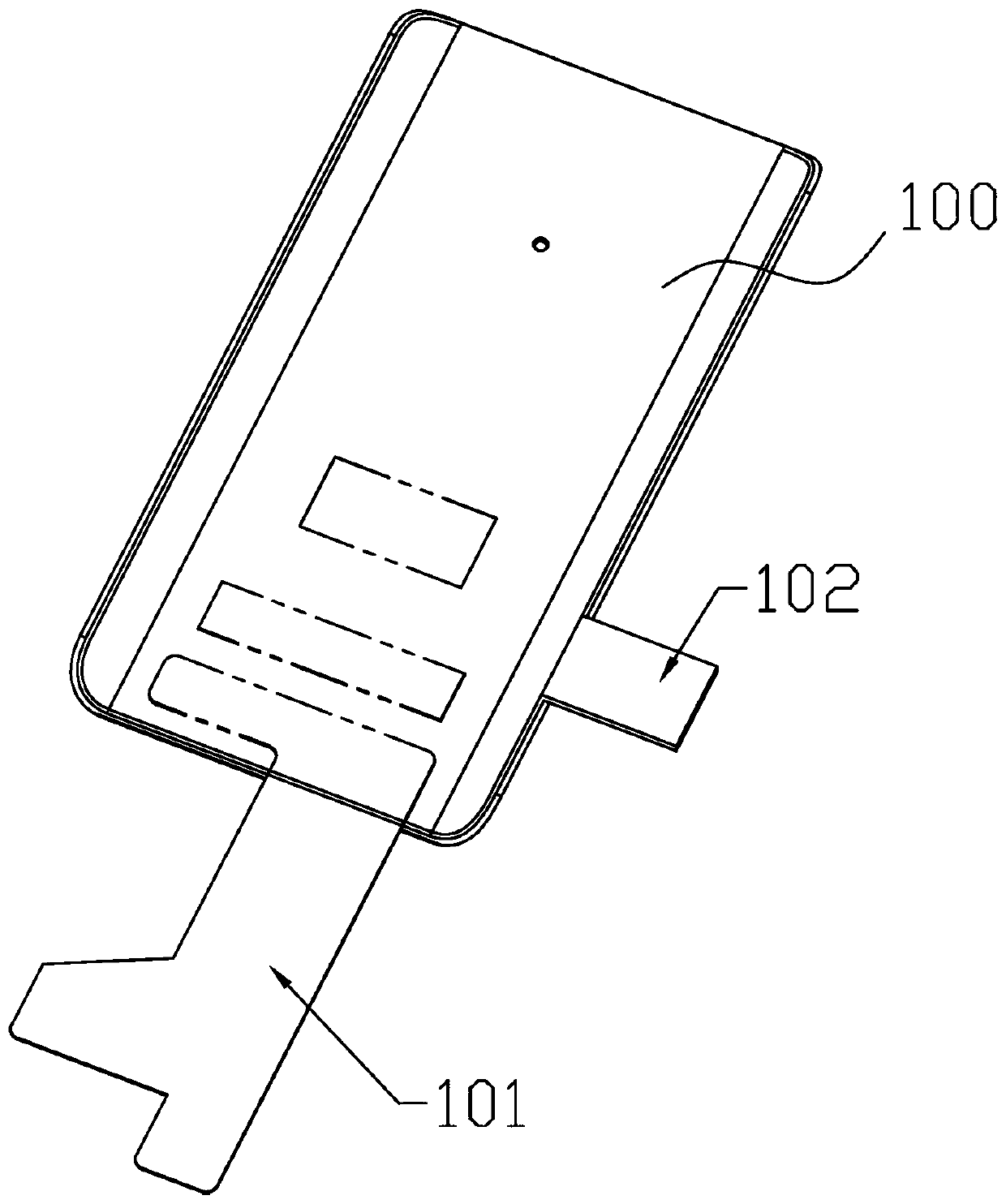

OLED FPC attaching device

A technology for laminating equipment and conveying devices, which is applied to conveyor objects, electrical components, electric solid devices, etc., can solve the problems of low lamination accuracy, low production efficiency, waste of labor, etc., to improve work efficiency and processing accuracy. High, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with accompanying drawing:

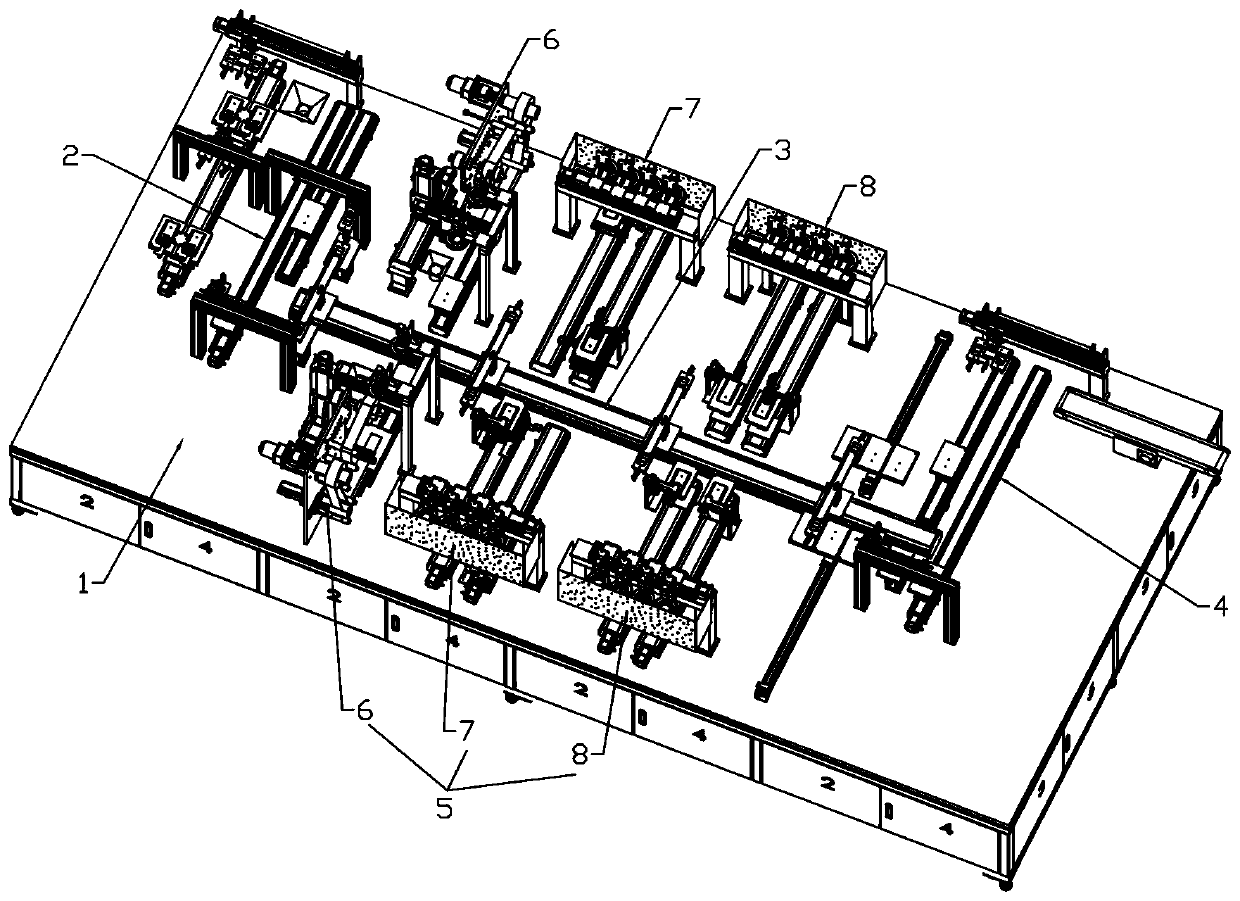

[0031] like Figure 1-8 As shown, an OLED FPC bonding equipment includes a workbench 1, a loading mechanism 2, a conveying mechanism 3, and an unloading mechanism 4 installed on the workbench 1 from left to right, and two groups are installed before and after the conveying mechanism 3 A processing module 5 with the same structure on both sides and symmetrically arranged; the processing module 5 includes a gluing mechanism 6, a folding mechanism 7 and a pressure maintaining mechanism 8 distributed sequentially from left to right;

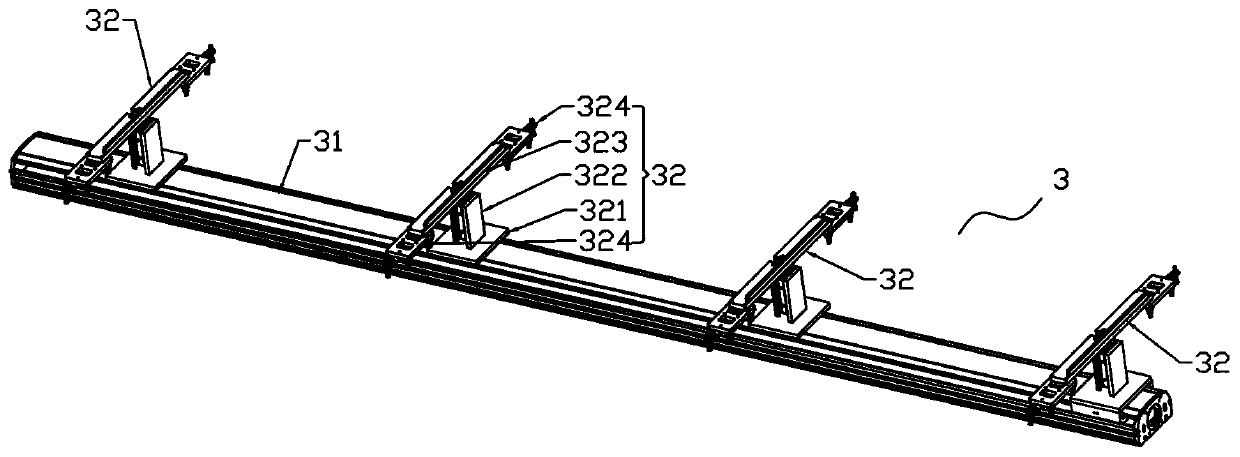

[0032]The conveying mechanism 3 includes a first X-direction linear conveying device 31 and at least one set of conveying manipulators 32 installed on the first X-direction linear conveying device 31; the conveying manipulator 32 includes a sliding seat 3201, a first cylinder 3202, a connection plate 323 and two groups of first adsorption compone...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap