New energy automobile electric control system fault prediction method based on working condition data

A new energy vehicle, electronic control system technology, applied in general control systems, control/regulation systems, testing/monitoring control systems, etc., can solve problems such as battery acupuncture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Embodiments of the present invention will be described in detail below. It should be emphasized that the following description is exemplary only, and is not intended to limit the scope of the invention and its application.

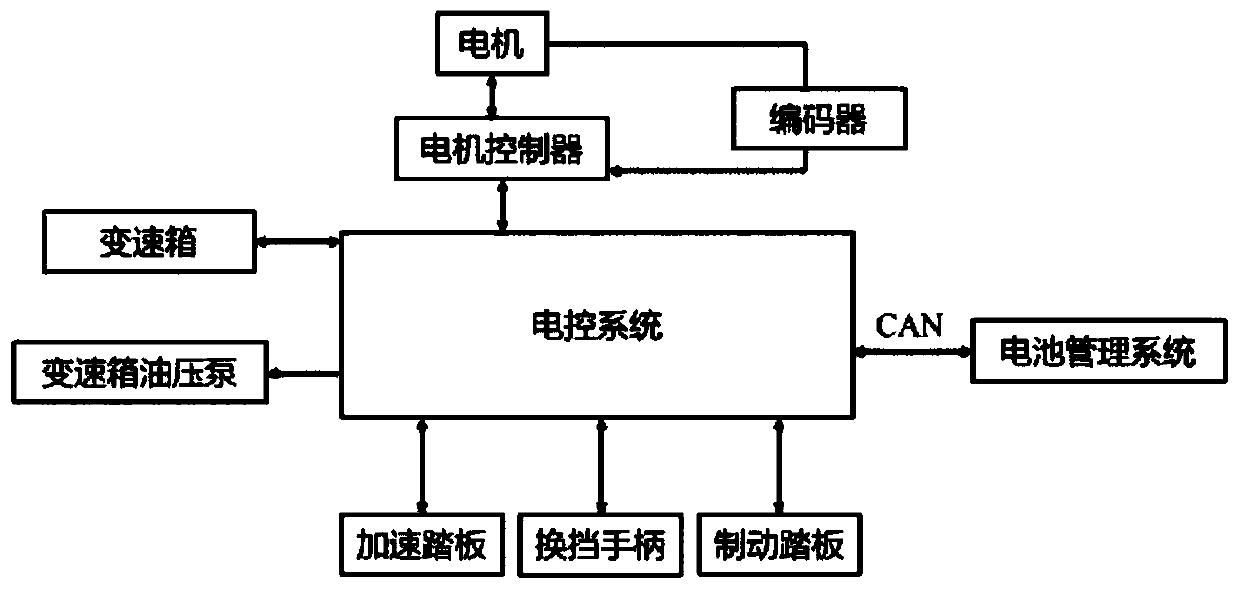

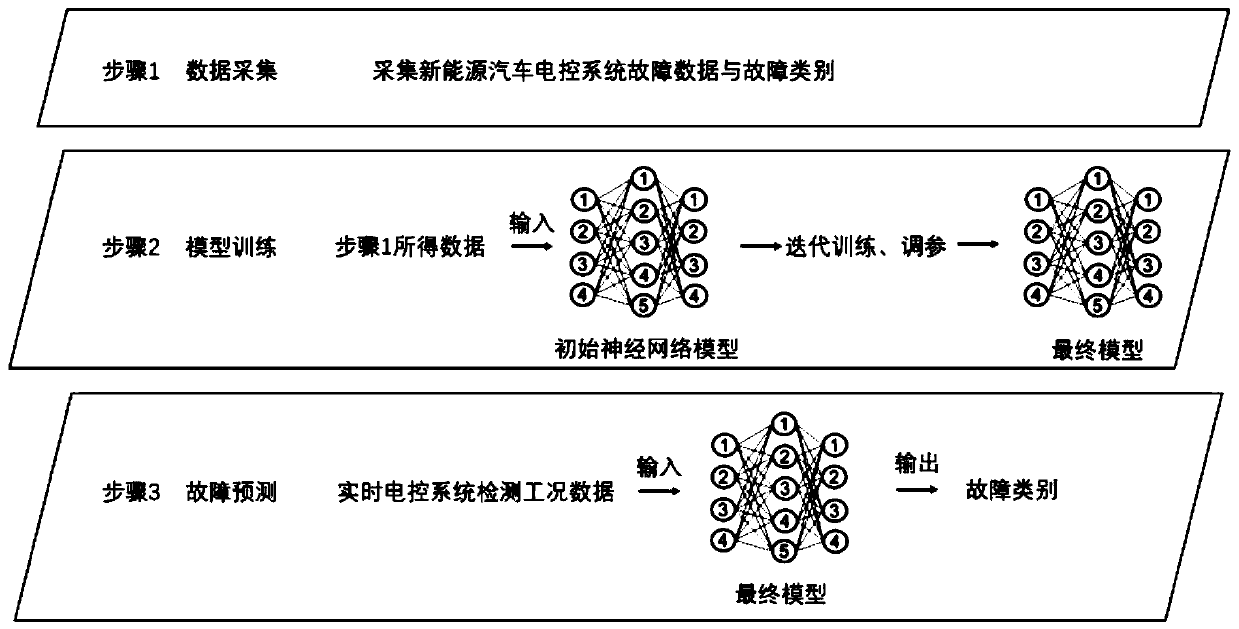

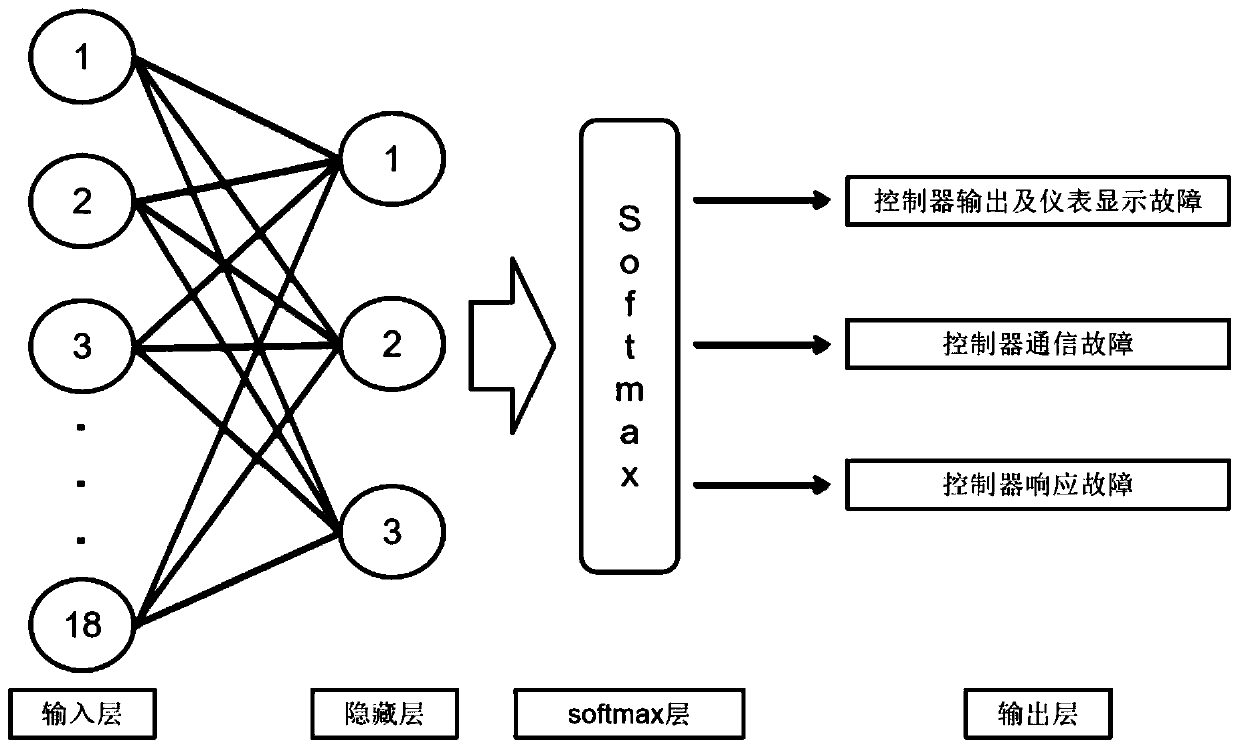

[0029] The present invention provides a fault prediction method for an electronic control system of a new energy vehicle based on working condition data, the process of which is as follows: figure 1 Based on the collection of fault data and fault samples of the electronic control system of new energy vehicles, such as the data of 18 fields such as controller output deviation, controller response data, instrument display deviation, etc., these data are used as new energy vehicle fault prediction. The support of the database, as a learning sample, combined with the neural network prediction method, establishes a neural network-based electronic control system fault prediction model. The model includes four layers, namely the input layer (18 nodes), th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com