Method of magnetically processing an iron-carbon alloy

a technology of iron-carbon alloys and magnetic processing, which is applied in the field of processing of iron-carbon alloys, can solve the problems of excessive time taken for bainite transformation, and achieve the effects of improving ductility and strength, improving mechanical properties, and high field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

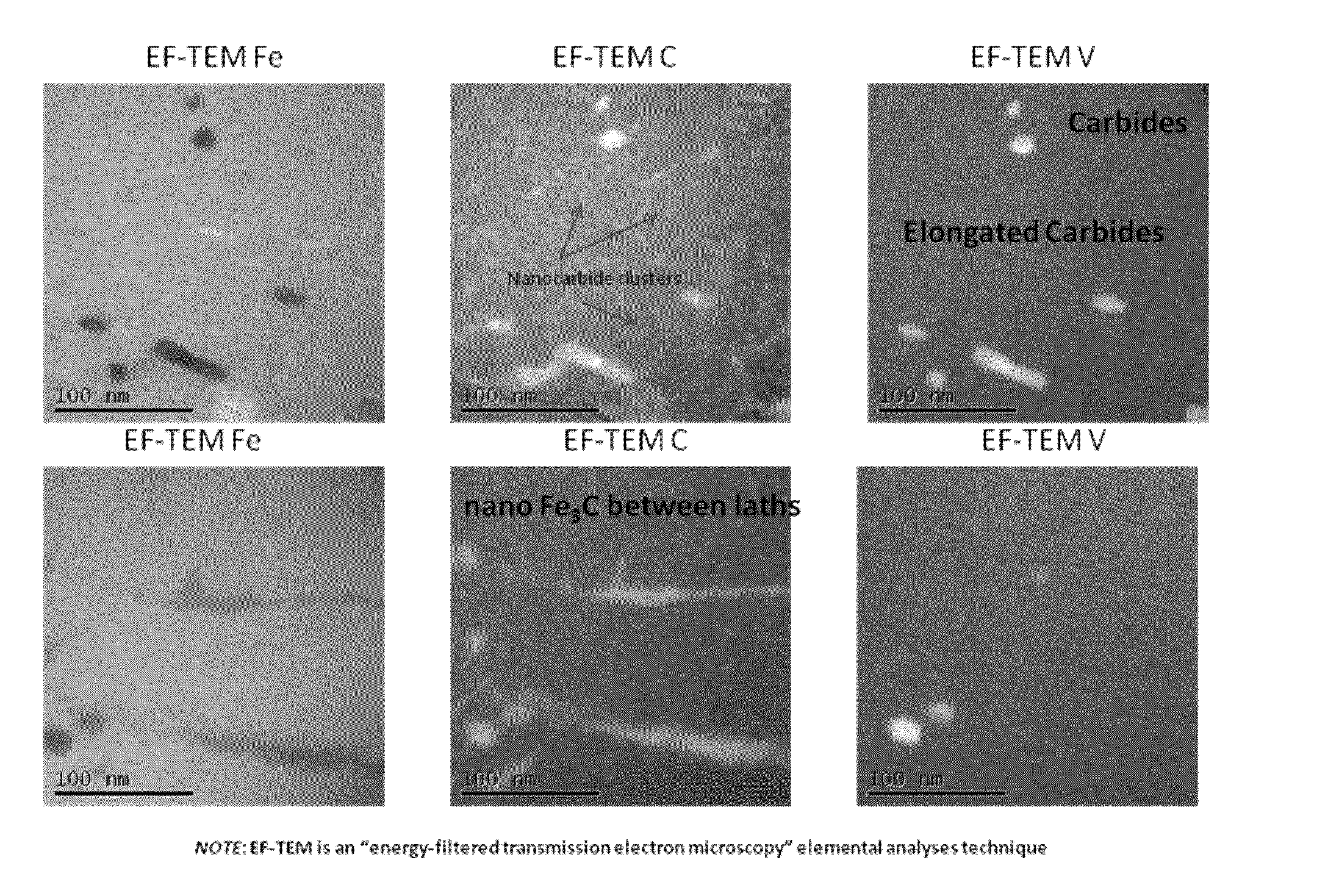

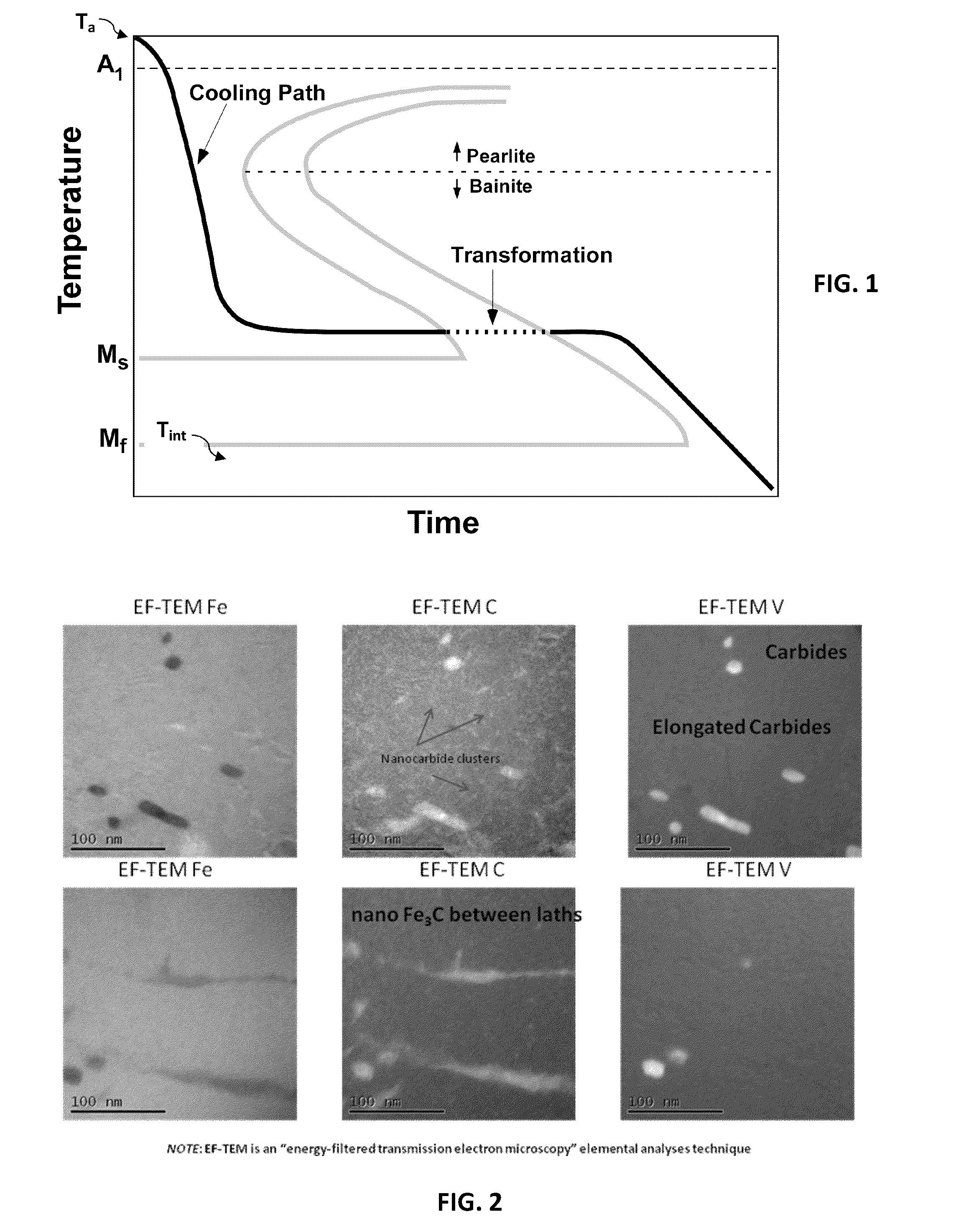

Image

Examples

example 1

[0026]The magnetic processing method described above has been applied to low carbon, low alloy steel specimens prepared by Carpenter Technology Corporation (Wyomissing, Pa.). The chemistry of the tested alloy, where the balance is iron, is shown in Table 2.

