Sewage treatment device for quickly separating impurities

A technology for sewage treatment device and impurities, which is applied in the field of sewage treatment devices for rapidly separating impurities, can solve the problems of simple structure, poor filtering effect, and influence on water passability, so as to reduce the frequency of maintenance and cleaning, increase the contact area, and reduce the use cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

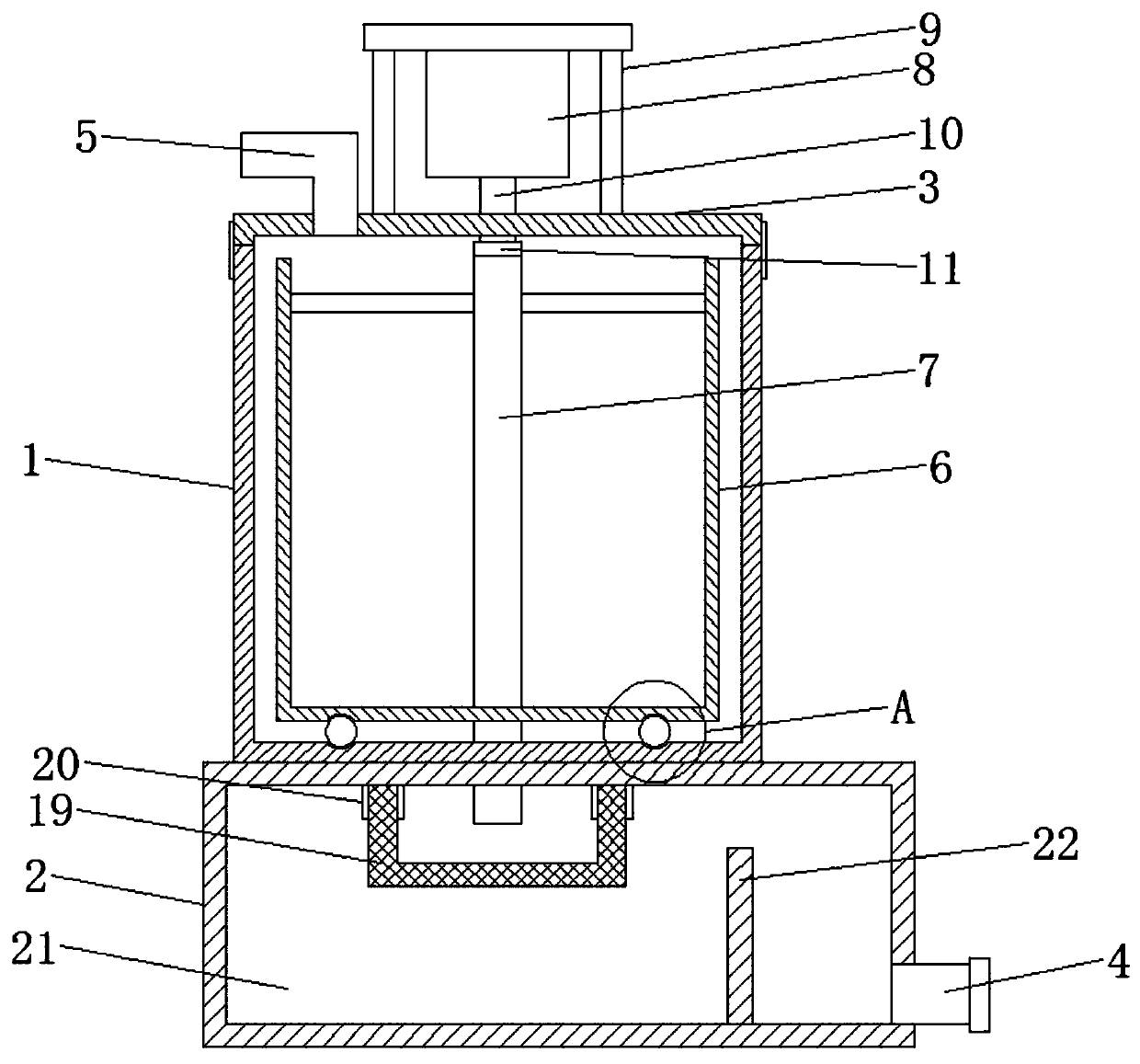

[0021] Please refer to the figure, in the embodiment of the present invention, a sewage treatment device for quickly separating impurities includes a housing 1, a sedimentation tank 2, an upper cover 3, a drain pipe 4 and a water inlet pipe 5; the housing 1 is fixedly installed in the sedimentation tank On the top of the box 2, the upper cover 3 is detachably installed on the top of the housing 1, and the housing 1 is opened through the upper cover 3 to facilitate internal cleaning. The upper cover 3 is connected with a water inlet pipe 5, and the sewage flows from the water inlet pipe. 5 into the housing 1, and the bottom of the settling tank 2 is communicated with a drain pipe 4, through which the water after removal of impurities is discharged.

