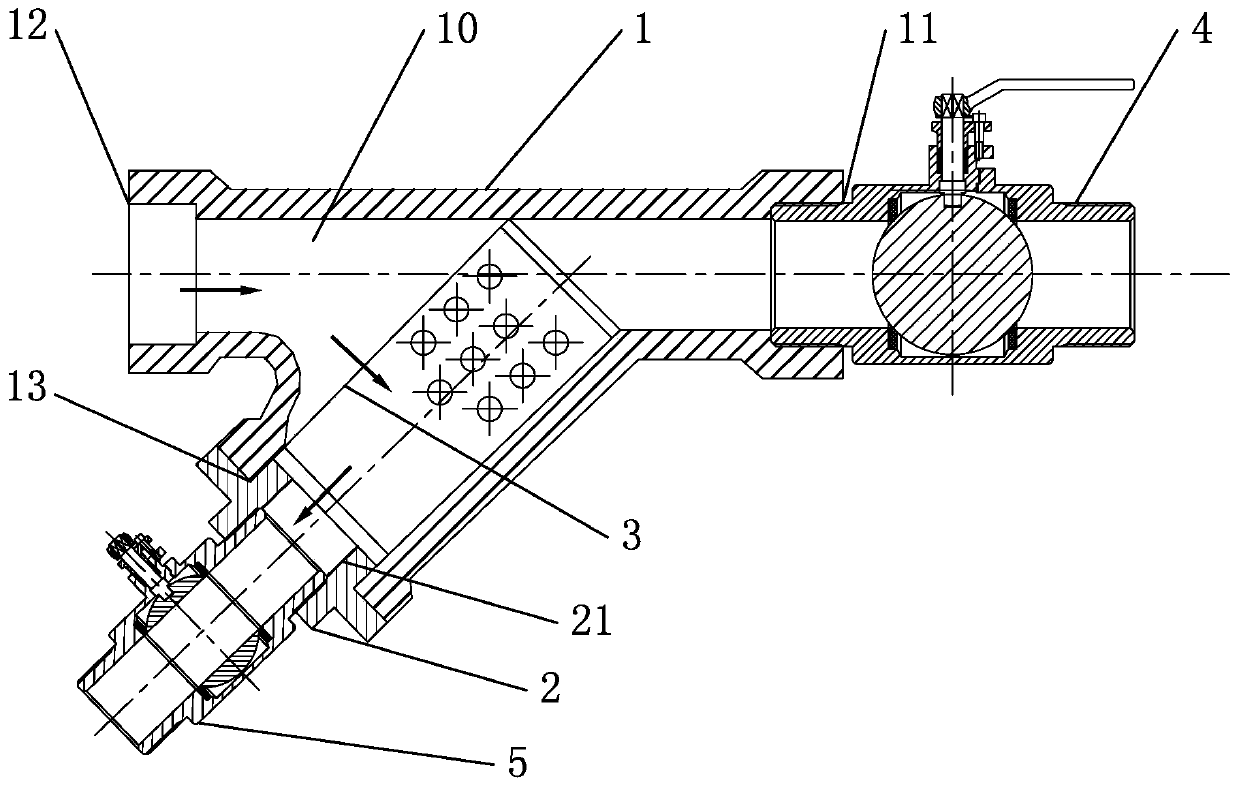

[0015] Such as figure 1 and figure 2 As shown, the Y-type filter capable of backwashing and quick sewage discharge of the present invention includes a filter body 1 and a screen cartridge 3. The filter body 1 has three ports in total, namely a fluid inlet 11 , a fluid outlet 12 and a sewage outlet 13 . The fluid inlet 11 is thread-tightly connected with the inlet ball valve 4, the sewage outlet 13 is thread-tightly connected with the transition joint 2, the other end of the transition joint 2 is thread-tightly connected with the sewage ball valve 5, and the filter cartridge 3 is installed in the filter body 1. In the cavity 10, the diameter of the sewage outlet 13 can be enough to take out the filter screen 3 cylinders, so that when the filter screen cylinder 3 breaks down, the filter screen cylinder 3 can be taken out from the sewage discharge port for replacement, and the inner diameter of the transition joint 2 is smaller than the diameter of the filter screen cylinder 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com