A Cylindrical Grinding Device Applicable to Shafts with Different Diameters

A technology of cylindrical grinding and different diameters, which is applied in the direction of grinding devices, grinding drive devices, grinding machine tools, etc., which can solve the problem that the center distance of the supporting wheel and the height of the supporting wheel cannot be adjusted and moved, reduce the grinding accuracy of the device, and reduce the application of the grinding machine. In order to improve the applicability and work stability, improve the grinding accuracy and ensure the positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments, but it is not a basis for limiting the present invention.

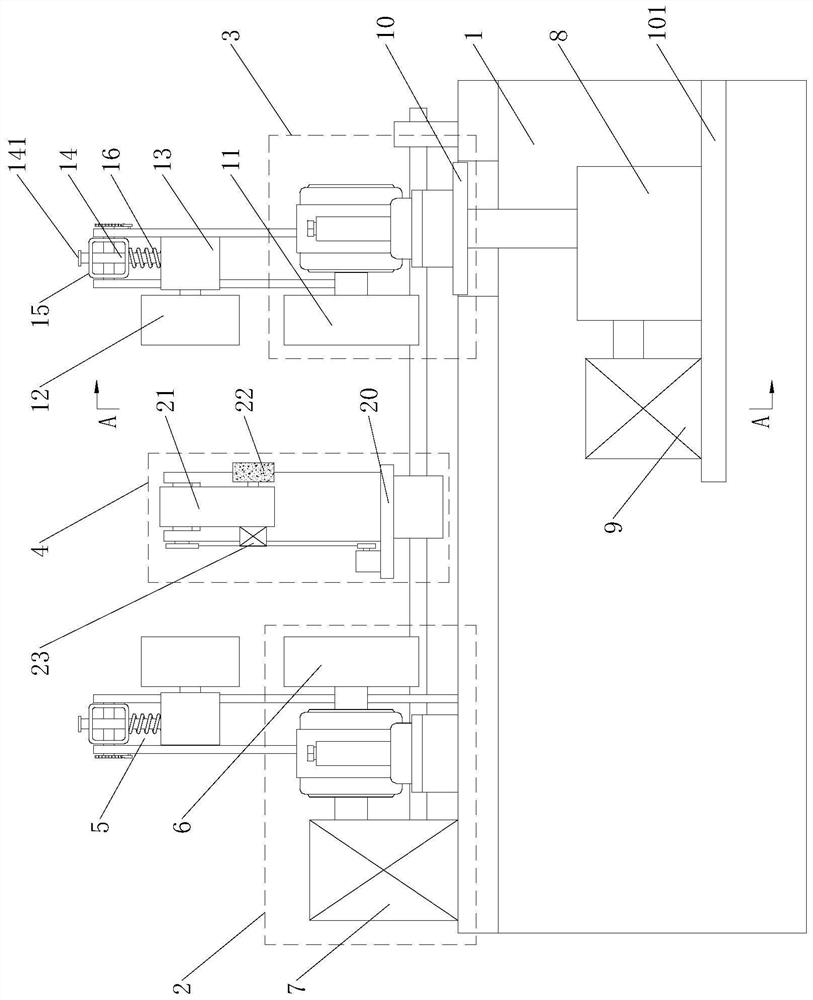

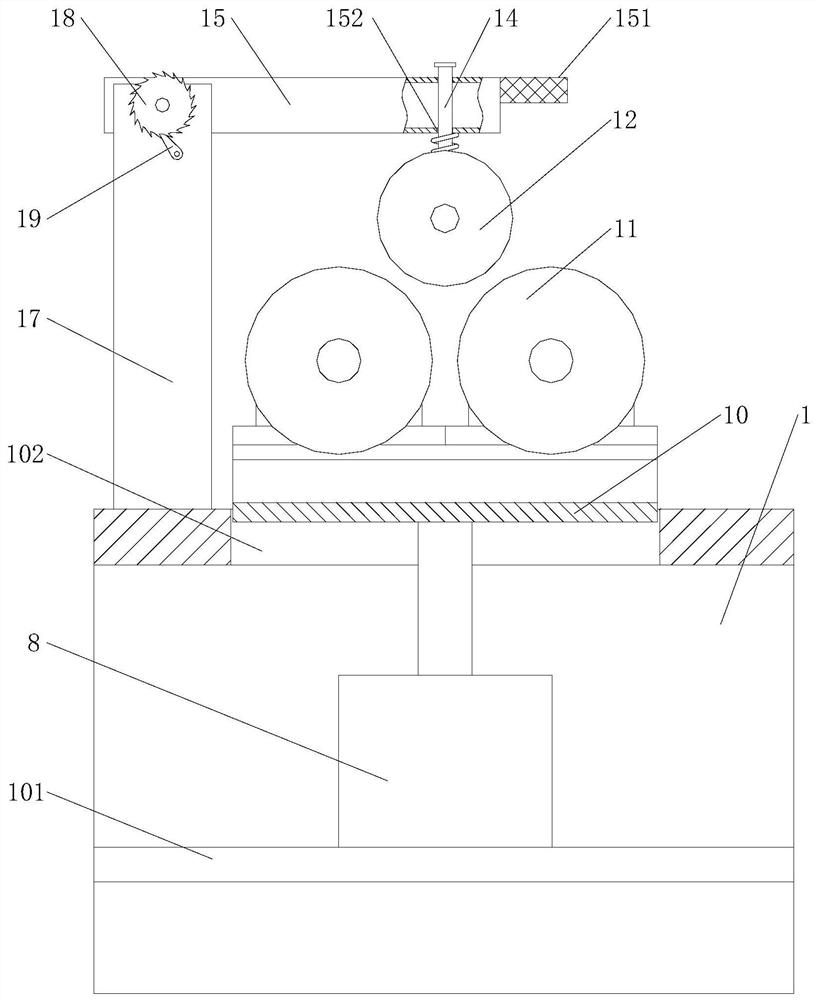

[0013] Examples. A cylindrical grinding device suitable for reducing shafts, composed as figure 1 As shown, it includes a worktable 1. Both ends of the top of the worktable 1 are respectively provided with a driving wheel set 2 and a driven wheel set 3, between the driving wheel set 2 and the driven wheel set 3, there is a grinding set located on the top side of the worktable 1 4. Both the driving wheel group 2 and the driven wheel group 3 are provided with a pressing wheel group 5; the driving wheel group 2 includes two first rotating wheels 6 arranged side by side on the worktable 1, one of which rotates first The end of the wheel 6 is connected with a drive motor 7. The driven wheel set 3 includes a horizontal plate 101 located below the workbench 1. The horizontal plate 101 is provided with a screw lift 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com