Static pressure pile sinking device capable of adopting interior through method, and internal through static pressure pile sinking method

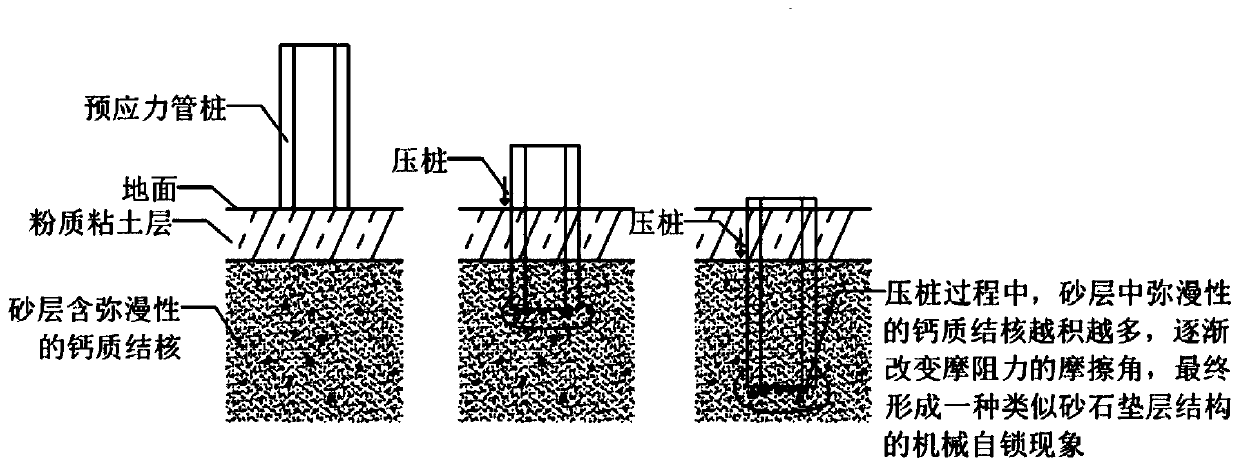

A medium-pass method and static pressure technology, which is applied to sheet pile walls, buildings, and foundation structure engineering, etc., can solve problems such as too short piles, piles that cannot reach the pile length, and single pile bearing capacity cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

