A positioning control method for the shaft and rudder system segmented loading of a ship with two propellers and two rudders

A technology of positioning control and shaft rudder system, which is applied in the direction of ships, etc., can solve the problems of complex internal environment, inability to form a unified standard system, on-site intuitive guidance, and many cross-dimensional operations, so as to achieve unified positioning benchmarks, improve the positioning accuracy of onboard vehicles, and The effect of loading efficiency and simplifying the positioning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below we combine the drawings and specific embodiments to further elaborate on the positioning control method of the shaft and rudder system of the ship of the double propeller and double rudder type ship of the present invention, in order to understand its structural composition and working mode more clearly, but cannot In this way, the protection scope of the present invention is limited.

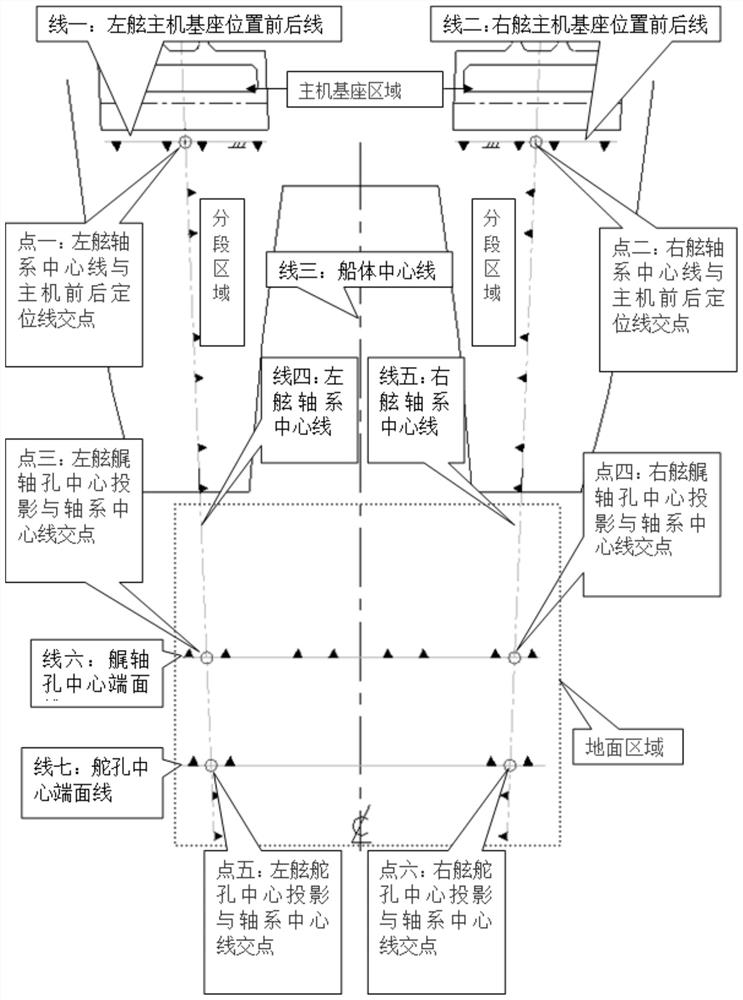

[0027] The present invention associates the dual-axis system and the double-rudder system in sections through the drawing of the "six points and seven lines" grid line, and each axis-rudder system is independently positioned according to the ground sample line, which can ensure the accuracy of the dual-axis rudder system. Equipped with precision control requirements. Now let’s take a step-by-step positioning as an illustration. The detailed steps are as follows:

[0028] The first step is to complete the host segment loading. According to the parameter information of the design d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com