An anchor bolt roughening device

A technology for anchor bolts and mounting brackets, applied in the directions of bolts, feeding devices, positioning devices, etc., can solve problems such as reducing the pullout resistance of the tower, reducing the product life cycle, and loosening the nuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

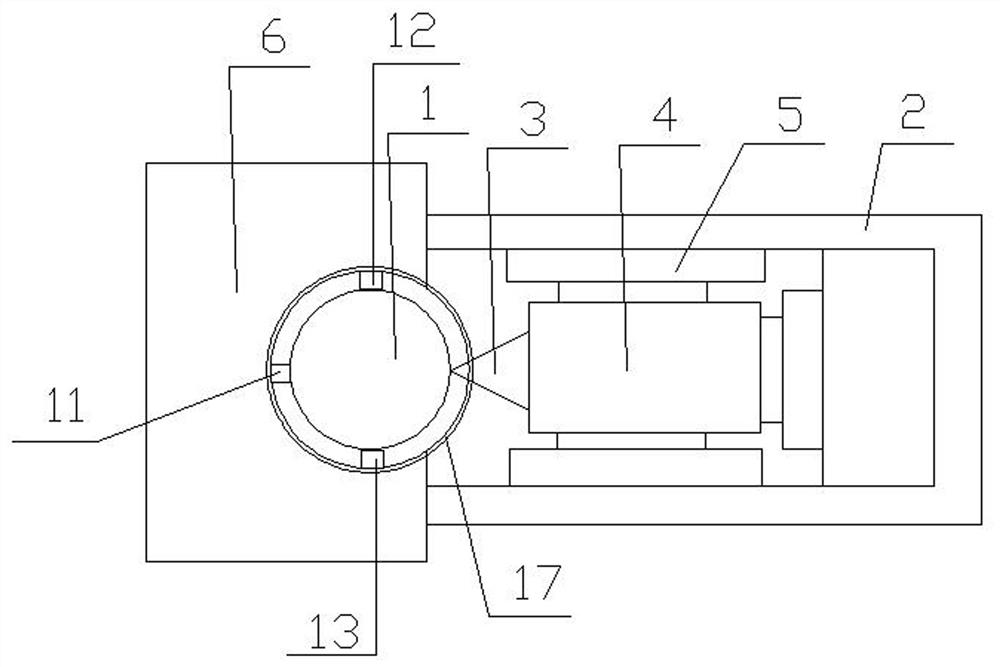

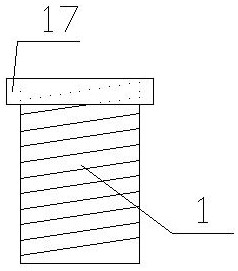

[0023] like figure 1 As shown, a ground bolt 1 fur, including mounting frame 2, top stroke 3, is used to drive drive mechanisms and bolts automatic clamping mechanisms in the left-right direction of the top head;

[0024] The drive mechanism is fixedly coupled to the mounting frame 2, and the fixed end of the top head 3 is fixed to the power output of the drive mechanism;

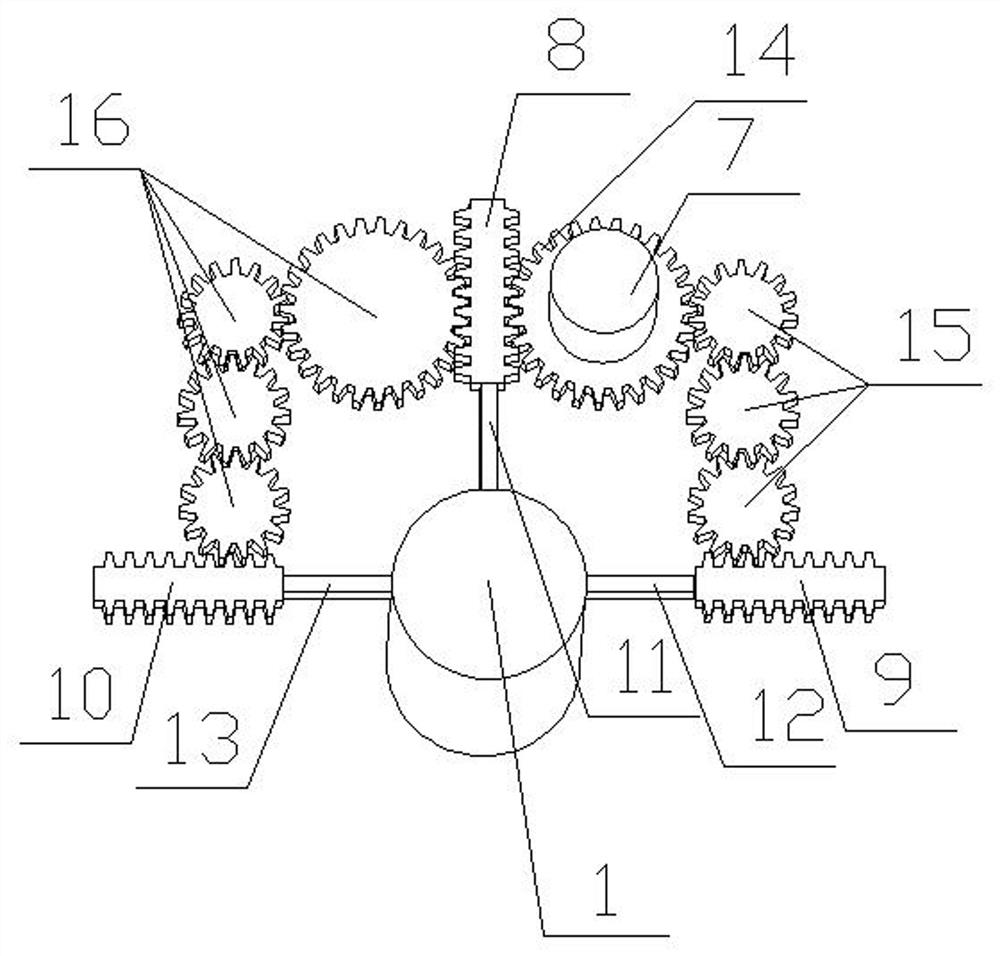

[0025] The bolt automatic clamping mechanism includes a housing 6, a plurality of clamping rods for driving a plurality of clamping rods along the radially extended drive motor 7 and a transmission; the plurality of clamp rods , The drive motor 7 drives a plurality of clamping rods in the radial direction by the transmission mechanism; the transmission mechanism and the drive motor 7 are disposed inside the housing 6, and the drive motor 7 is fixedly connected to the housing 6. The housing 6 is fixed to the mounting frame 2.

[0026] The drive mechanism employs a hydraulic jack 4, the power output end of the hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com