Extrusion molding process of plastic particles

A plastic granule extrusion molding technology, applied in the field of plastic granulation, can solve the problems of inconsistent size, low production efficiency, low energy utilization efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

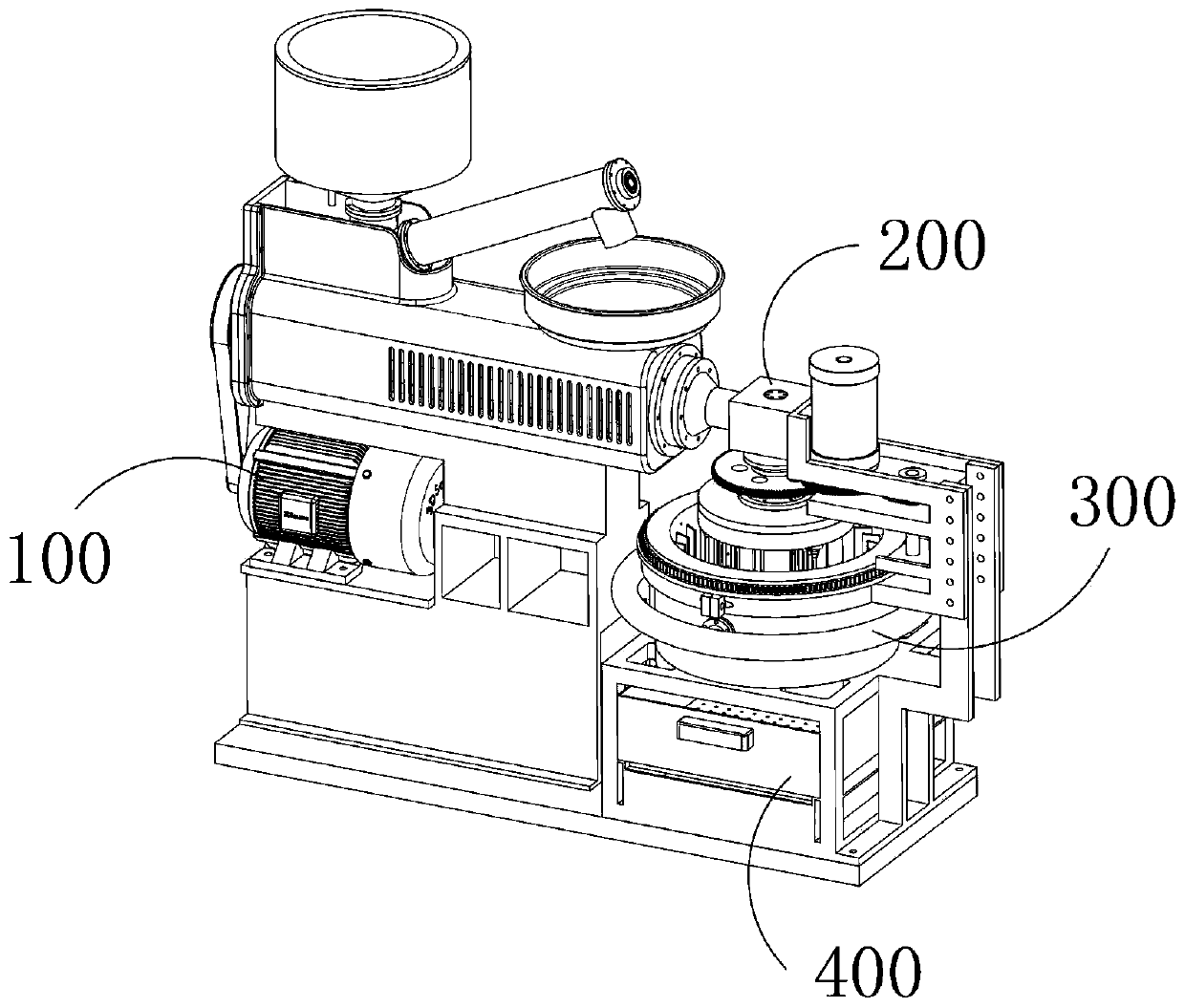

[0076] Plastic granule extrusion molding process, its steps are:

