High-ductility and high-strength aluminum magnesium alloy sheet

An aluminum-magnesium alloy, high-strength technology, applied in the field of aluminum-magnesium alloy plates, can solve the problems of unsatisfactory ductility and strength, and achieve the effect of increasing strength, improving strength and ductility, and improving extrusion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

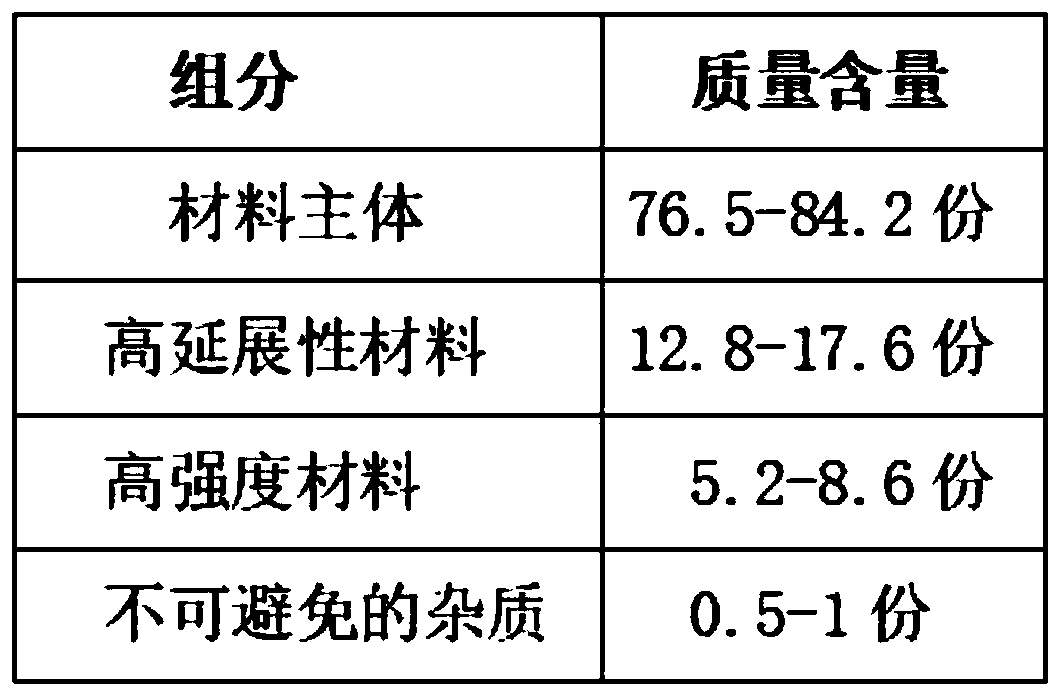

[0041] like figure 1 As mentioned above, a high-ductility and high-strength aluminum-magnesium alloy plate, its components and mass content are: 76.5-84.2 parts of the main material, 12.8-17.6 parts of the high-ductility material, 5.2-8.6 parts of the high-strength material and not Avoid impurities 0.5-1 part.

[0042] The components and mass content of the main body of the material are: 93.5-95.8 parts of Al and 5-7.6 parts of Mg. The components and mass content of the high ductility material are: Mn 33.55-45.2 parts, Mo 15.5-20.3 parts. The components and mass content of the high-strength material are: 26.8-32.3 parts of Ca, 10.2-13.4 parts of Ni, and 15.5-19.8 parts of Cu.

