Electric tool

A technology of electric tools and tools, applied in the direction of striking tools, manufacturing tools, portable impact tools, etc., can solve the problems of reduced work efficiency and increased time lag, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the drawings. In addition, the same reference numerals are attached to the same or equivalent constituent elements, members, processes, etc. shown in each drawing, and overlapping descriptions are appropriately omitted. Furthermore, the embodiments are illustrative rather than restrictive, and all the features described in the embodiments or combinations thereof are not necessarily the essence of the invention.

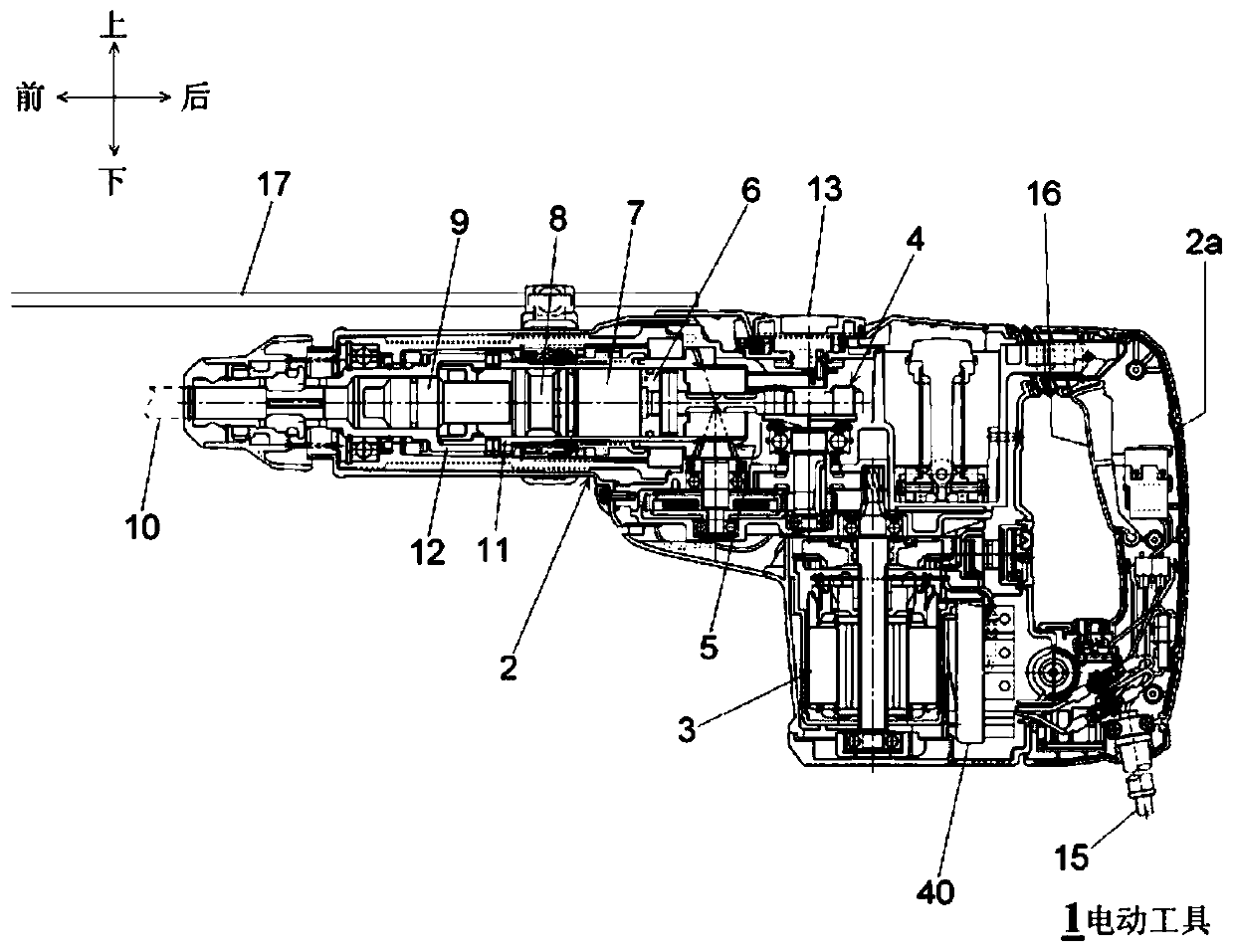

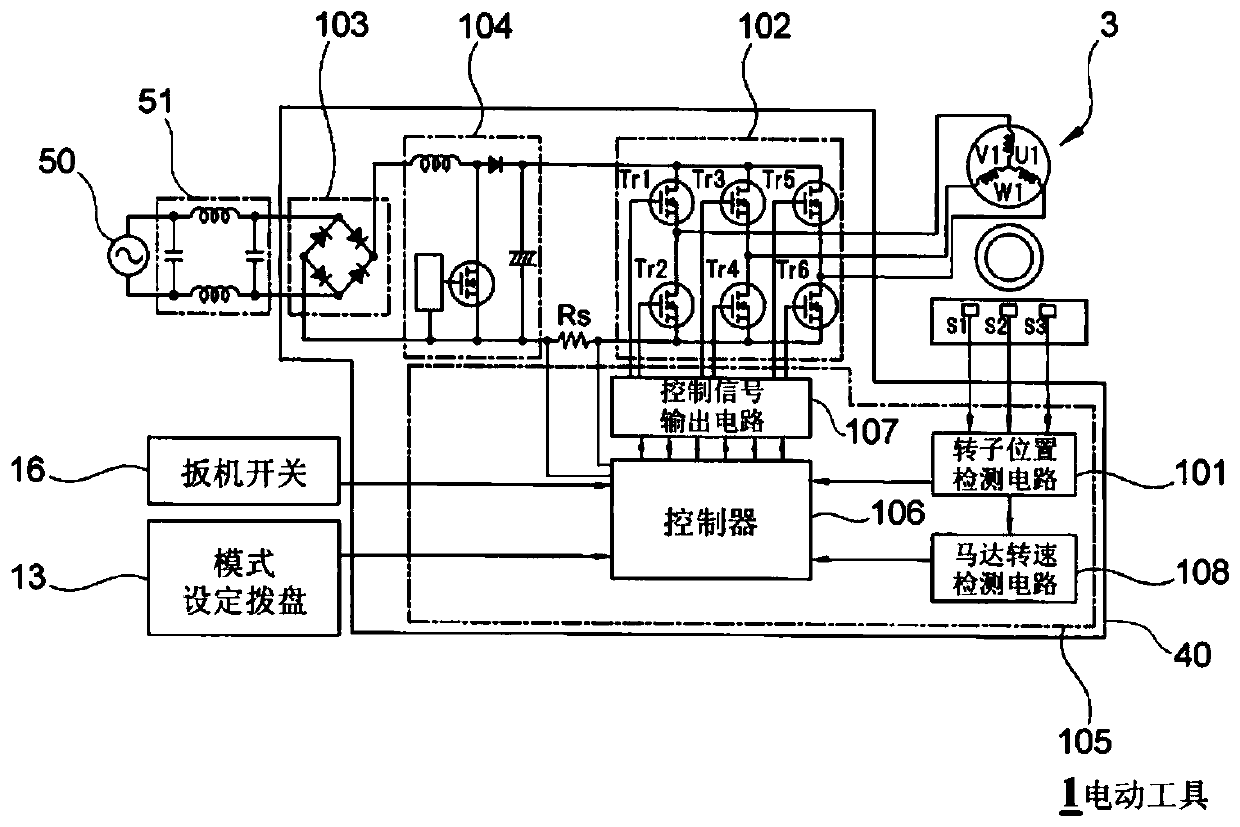

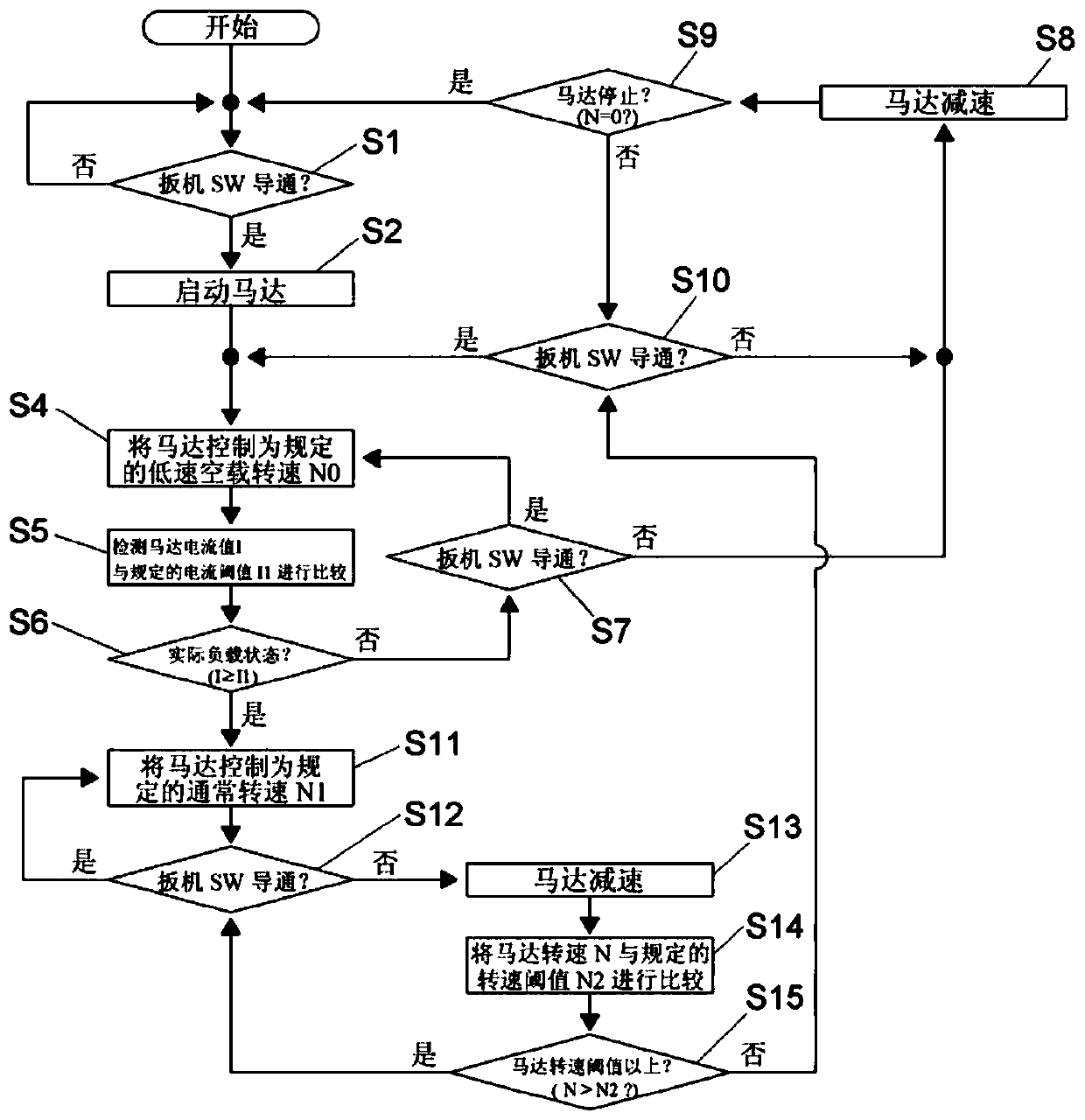

[0041] figure 1 It is a side sectional view of the electric power tool 1 which concerns on embodiment of this invention. pass figure 1 to define the front-back and up-down directions. The electric tool 1 is a percussion drill (percussion machine), and by applying rotational force and impact force to the tip tool 10, it is possible to perform chiseling, drilling, and crushing on workpieces such as concrete and stone. In the electric power tool 1 , the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com