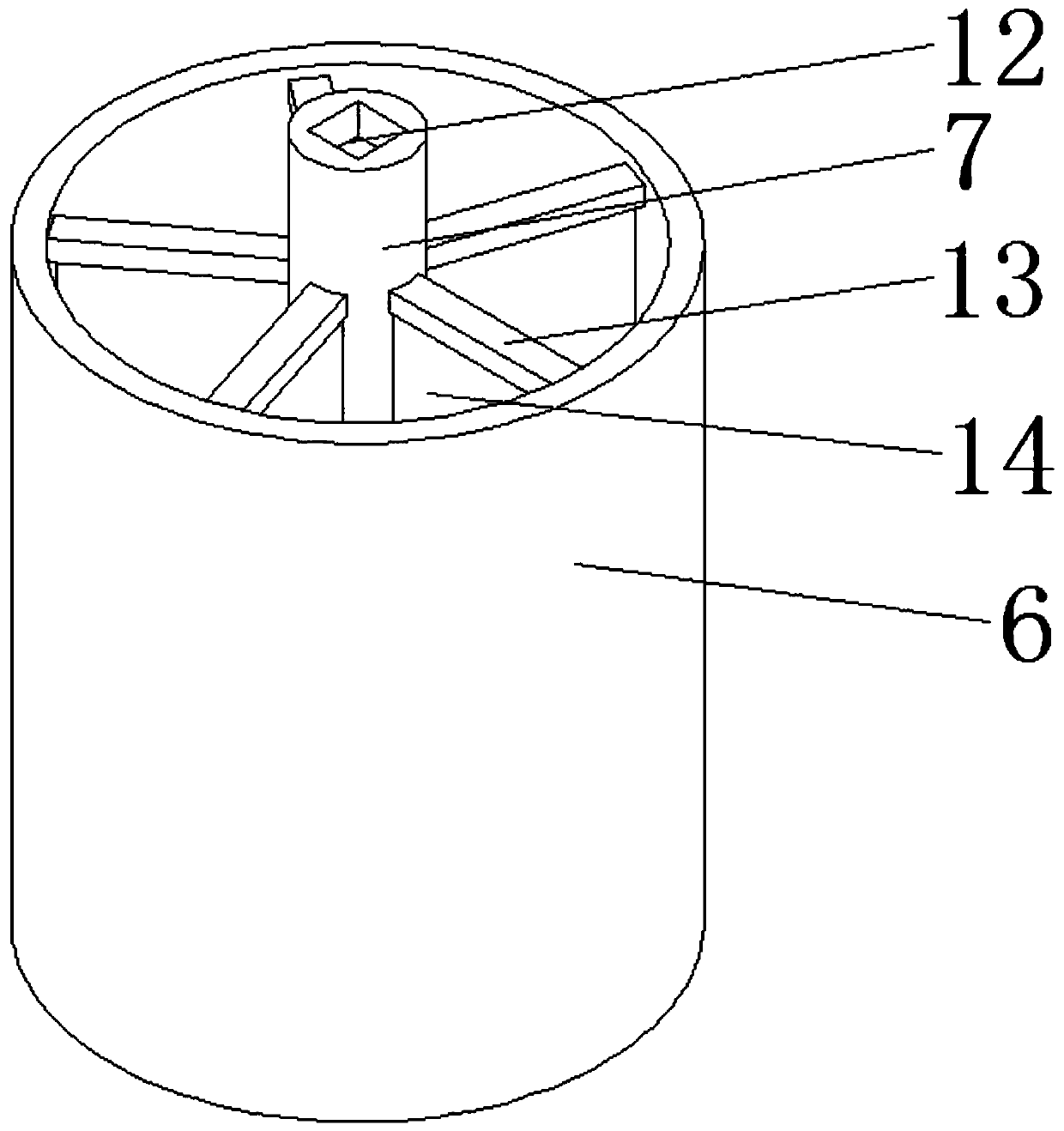

[0022] The upper surface of the upper cover 3 is equipped with a vertical motor 8, and is fixed on the upper cover 3 by a motor bracket 9; the output shaft of the motor 8 is vertically downward, and its lower end is coaxially fixed ...

Embodiment 2

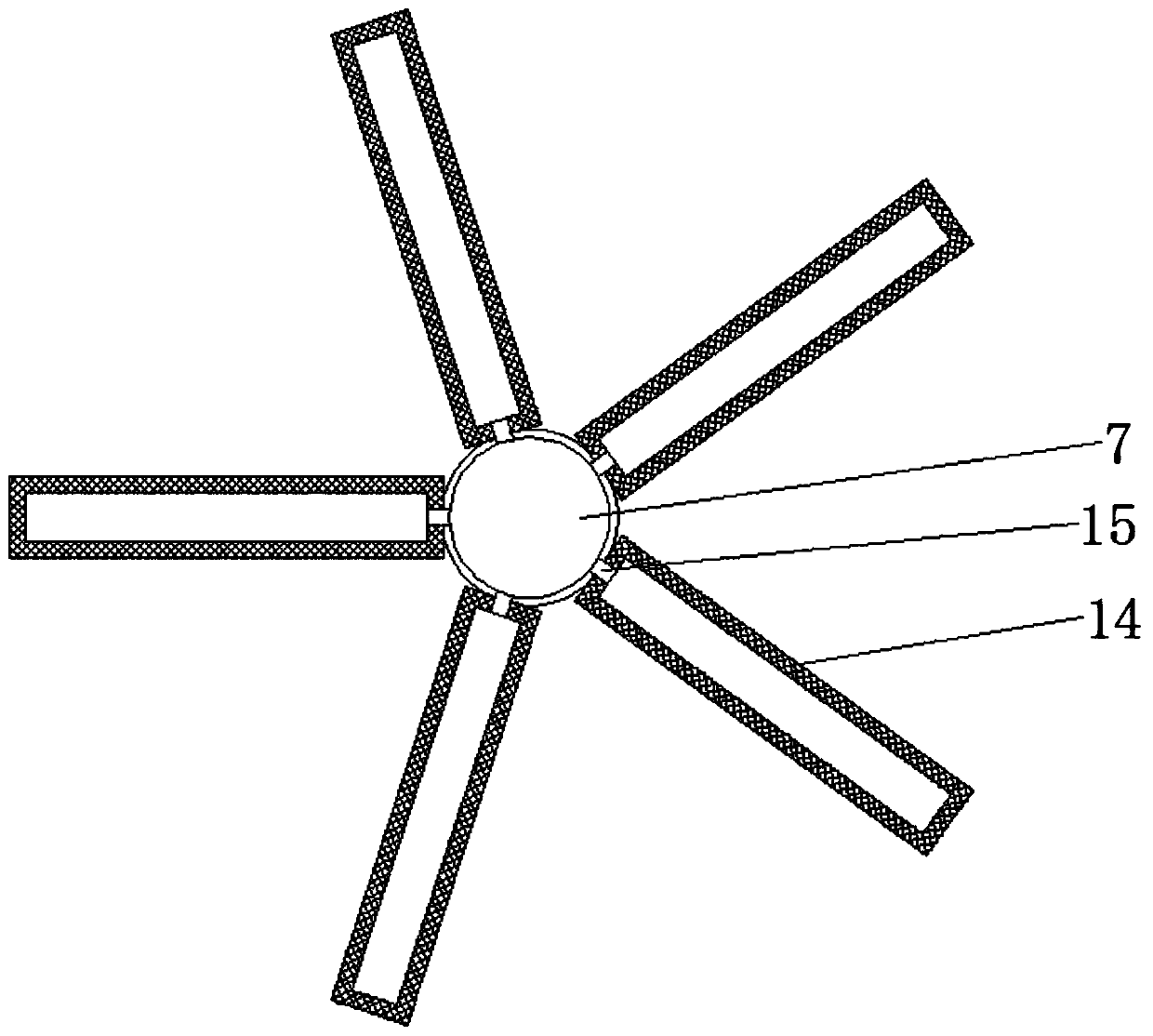

[0025] On the basis of Embodiment 1, the filter screen box 14 is made of rigid materials, such as stainless steel mesh panels, etc., which has high support strength and is easier to contact and filter water.

[0026] When cleaning the sewage, the sewage is passed into the casing 1 from the water inlet pipe 5, and falls into the rotating cylinder 6 in the casing 1. The rotating cylinder 6 rotates inside, and the sewage is filtered through the moving filter box 14. The filtered water flows into the hollow shaft 7 from the drainage hole 15, and the filtered impurities remain in the rotating cylinder 6, and the rotating cylinder 6 rotates and moves to make the surrounding sewage flow, reducing the blockage of the impurities on the mesh, which can Regularly adjust the motor 8 to change the direction of rotation, which is easy to filter and reduces the maintenance frequency of the equipment; the filtered water flows into the sedimentation tank 2, and the deceleration effect of the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com