Nano-sheet-like ZSM-5 molecular sieve preparation method

A technology of ZSM-5 and nano flakes, which is applied in the field of preparation of nano flake ZSM-5 molecular sieves, can solve the problems of high synthesis cost and unfavorable industrial production, achieve large industrial application potential, reduce synthesis cost, and simplify synthesis steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Na in this example 2 O, Al 2 o 3 , SiO 2 , n-butylamine and H 2 The molar ratio of O is 0.08:0.01:1:0.15:30, and the seed crystal addition amount does not exceed SiO 2 10wt% of the content.

[0037] 1) According to SiO 2 with Na 2 O molar ratio is 3.2, 30wt% silica sol is pretreated with sodium hydroxide, and pretreated at 80°C for 24 hours. Add 0.15 g of sodium metaaluminate, 0.34 g of sodium hydroxide, and 0.66 g of n-butylamine to 24 g of water, stir and dissolve at room temperature, add 13.6 g of alkali-pretreated silica sol, and add concentrated sulfuric acid dropwise to adjust the pH value to 10.0 , and finally add 0.36 grams of ZSM-5 seed crystals;

[0038] 2) Stir and age at 100°C 200 rpm for 24 hours

[0039] 3) Raise the temperature to 170° C., react at 200 rpm for 72 hours, wash and dry to prepare ZSM-5 molecular sieve crystals.

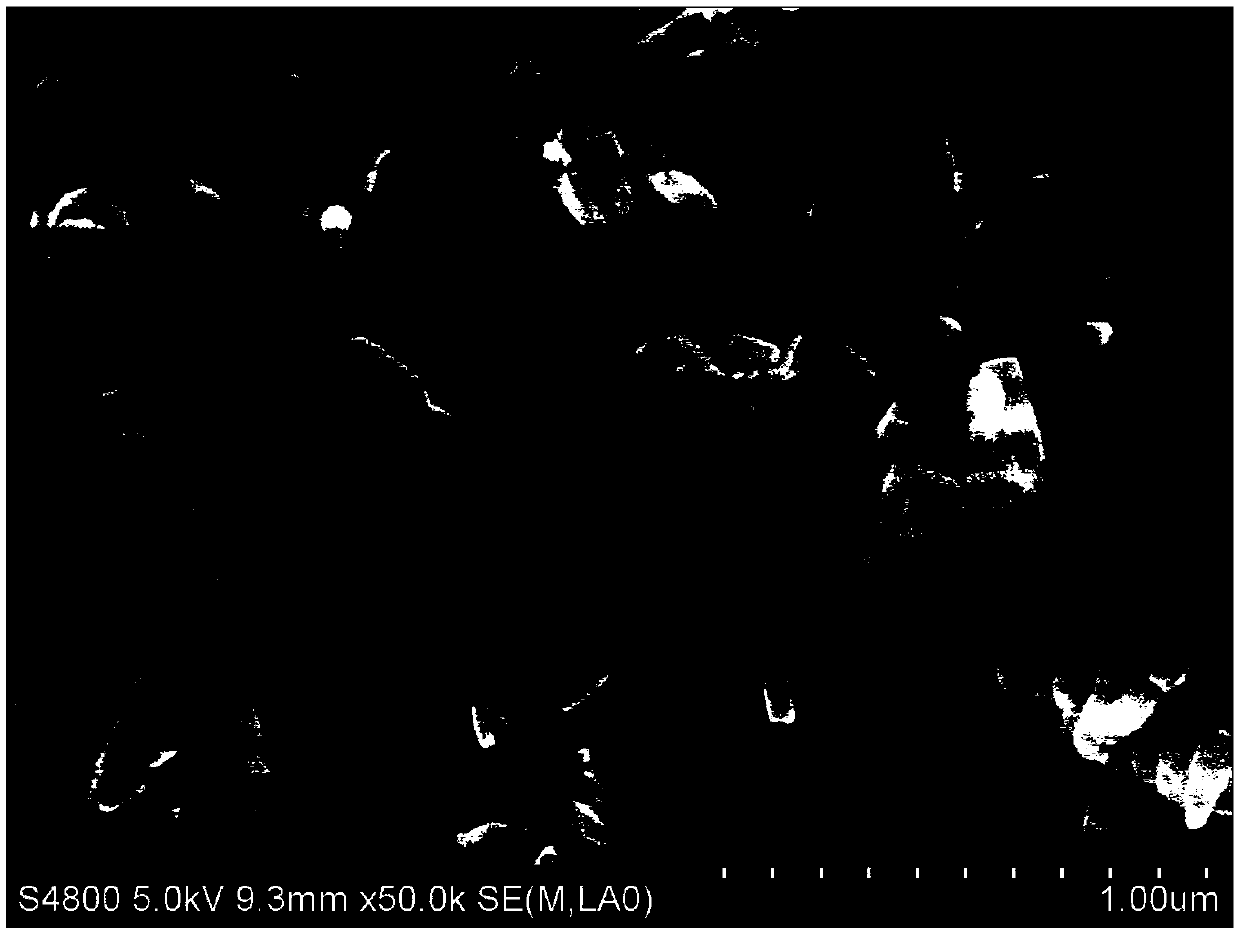

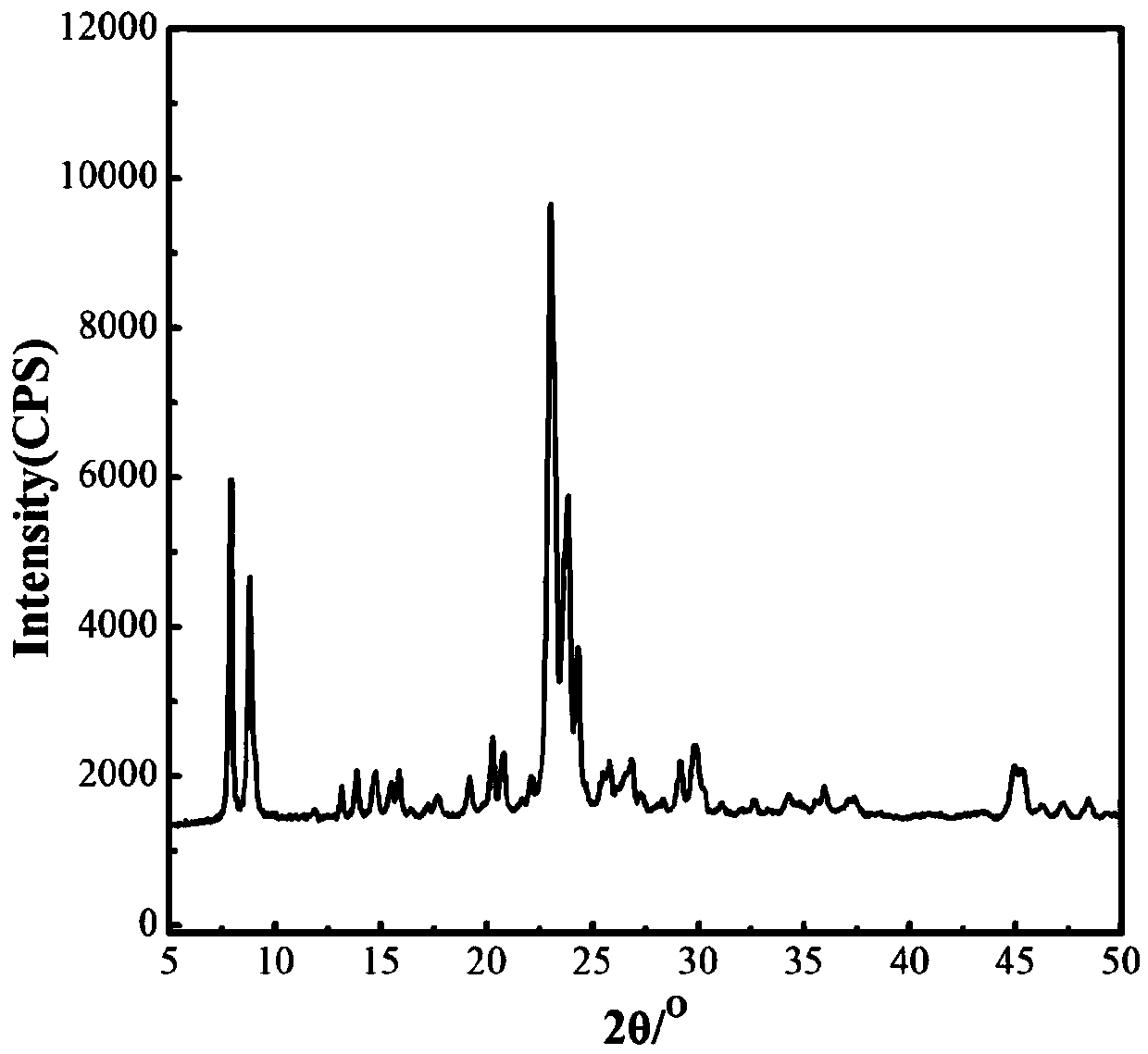

[0040] figure 1 Scanning electron micrograph of the ZSM-5 molecular sieve obtained by the preparation method. It can b...

Embodiment 2

[0048] Na in this example 2 O, Al 2 o 3 , SiO 2 , n-butylamine and H 2 The molar ratio of O is 0.08:0.01:1:0.15:30, and the seed crystal addition amount does not exceed SiO 2 30% of the content.

[0049] The difference with Example 1 is that step 1) joins 0.43 gram of aluminum sulfate octadecahydrate, 14.9 gram of water glass (modulus is 3), 0.7 gram of n-butylamine in 24 gram of water, stirring and dissolving at room temperature, then Concentrated sulfuric acid was added dropwise to adjust the pH to 9.5, and 1.08 g of ZSM-5 seed crystals were added. All the other steps are the same as in Example 1.

[0050] image 3 The SEM spectrum of the ZSM-5 molecular sieve obtained by the preparation method is a pure phase ZSM-5 molecular sieve with good crystallization. It can be seen that the crystal grains of the molecular sieve are well crystallized and the thickness is 50-100 nanometers.

Embodiment 3

[0052] Na in this example 2 O, Al 2 o 3 , SiO 2 , isopropylamine and H 2 The molar ratio of O is 0.15:0.05:1:0.2:100, and the seed crystal addition amount is 0.1%.

[0053] The difference from Example 1 is that step 1) add 0.75 grams of sodium metaaluminate and 0.72 grams of isopropylamine to 100 grams of water, stir and dissolve at room temperature, then add 13.6 grams of alkali to treat the silica sol dropwise, and add concentrated sulfuric acid dropwise Adjust the pH to 11.5 and add 0.004 g of ZSM-5 seed crystals. All the other steps are the same as in Example 1.

[0054] Figure 4 The SEM spectrum of the ZSM-5 molecular sieve obtained by the preparation method is a pure phase ZSM-5 molecular sieve with good crystallization. It can be seen that the crystal grains of the molecular sieve are well crystallized and the thickness is 50-100 nanometers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap