Damper

A technology of dampers and damping pistons, which is applied in the field of hydraulic dampers, can solve problems such as inconstant damping force, changes in damping force, and influence on damping and buffering effects, and achieve the effect of ensuring damping force and preventing changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

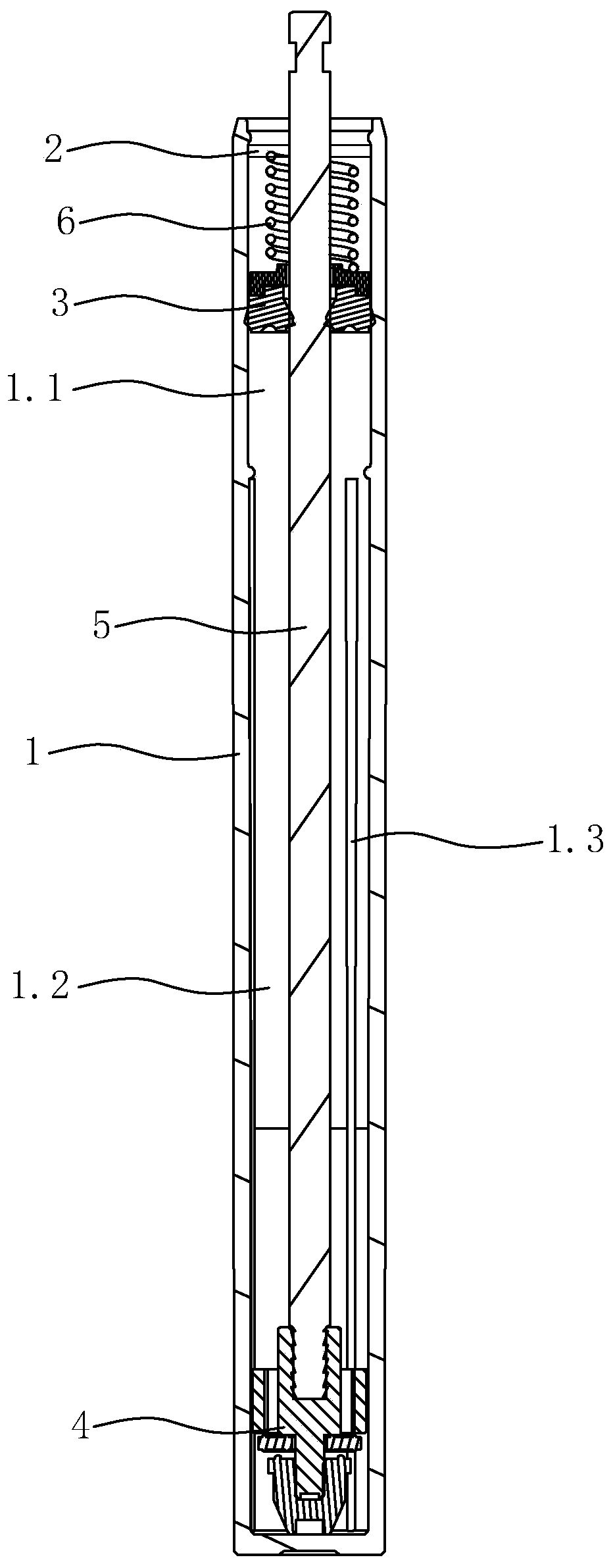

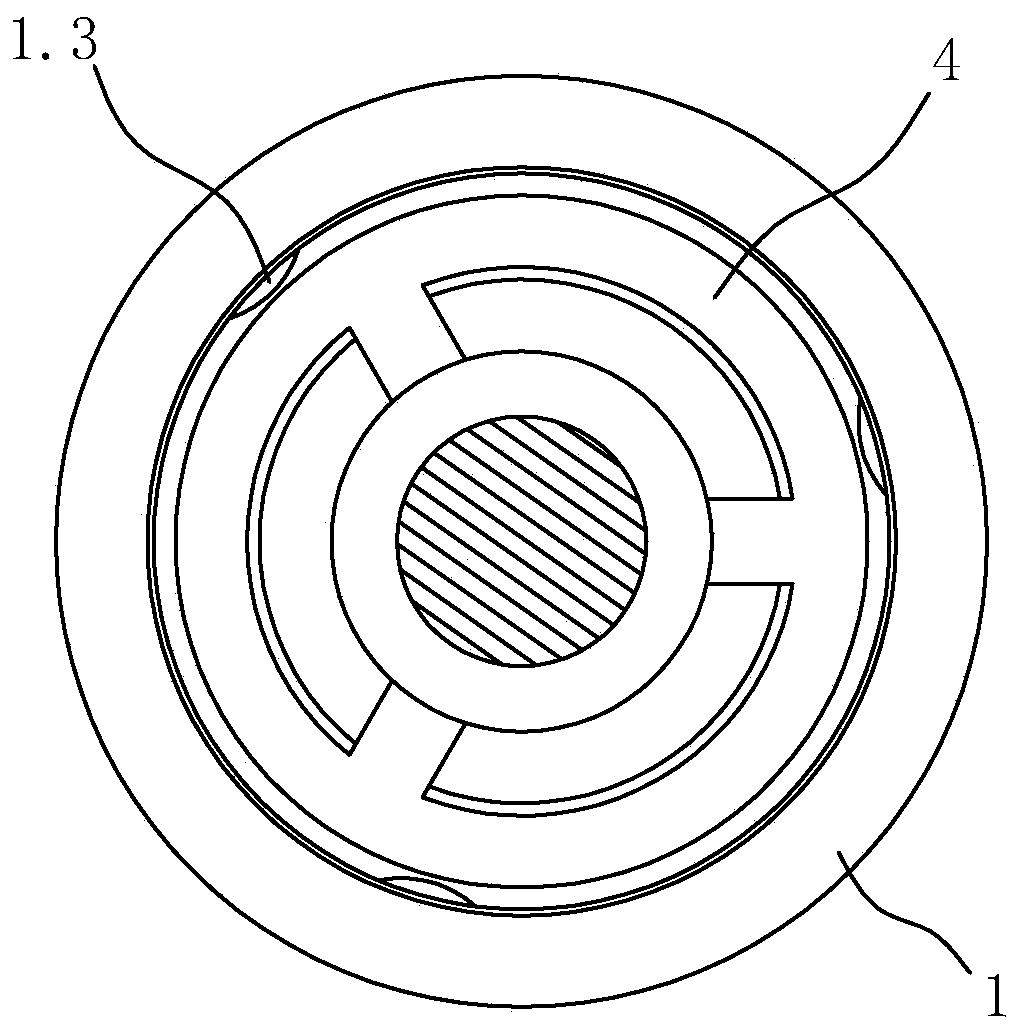

[0009] Such as figure 1 , 2 As shown, a damper includes a cylinder barrel 1 with a liquid storage cylinder section 1.1 and a hydraulic cylinder section 1.2, a plug cover 2 fixed on the mouth of the cylinder barrel 1, a sealing ring plug 3 on the liquid storage cylinder section 1.1, and a plug on the hydraulic cylinder section 1.1. The damping piston 4 of the hydraulic cylinder section 1.2, the piston rod 5 that is fixed to the damping piston 4 and slides through the sealing ring plug 3 and passes through the plug cover 2, and the spring 6 that keeps the sealing ring plug 3 sliding towards the hydraulic cylinder section 1.2 . In the present invention, the inner peripheral wall of the hydraulic cylinder section 1.2 of the cylinder 1 forms several axially extending ribs 1.3.

[0010] The cylinder barrel 1 is divided into two sections by a retaining ring 1.3, the inner section is a hydraulic cylinder 1.2, and the outer section is a fluid storage cylinder 1.1. The sealing ring p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com