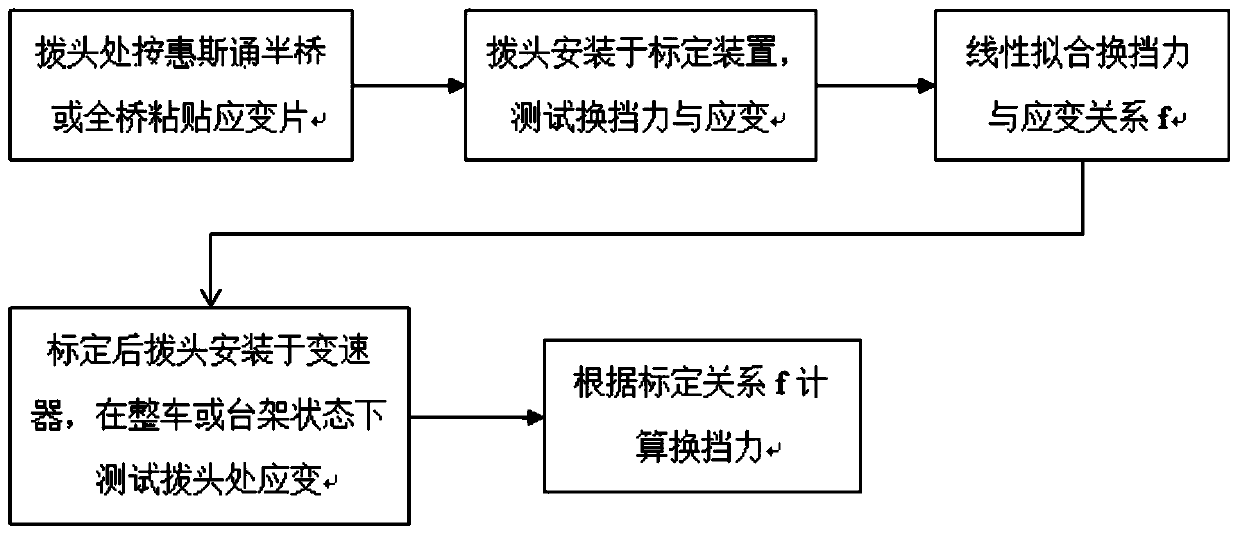

System and method for testing shifting force at shifting block in working state of a transmission

A working state and testing system technology, which is applied to the reliability and shifting performance analysis of the transmission shift mechanism, and the test system field of the shifting force at the shift head under the transmission working state. It can solve the problem that the test system has not yet appeared and cannot be measured by sensors. Shift force and other issues, to achieve accurate and reliable test results, compact and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

