Method for toughening 3D printed concrete structure through high-ductility cement-based material

A cement-based material and concrete structure technology, which is applied in the processing of building materials, building construction, construction, etc., can solve the problem that woven mesh cannot be applied, carbon fiber cloth and fiber woven mesh cannot effectively adapt to the extrusion process, and layer-by-layer construction Process and other issues, to achieve the effect of low cost, fast construction speed and simple reinforcement process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

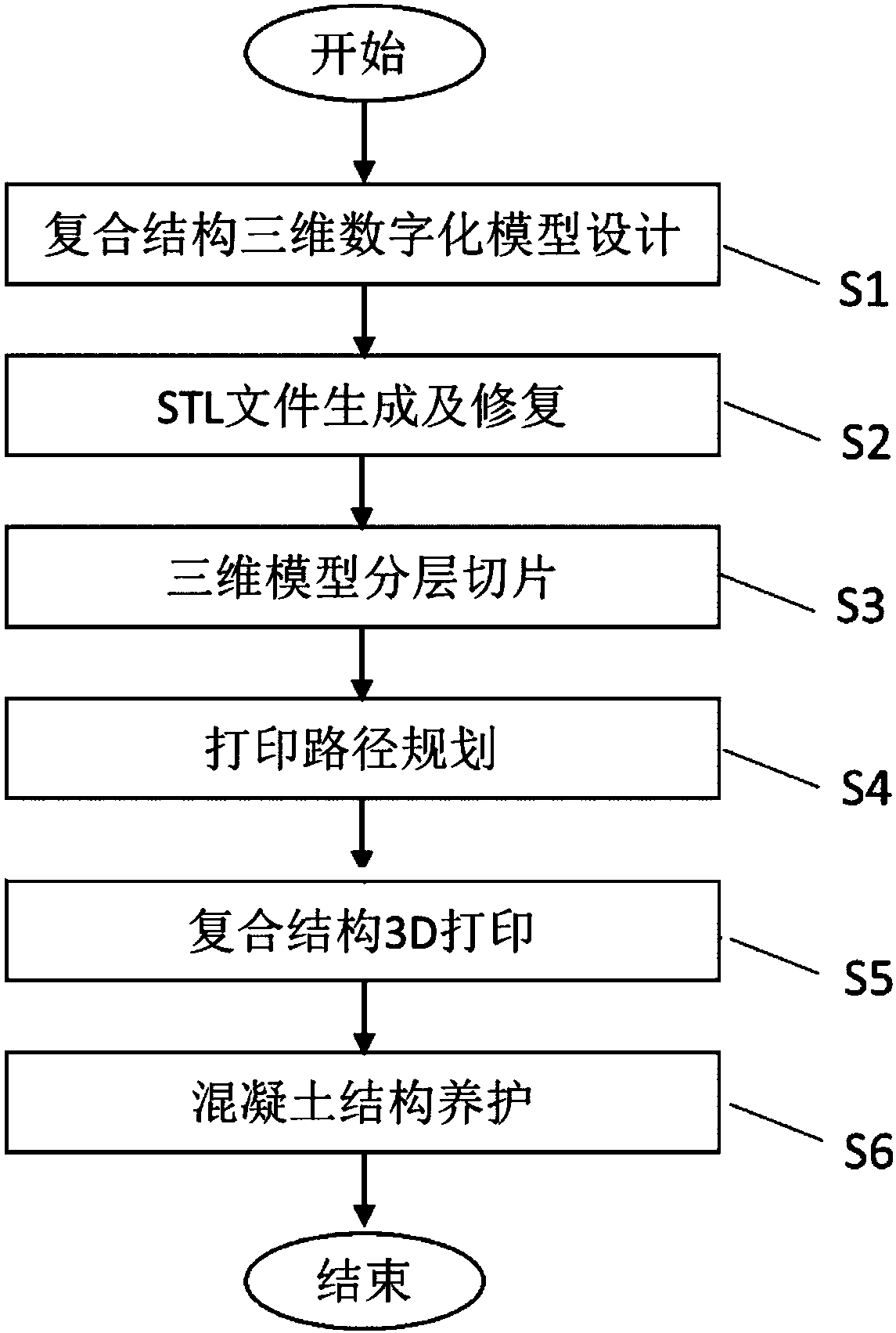

Method used

Image

Examples

preparation example Construction

[0045] The preparation method of the high ductility cement-based material comprises the following steps:

[0046] In terms of parts by weight, pour 0.8-1.2 parts of rapid hardening ordinary Portland cement, 0.96-1.44 parts of F-class fly ash and 0.64-0.96 parts of quartz sand into the mixer and stir for 2-3 minutes; Pour 2 / 3 of the mixture of 0.43 parts and 0.005-0.01 parts of water reducer into the mixer and stir for 5-6 minutes; then pour the remaining 1 / 3 of the mixture of water and water reducer into the mixer and stir for 2-3 Minutes; PVA fibers and basalt fibers are put into a mixer in turn and stirred to obtain the concrete.

[0047] When the above-mentioned high ductility cement-based material is pumped or mechanically transported into the print nozzle of the 3D printer, the outlet cross-sectional area of the print nozzle is set to 64-110mm 2 , the extrusion speed is set to 0.35-0.50m 3 / h, the horizontal printing speed is set to 280-310m / h.

[0048] The present i...

Embodiment 1

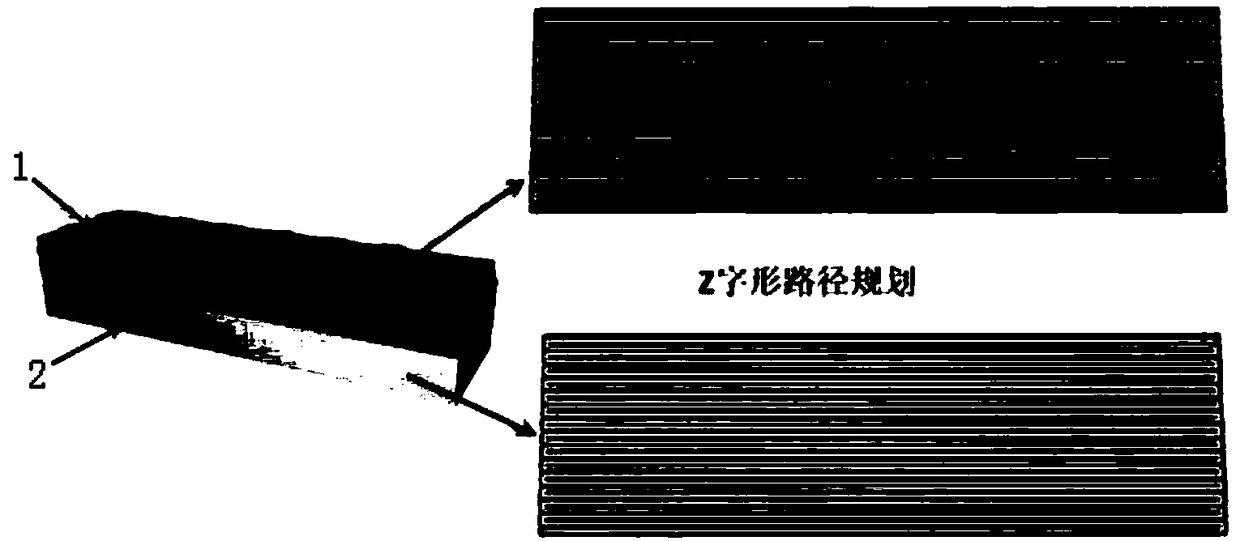

[0054] In this example, a composite beam structure is prepared by using a high-ductility cement-based material to toughen a 3D printed concrete structure. The composite beam structure to be printed in this example is a rectangular beam structure with a size of 150×150×700mm.

[0055] Preparation of ordinary concrete material 1: Pour 0.9 parts of rapid-hardening ordinary Portland cement 52.5R, 1.18 parts of F-grade fly ash, and 0.75 parts of quartz sand into an 80L planetary mixer and stir for 2 minutes; then add 0.32 parts of water and reduce Pour 2 / 3 of the mixture of 0.006 parts of water agent into the mixer and stir for 5 minutes; then pour the remaining 1 / 3 of the mixture of water and water reducer into the mixer and stir for 2 minutes to obtain 3D printed concrete;

[0056] Preparation of high-ductility cement-based material 2: Pour 0.9 parts of rapid-hardening ordinary Portland cement 52.5R, 1.18 parts of F-class fly ash, and 0.75 parts of quartz sand into an 80L planetar...

Embodiment 2

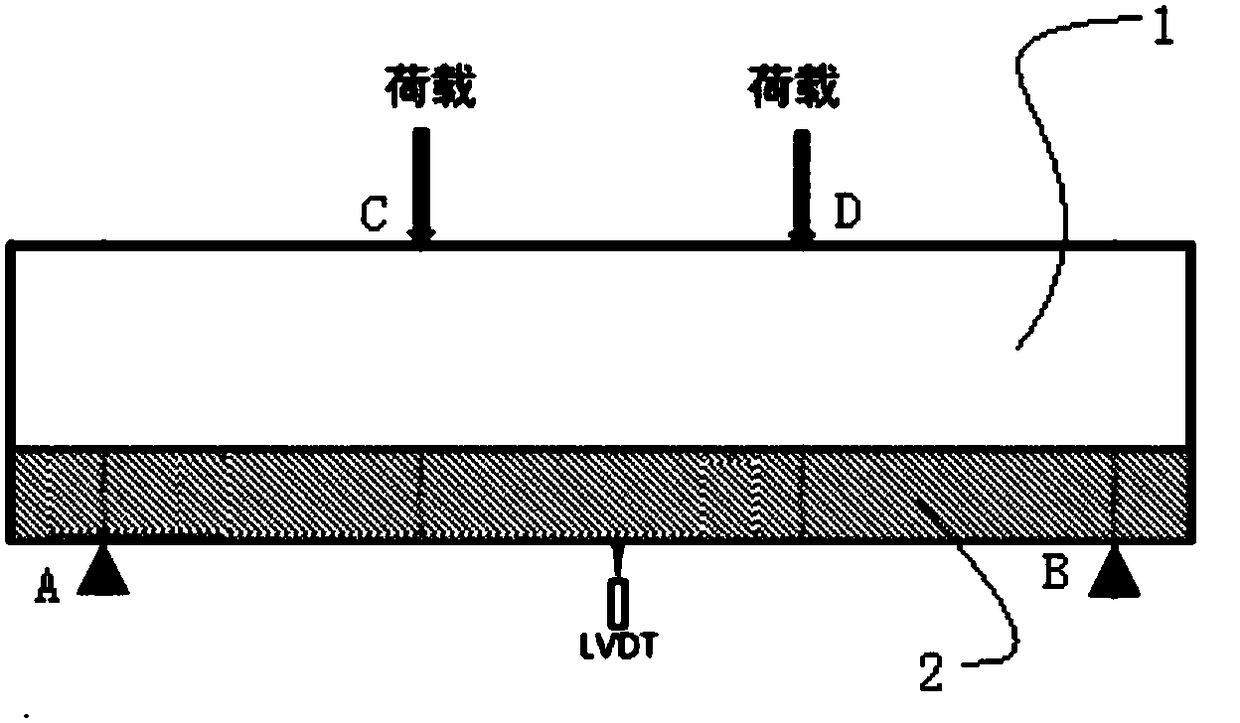

[0067] In this example, except that the layer thickness of the high-ductility cement-based material is changed to 60 mm, and the thickness of the plain concrete layer is changed to 90 mm, the other manufacturing processes and material parameters are the same as those in Example 1, which is equivalent to the fiber cement-based material. 40% of the overall structure. With reference to "Standard for Test Methods of Mechanical Properties of Ordinary Concrete" (GB / T50081-2002), the concrete beam of this embodiment is tested for four-point bending mechanical properties. The loading scheme is as follows figure 2 shown. The bending stress and mid-span deflection curves obtained during the experiment are plotted in Figure 4 , the curve strongly demonstrates that this embodiment adopts the method to toughen the plain concrete, and the toughened composite beam has the characteristics of high ductility. Test results: The peak load is 39.0kN, the crack initiation deflection is 0.642mm,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com