TABLE 2Experimental Alloy CompositionElementCMnSiPSCrNiCuVTiAlN [ppm]O [ppm]wt. %0.360.780.941.263.810.520.30.004

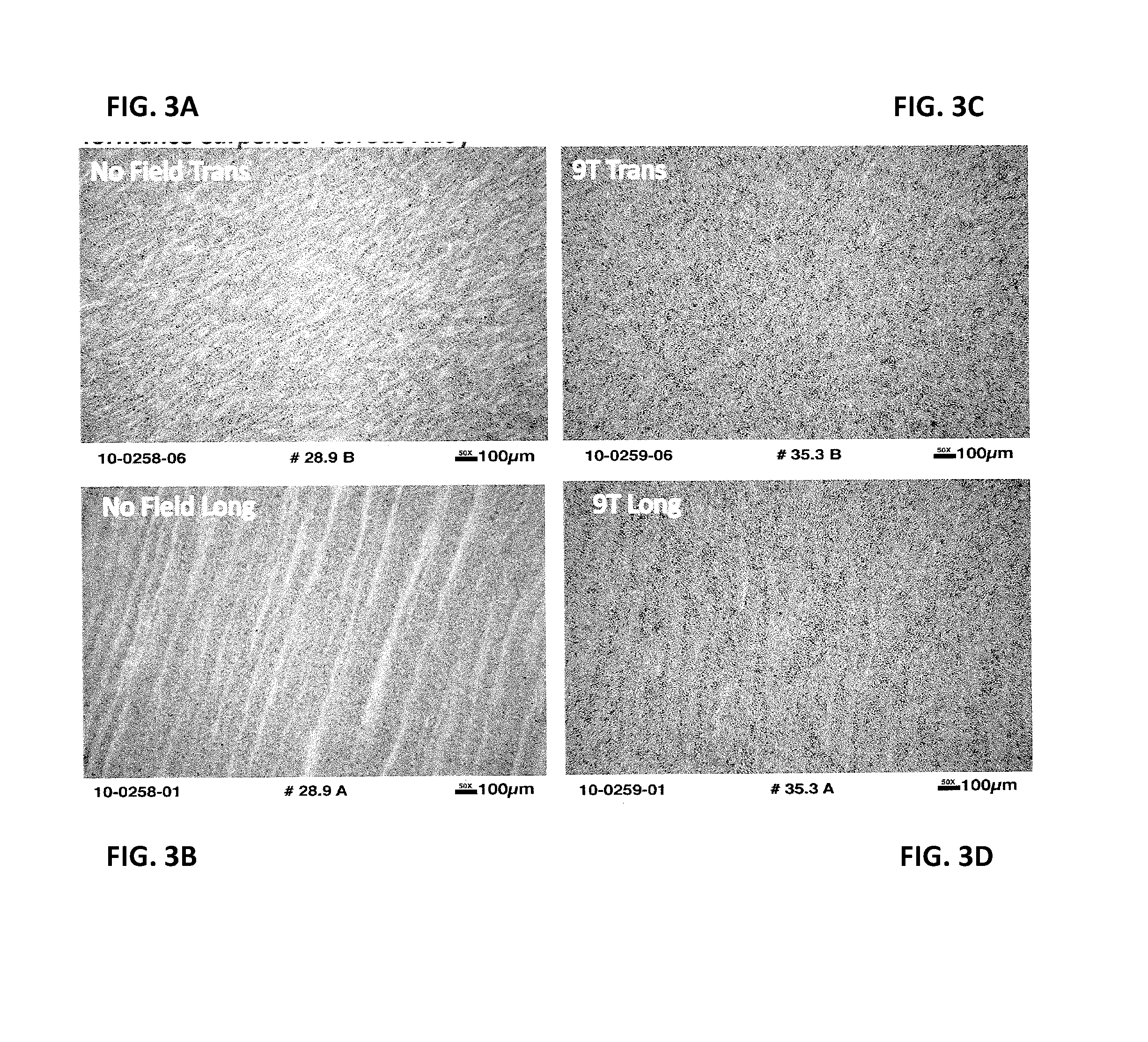

[0027]In a series of experiments carried out using this alloy, the following experimental conditions were employed to compare the microstructure and properties when a high magnetic field was applied during the austempering process versus a reference no-field condition.

[0028]For the thermomagnetic processing runs, specimens were processed as follows prior to carrying out tensile and Charpy impact tests:[0029]Austenitized at 885° C. under a 9T field for 30 min;[0030]Helium-gas-quenched at 90 psi to 250° C.;[0031]Held at 250° C. for 8 hrs under a 9T magnetic field; and[0032]Helium-gas-quenched to room temperature.

[0033]For...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| field strength magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com