Crawling arc welding robot and failure detection method and device of crawling arc welding robot

A fault detection and robot technology, applied in arc welding equipment, manipulators, welding equipment, etc., can solve problems such as inability to self-check, and achieve the effect of improving user experience, meeting user needs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

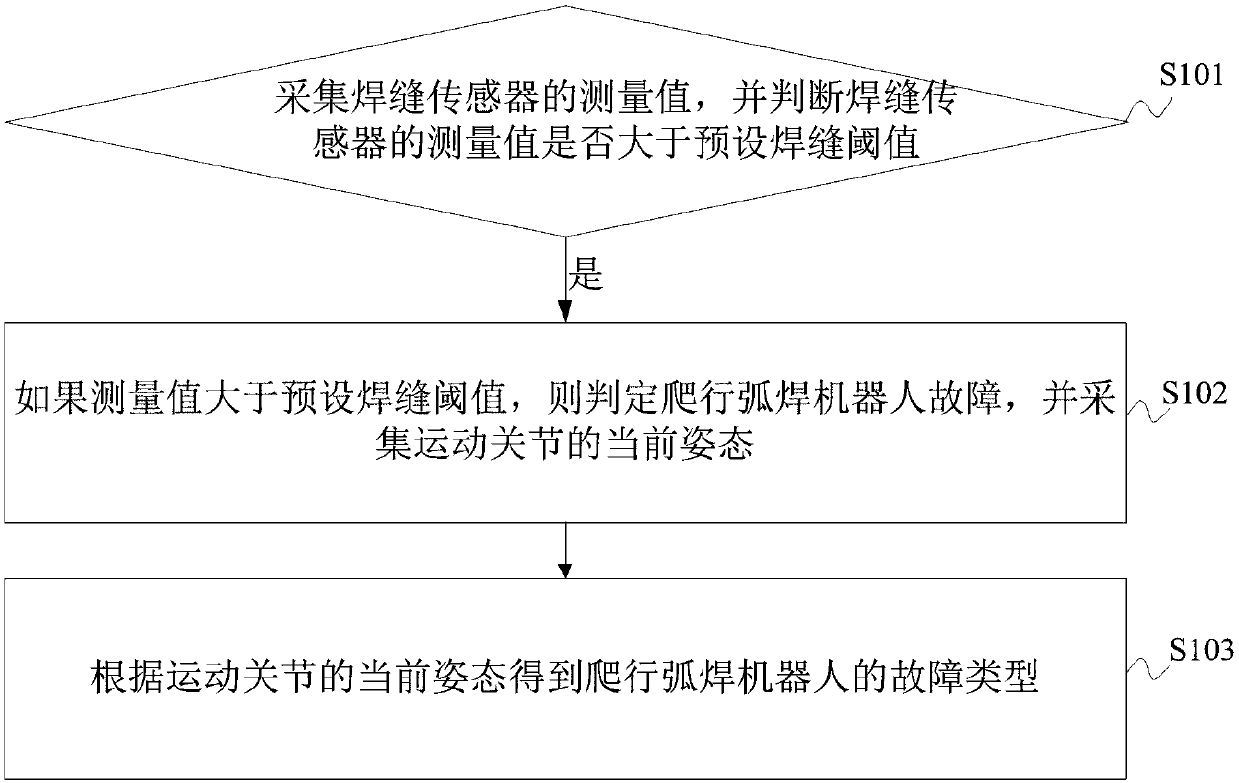

[0023] According to an embodiment of the present invention, an embodiment of a fault detection method for a crawling arc welding robot is provided. It should be noted that the steps shown in the flow chart of the accompanying drawings can be implemented in a computer system such as a set of computer-executable instructions and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0024] figure 1 It is a flowchart of a fault detection method for a crawling arc welding robot according to an embodiment of the present invention.