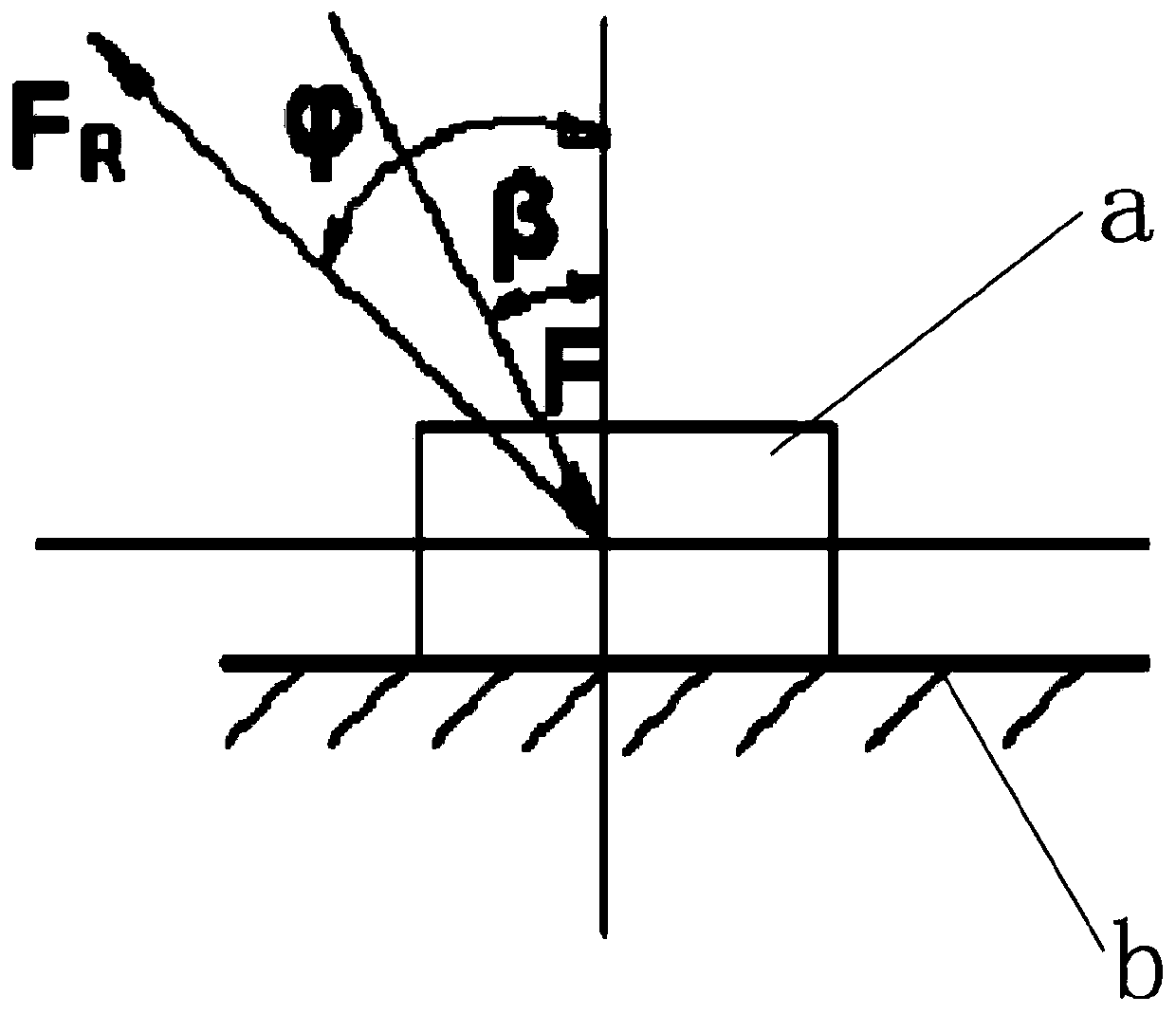

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

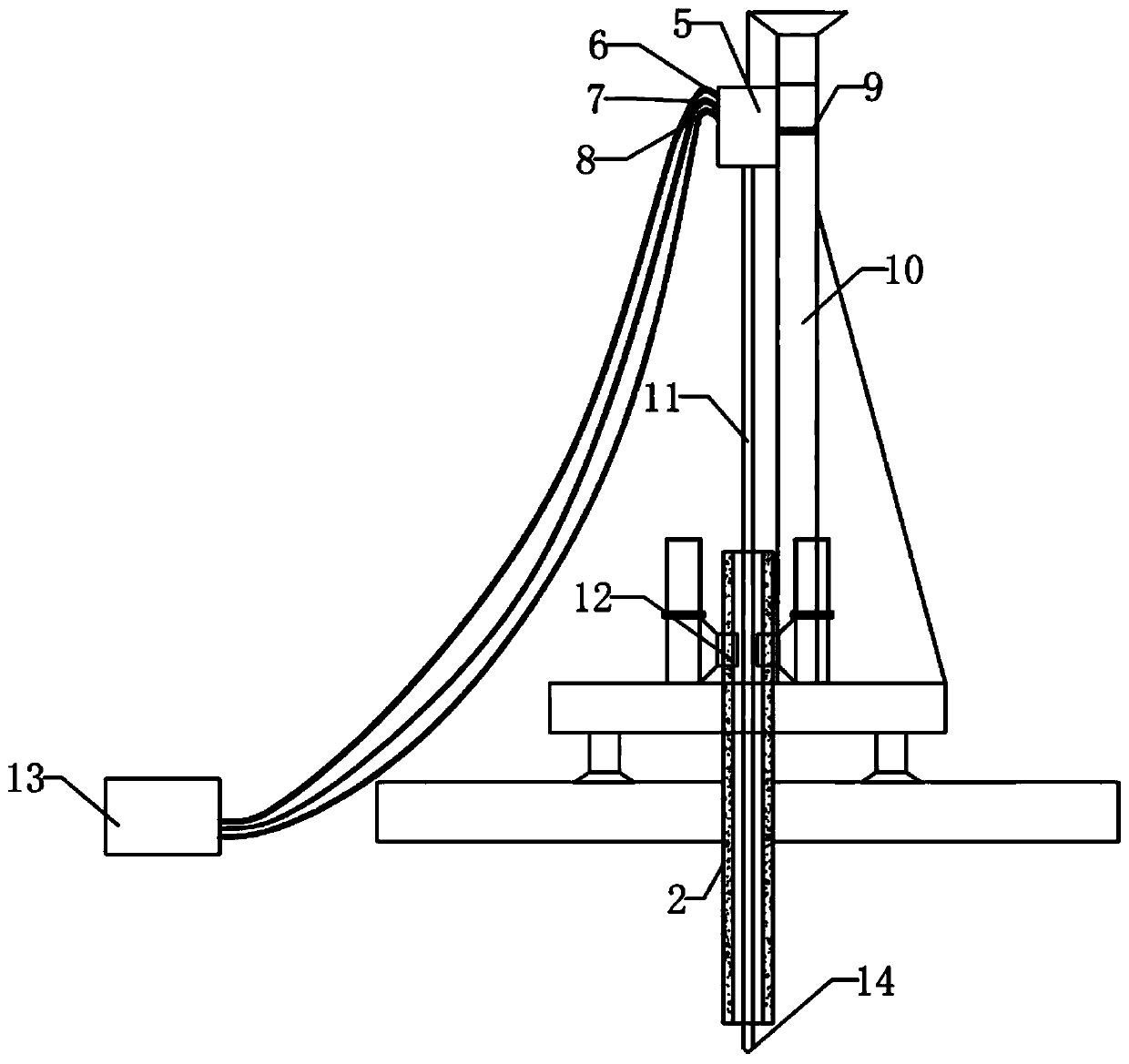

[0036]In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the following briefly introduces the drawings required for the description of the embodiments or the prior art. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other embodiments according to these drawings without creative efforts.

[0037] Such as Figure 3-Figure 5 Shown is a schematic structural view of a preferred embodiment of the static pressure pile sinking device using the Zhongtong method according to the present invention. One aspect of the present invention provides a static pressure pile sinking device adopting the middle-pass method, comprising a prestressed pipe pile 2, a column frame 10, a hollow drill rod 11 and a drill bit 14 arranged at the end of the drill rod. An inner conduit 3 is provided in the inner cavity of the pipe pile 2, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com