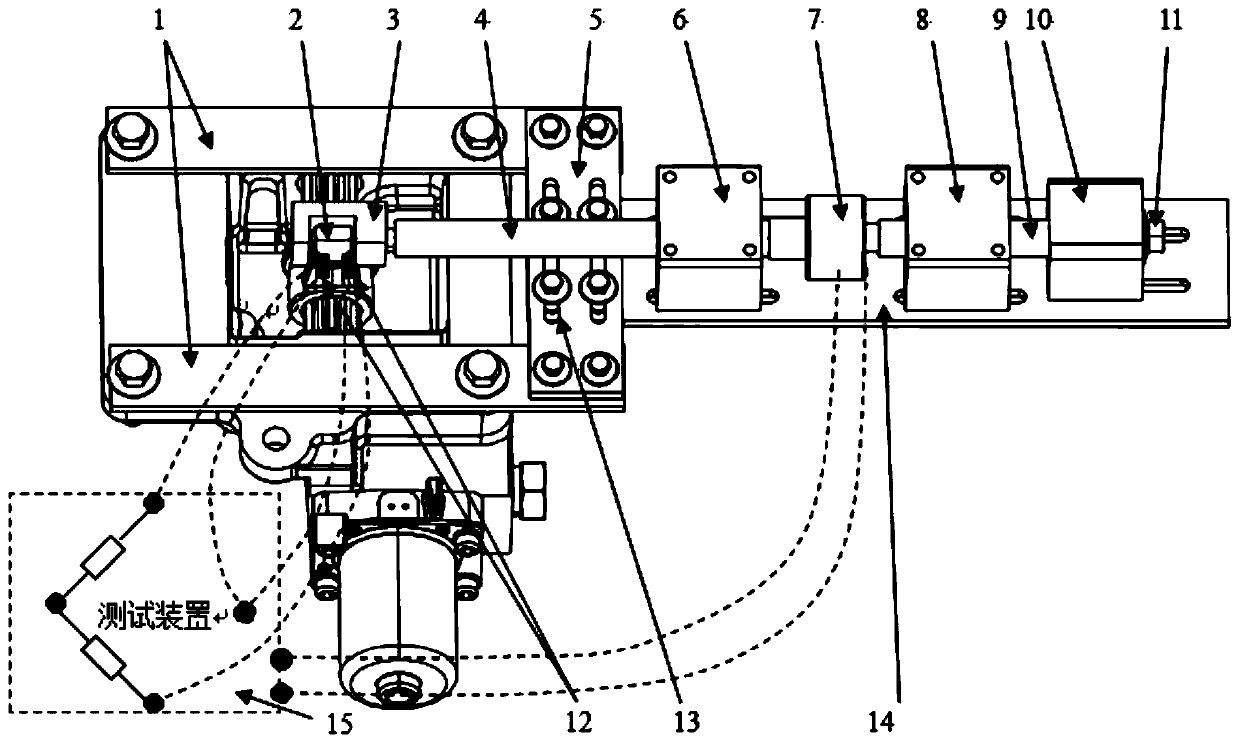

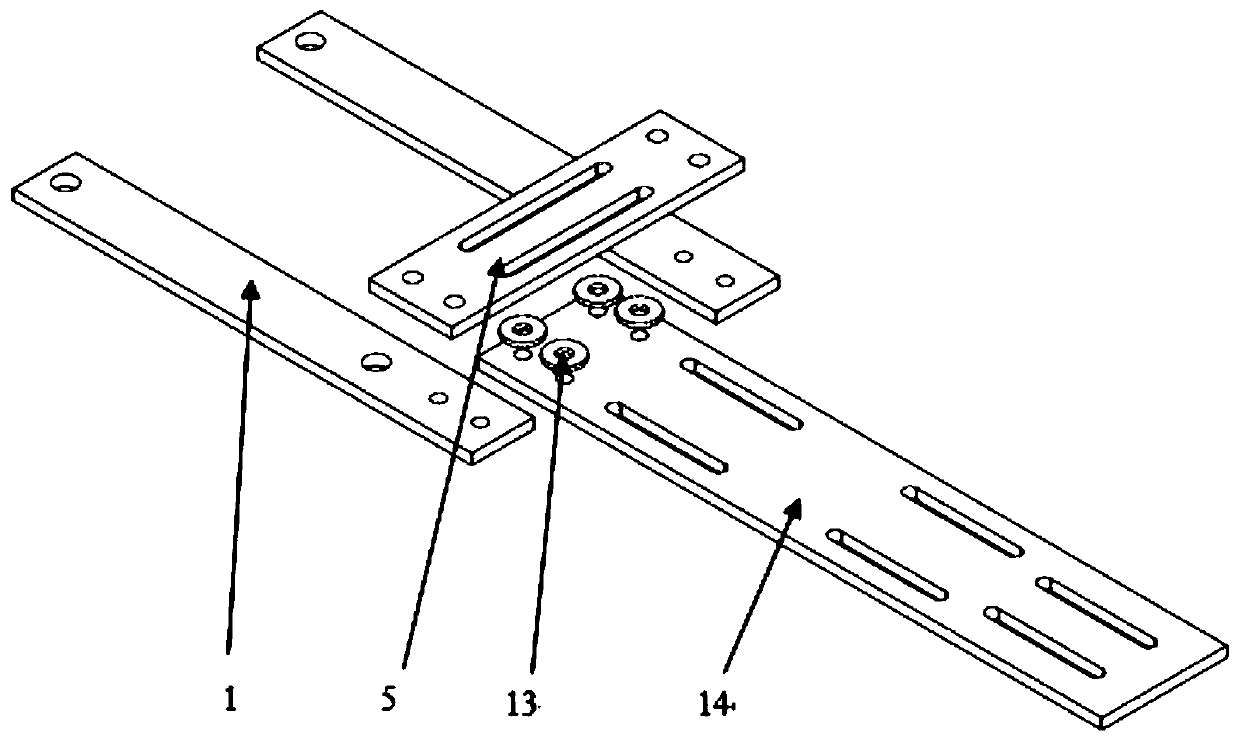

[0037] Paste the strain gauges 12 on the two sides of the toggle head where the tensile stress and compressive stress are relatively large. Taking the Wheatstone half-bridge wiring method as an example, the bridge is connected to the test device 15 . The connecting plate 1 is installed on the shift top cover through bolts, and the transverse adjustment plate 5 is installed on the connecting plate 1 through bolts. Select the height adjustment gasket 13 of appropriate thickness, and connect the longitudinal adjustment plate 14, the height adjustment gasket 13 and the horizontal adjustment plate 5 through bolts without tightening. The front end power transmission shaft 4 is installed in the front end linear bearing 6, the rear end power transmission shaft 9 is installed in the rear end linear bearing 8, the limit bolt 11 passes through the inner hole of the fixed block 10, and the dial block 3 is threaded. , front end force transmission shaft 4, tension pressure sensor 7, rear en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com