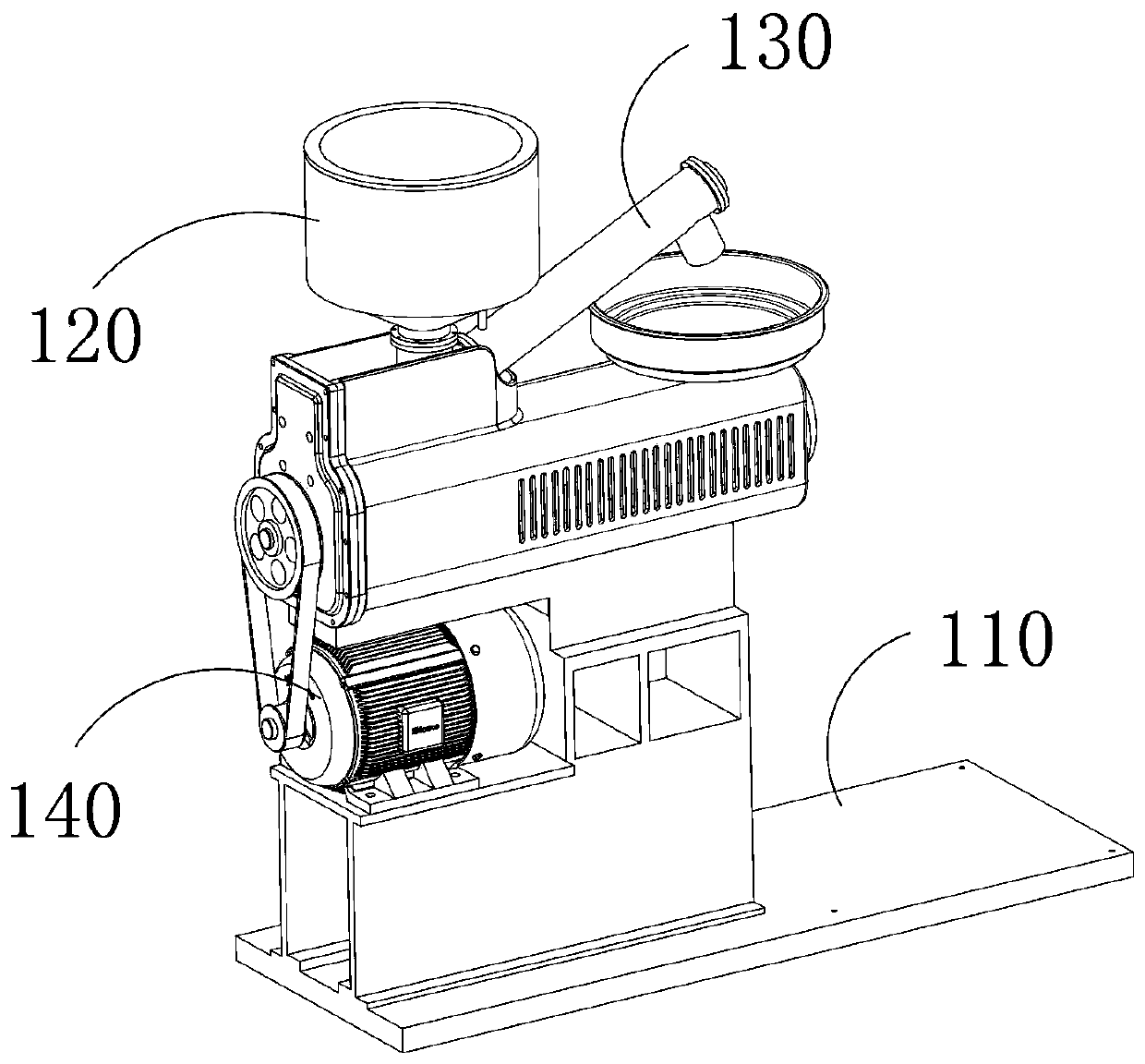

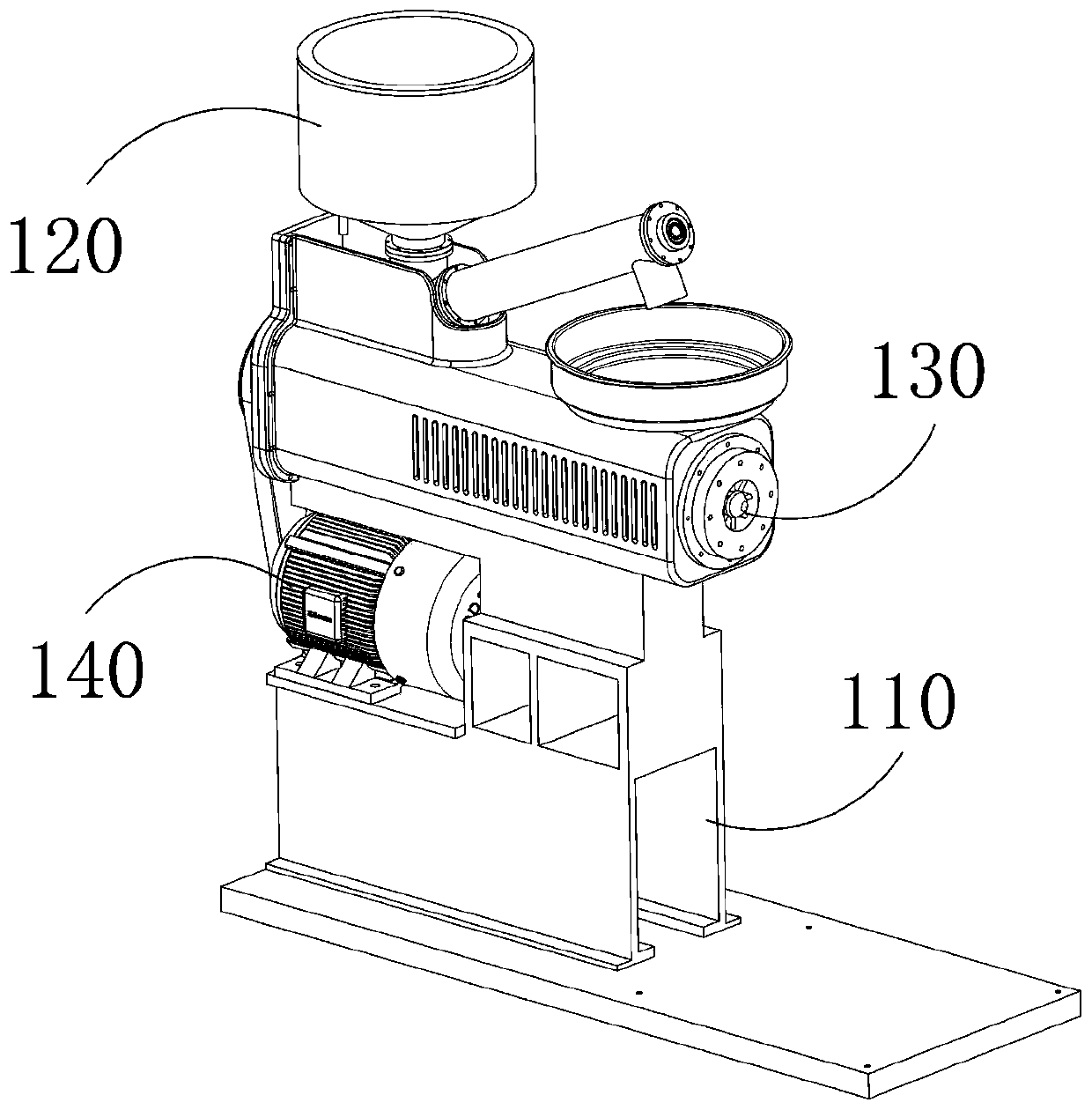

[0077] S1: The plastic melting device 100 sequentially melts the plastic fragments, filters impurities, and then transports the molten plastic to the particle forming device 200;

[0078] S2: The particle forming device 200 installed on the mounting bracket and coaxially located in the vortex water cooling device 300 receives molten plastic;

[0079] The vortex-type water cooling device 300 includes a water-cooling casing 310, a water pipe network 320, and a rotating mechanism 330. The water-cooling casing 310 includes an outer casing 311 and an inner casing 312. The outer casing 311 is fixed on the mounting bracket and has an open upper end and a lower end. Closed circular shell structure, the cavity bottom of the outer shell 311 is coaxially provided with a rotary groove in a ring groove structure, the inner shell 312 is a circular shell structure arranged coaxially with the outer shell 311 and has openings a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com