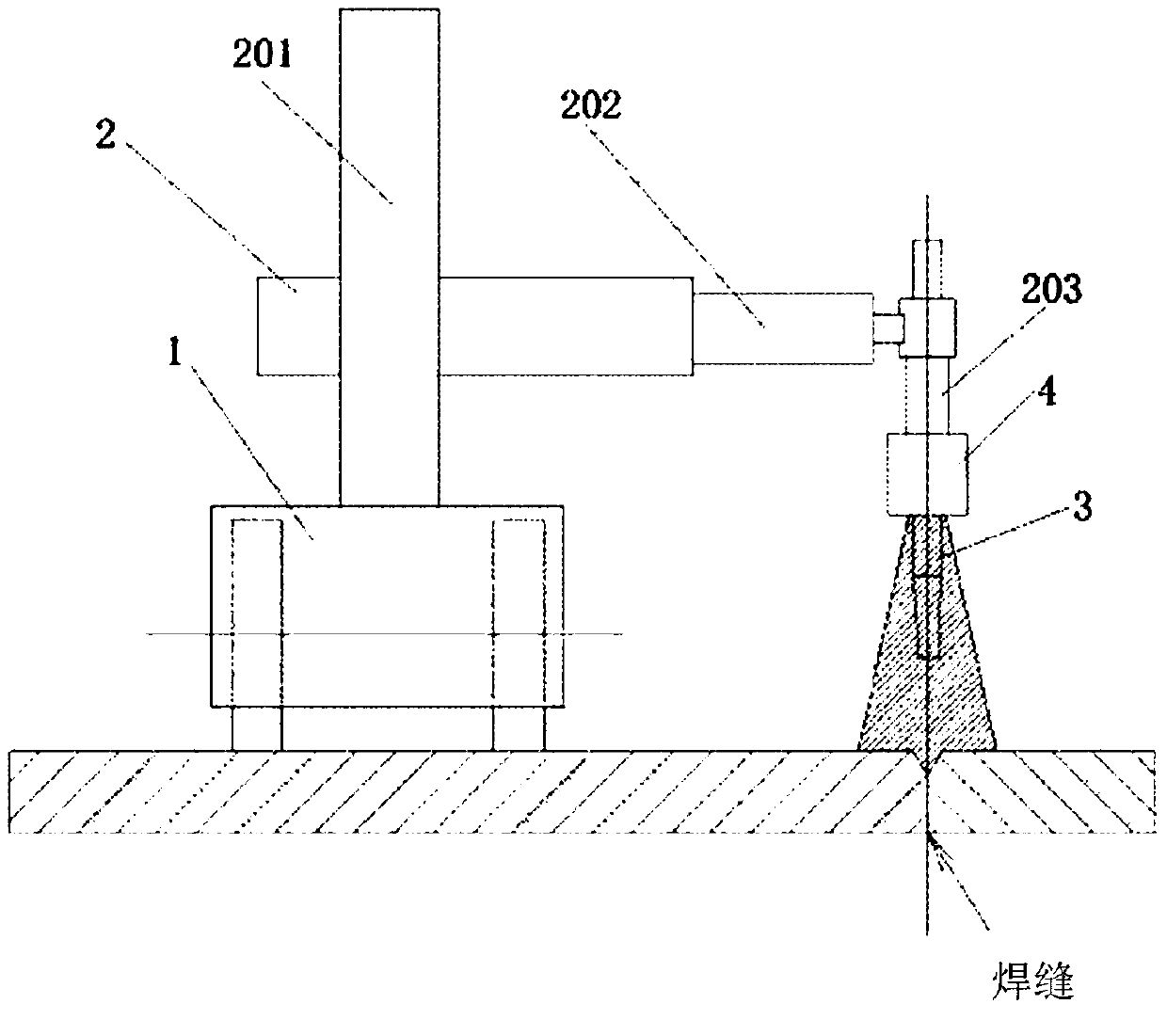

[0025] Such as figure 2 As shown, the structure of the crawling arc welding robot involved in the embodiment of the present invention includes: a walking trolley 1, a mechanical arm 2, a welding torch 3, a seam tracking sensor 4, a lifting joint 201, a telescopic joint 202 for horizontal adjustment, and an adjustment seam tracking se...

Embodiment 2

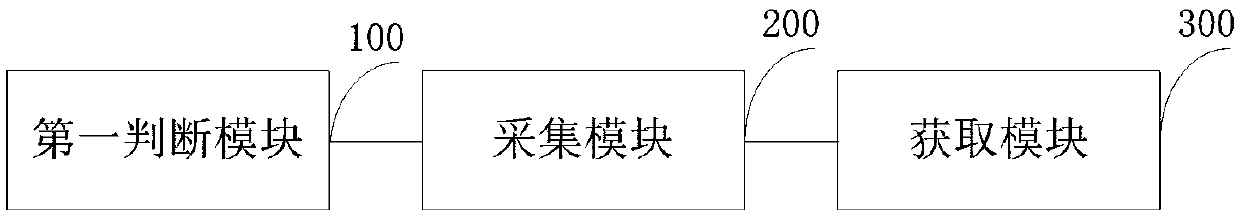

[0044] According to an embodiment of the present invention, an embodiment of a fault detection device for a crawling arc welding robot is also provided.

[0045] image 3 is a structural schematic diagram of a fault detection device for a crawling arc welding robot according to an embodiment of the present invention. Such as image 3 As shown, the device includes: a first judgment module 100 , a collection module 200 and an acquisition module 300 .

[0046] Wherein, the first judging module 100 is used for collecting the measured value of the weld seam sensor, and judging whether the measured value of the weld seam sensor is greater than a preset weld seam threshold. The collection module 200 is used to determine the failure of the crawling arc welding robot and collect the current posture of the kinematic joint when the measured value is greater than the preset weld threshold. The obtaining module 300 is used to obtain the fault type of the crawling arc welding robot accor...

Embodiment 3

[0053] According to an embodiment of the present invention, a crawling arc welding robot is also provided, which includes the above-mentioned fault detection device for a crawling arc welding robot.

[0054] According to the crawling arc welding robot proposed in the embodiment of the present invention, the above-mentioned fault detection device of the crawling arc welding robot solves the technical problem that the crawling arc welding robot cannot self-check after a fault in the prior art, thereby improving user experience and satisfying users demand and effectively improve production efficiency.

[0055] The serial numbers of the above embodiments of the present invention are for description only, and do not represent the advantages and disadvantages of the embodiments.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com