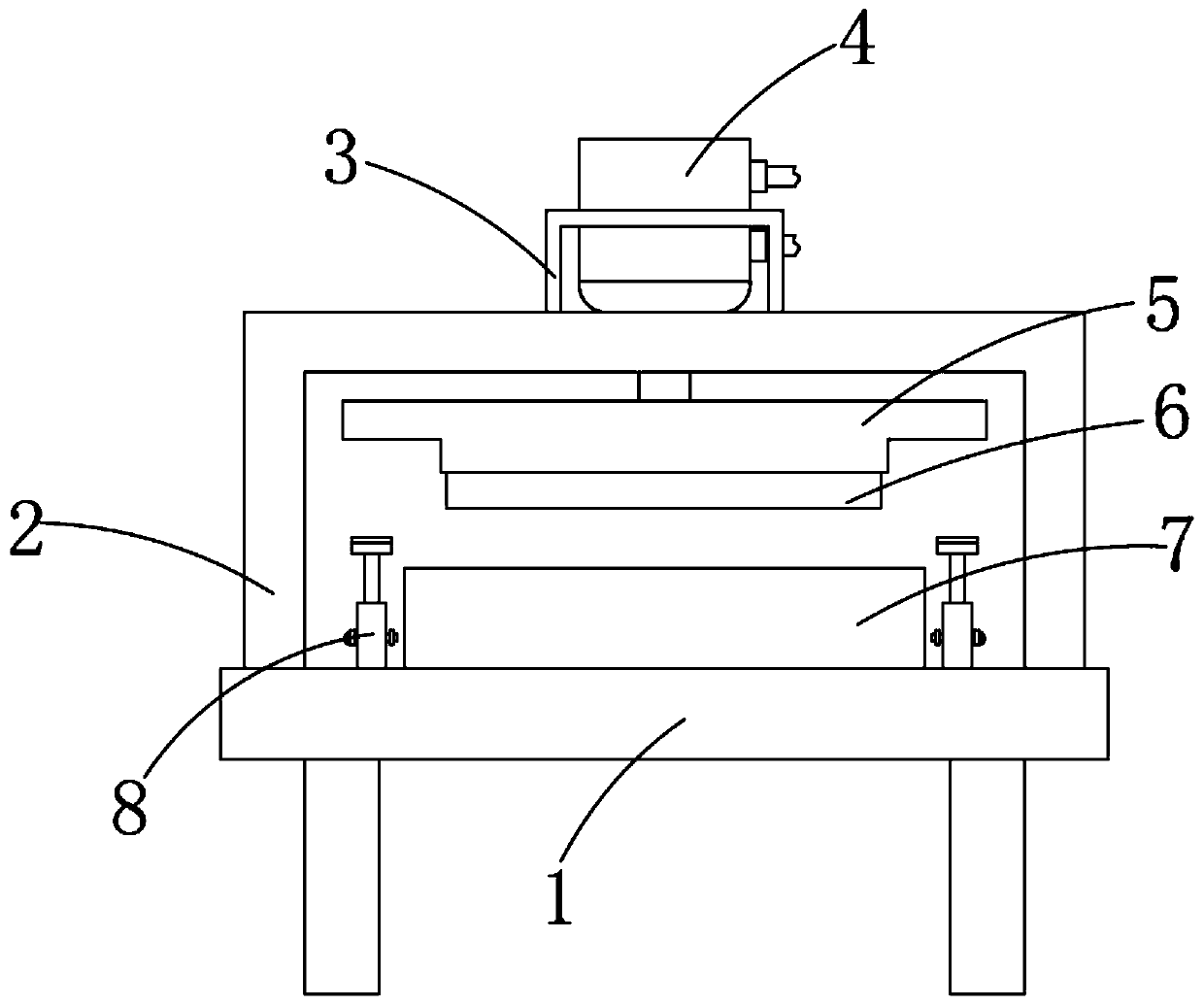

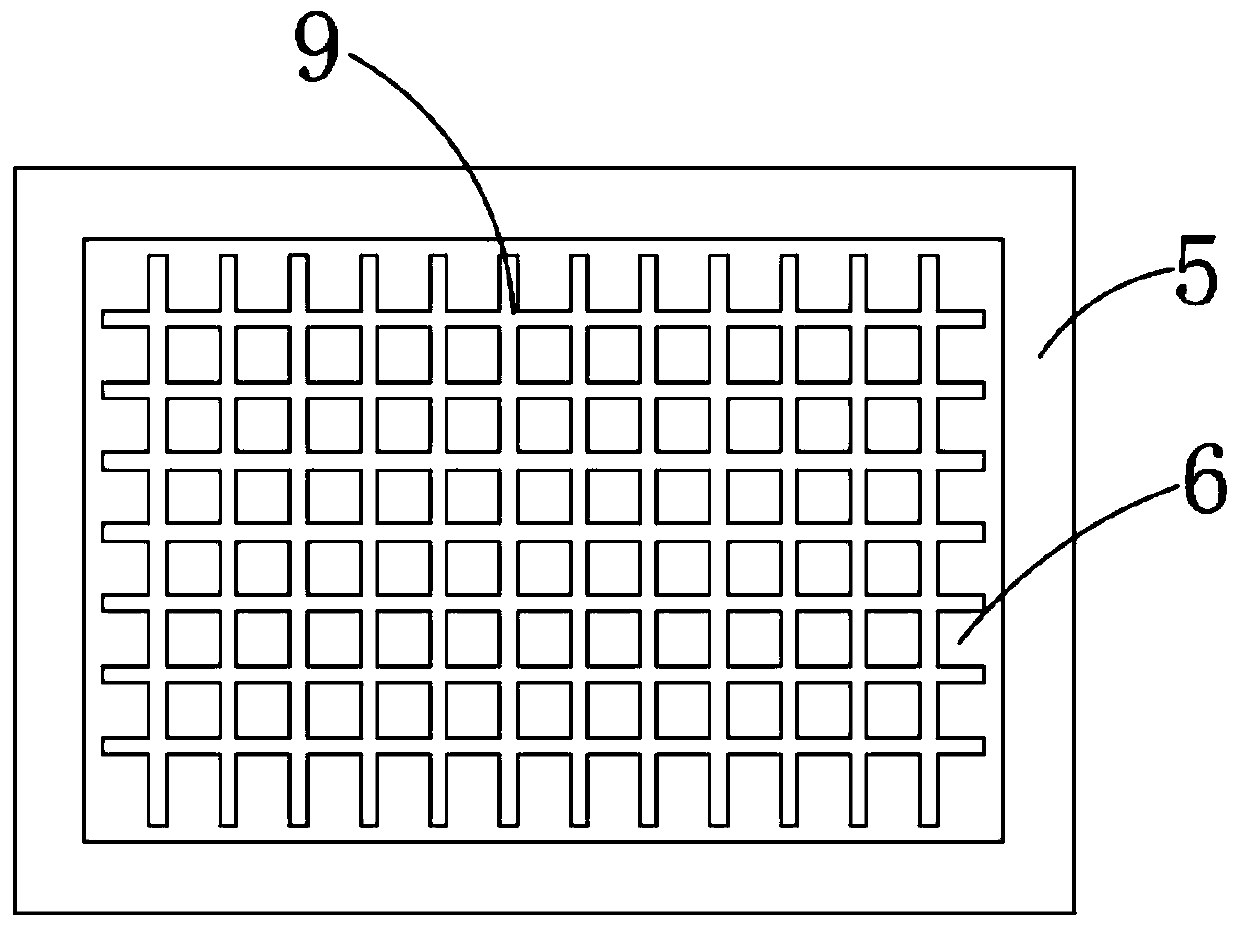

[0043] like Figure 2-5As mentioned above, the present invention also provides a high ductility and high strength aluminum-magnesium alloy plate production device, including a base 1, the upper end of the base 1 is fixedly welded with a concave frame 2, and the upper end of the concave frame 2 passes...

Embodiment 2

[0048] like figure 1 As mentioned above, a high-ductility and high-strength aluminum-magnesium alloy plate, its components and mass content are: 76.5-84.2 parts of the main material, 12.8-17.6 parts of the high-ductility material, 5.2-8.6 parts of the high-strength material and not Avoid impurities 0.5-1 part.

[0049] The components and mass content of the main body of the material are: 93.5-95.8 parts of Al and 5-7.6 parts of Mg. The components and mass content of the high ductility material are: 33.55-45.2 parts of Mn, 8.2-14.5 parts of Bi, 10.6-16.5 parts of Ce, 17.8-26.8 parts of Cn and 15.5-20.3 parts of Mo. The components and mass content of the high-strength material are: 26.8-32.3 parts of Ca, 10.2-13.4 parts of Ni, 15.5-19.8 parts of Cu, 26.7-32.1 parts of Si and 8.2-13.2 parts of Sn.

Embodiment 3

[0051] A high-ductility and high-strength aluminum-magnesium alloy plate, its components and mass content are: 76.5 parts of material body, 12.8 parts of high-ductility material, 5.2 parts of high-strength material and 0.5 part of unavoidable impurities.

[0052] The components and mass content of the main body of the material are: 93.5 parts of Al and 5 parts of Mg. The components and mass content of the high ductility material are: 33.55 parts of Mn, 8.2 parts of Bi, 10.6 parts of Ce, 17.8 parts of Cn and 15.5 parts of Mo. The components and mass content of the high-strength material are: 26.8 parts of Ca, 10.2 parts of Ni, 15.5 parts of Cu, 26.7 parts of Si and 8.2 parts of Sn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com