Infrared Generating Network

An infrared and mesh technology, applied in the burner, combustion type, combustion method, etc., can solve the problems of inability to effectively increase the infrared scattering surface area, increase the fire temperature, and inability to increase the infrared scattering range and intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

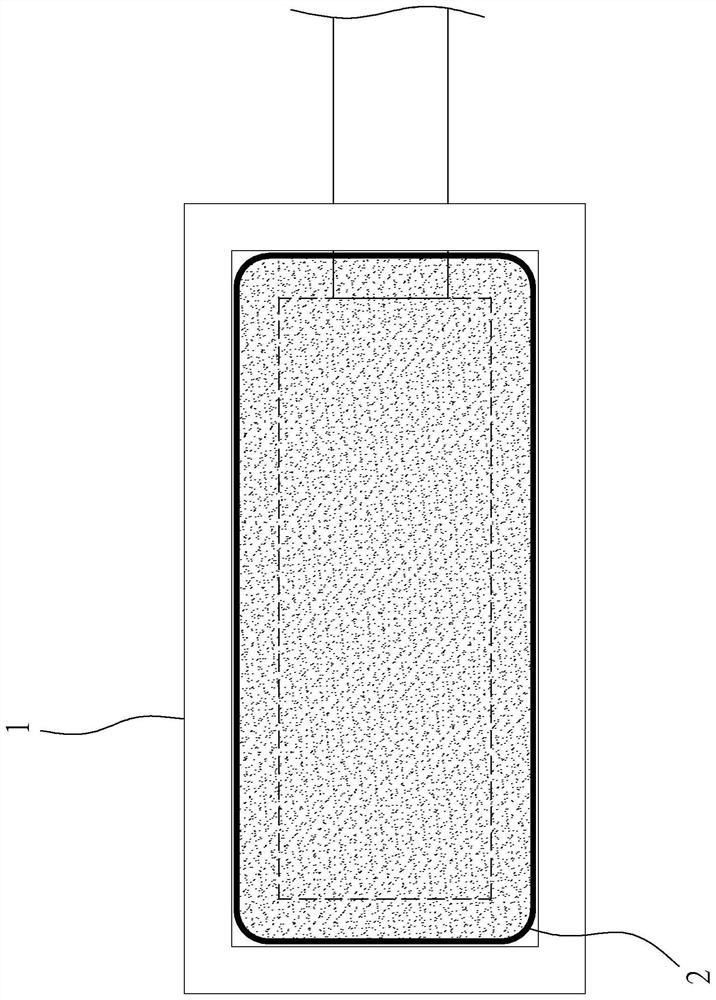

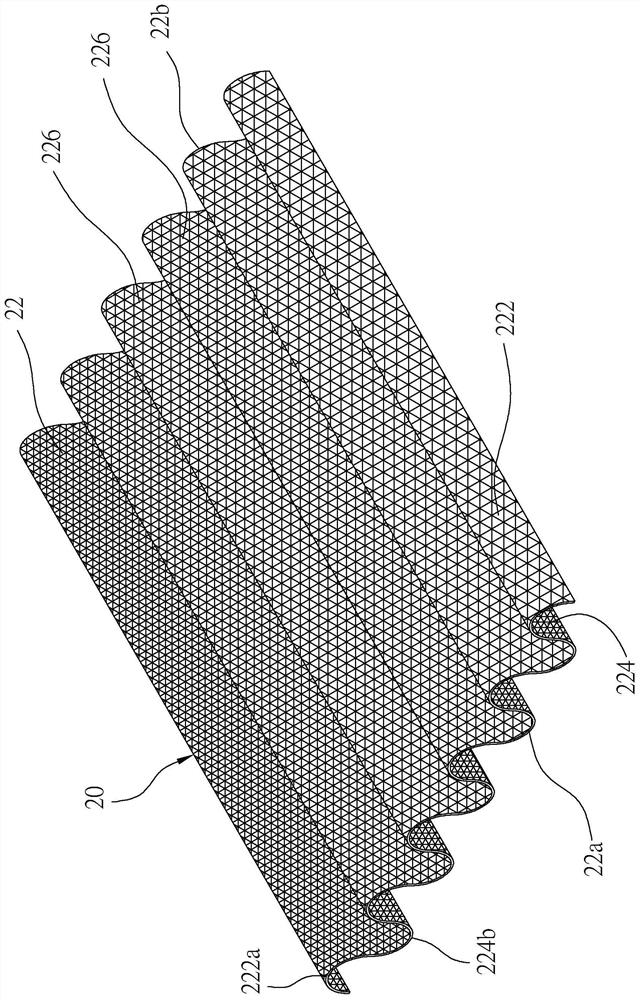

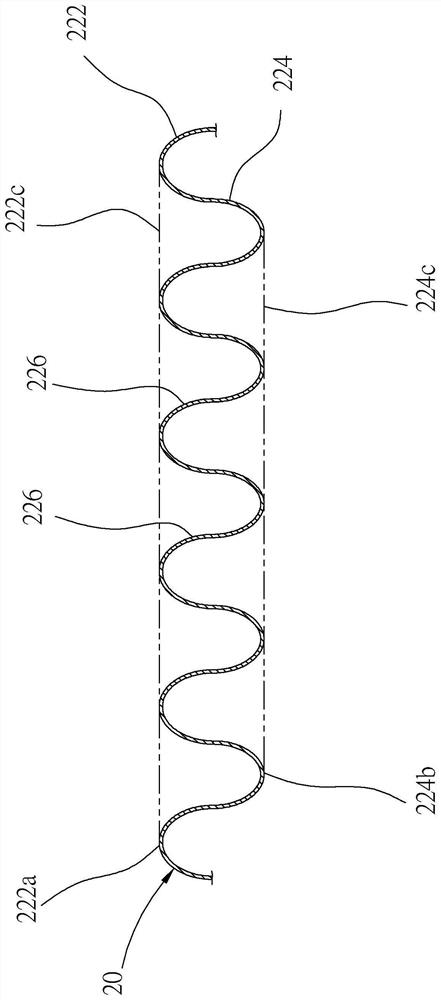

[0023] In order to illustrate the present invention more clearly, preferred embodiments are given and detailed descriptions are given below in conjunction with drawings. Please refer to Figure 2 to Figure 3 Shown is the infrared ray generating net 20 of the first preferred embodiment of the present invention

[0024] Such as figure 2 As shown, the infrared generating net 20 is made of metal, which is iron-chromium-aluminum alloy in this embodiment. The infrared generating net comprises a rectangular mesh body 22, which has a first surface 222 and a second surface 224 opposite to each other, and a periphery; the first surface 222 is not shielded and exposed to the outside , the peripheral edge has four edges, and two opposite edges form a first portion 22a and a second portion 22b. In actual production, the periphery of the mesh body 22 can also be circular, and the periphery of the mesh body 22 can be divided into two halves with a circular diameter, wherein the first par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com